Long-acting totally-closed water seal type odor-resistant same-floor drainage floor drain

A kind of same-layer drainage, fully enclosed technology, applied in drainage structures, waterway systems, water supply devices, etc., can solve problems such as lack of anti-drying effect, inconvenient installation and maintenance, and inability to achieve smooth drainage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

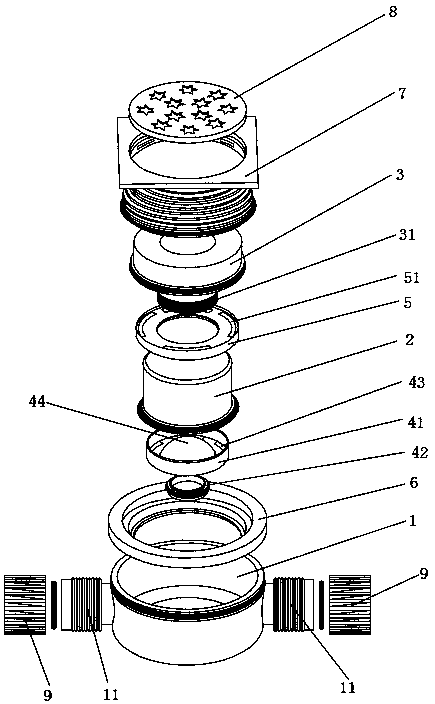

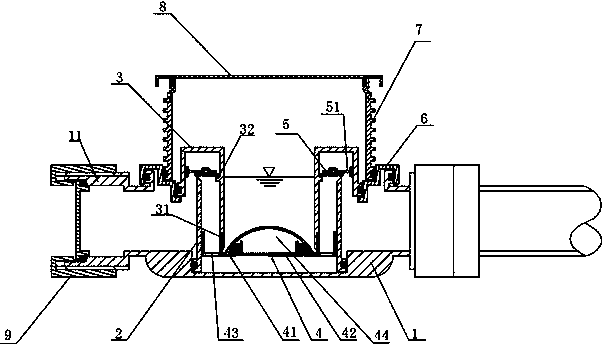

[0035] figure 1 and 2 The shown long-term fully enclosed water-sealed and deodorant floor drain on the same floor includes a floor drain body 1 on the same floor, a floor drain grate 8 and a water seal structure. Pipeline interfaces 11, the two pipeline interfaces 11 are provided with pipe connectors 9 for connecting with drainage pipes. The upper opening of the floor drain main body 1 is provided with a top cover 6 for positioning and installation. In order to adapt to the different floor thickness of the floor drain installation and the different installation depths of the drain pipes on the same floor, a height-adjustable tubular grate connector 7 is provided between the floor drain grate 8 and the installation position of the top cover 6, and the outer wall of the grate connector 7 is There are several annular grooves, and the grate connector 7 of a suitable height can be intercepted according to the height of the floor drain when it is installed, so that there is a dis...

Embodiment 2

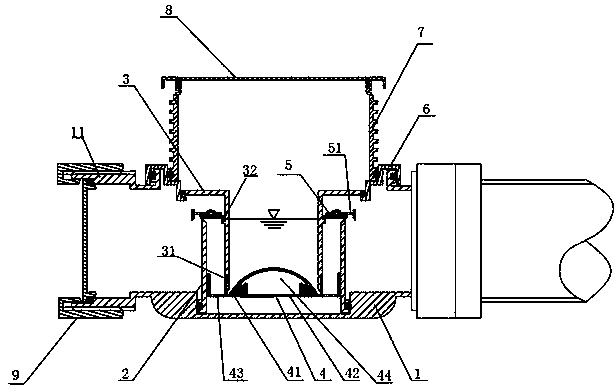

[0043] like image 3 As shown, the difference from Embodiment 1 is that the upper edge of the cylindrical water-sealed inner sleeve 3 has an outer flange, and the outer diameter of the outer flange is larger than the outer diameter of the water-sealed overcoat 2, and the outer edge of the outer flange is detachable. The type seal is connected to the second step of the top cover 6.

Embodiment 3

[0045] like Figure 4 As shown, the difference from Embodiment 1 or 2 is that the middle part of the floor drain grate 8 is provided with a through hole for passing through the outlet pipe of the washing machine. A pipe pinch sealing ring 82 is set, and an annular overflow-proof plate 10 capable of sealing the hole area of the grate is arranged below the floor drain grate 8. Support, when the amount of water entering the floor drain is large and cannot be discharged in time, the anti-overflow plate 10 rises to contact the grate under the buoyancy and impact of the water, and closes the holes on the floor drain grate 8 to prevent water from flowing out of the floor drain grate. The hole on the child 8 overflows to the ground.

[0046] The anti-overflow plate 10 is made of an annular hollow base and an annular sealing ring fixed to the top surface of the base, and the annular sealing ring contacts and seals the floor drain grate 8 hole area part with the bottom surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com