A glass fiber reinforced plastic composite packaging box

A technology of composite materials and packaging boxes, which is applied in packaging, transportation and packaging, rigid containers, etc., can solve the problems that the strength and rigidity cannot meet the requirements of transportation, easy deformation, cracking, etc., to improve product economy, increase strength, The effect of improving performance status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

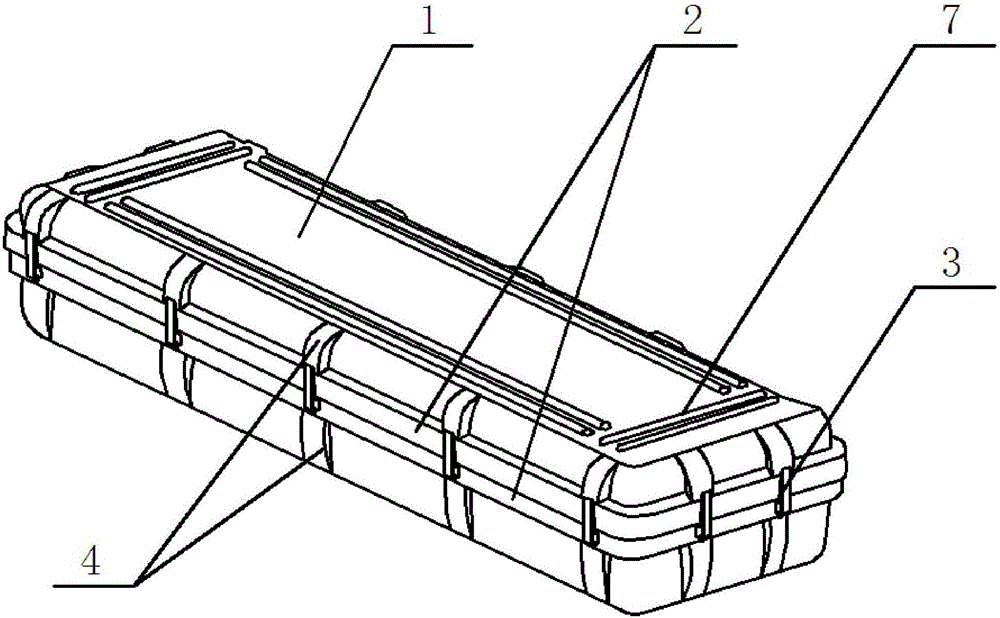

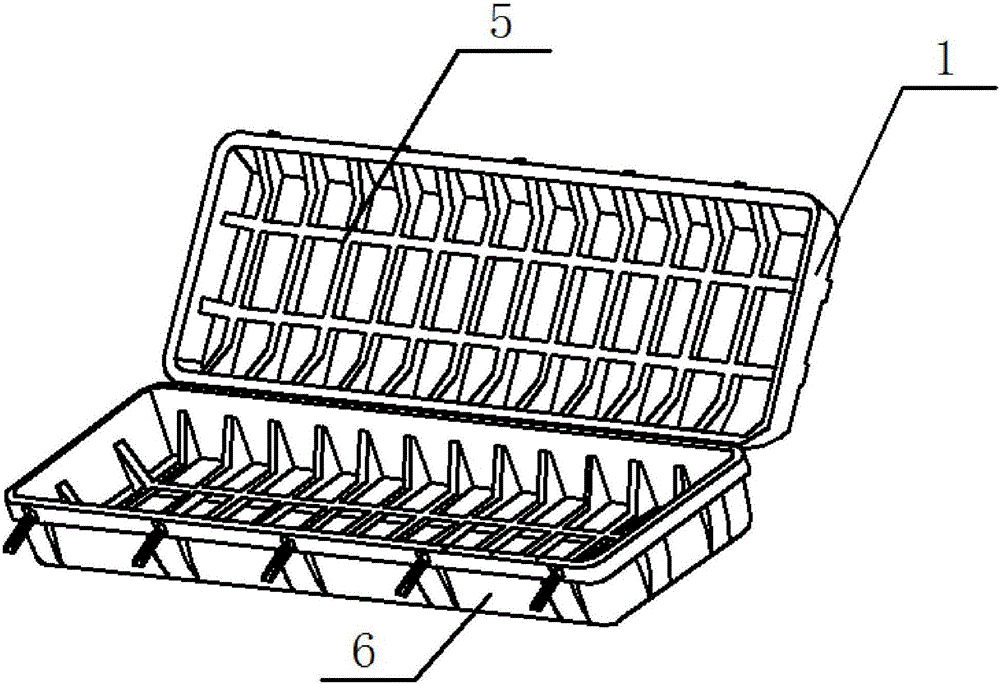

[0030] A glass fiber reinforced plastic composite packaging box, comprising an upper box 1, a lower box 6 located below the upper box 1, and a lock 3 capable of locking the upper box 1 and the lower box 6, and the upper box 1 The closed edge of the lower box body 6 is provided with a circular convex reinforcing rib 2, and the circular convex reinforcing rib 2 is provided with an arc-shaped convex reinforcing rib 4. Arc-shaped convex reinforcing ribs 4 are arranged on the upper box body 1 and the lower box body 6, five on the long side of the box body, two on the short side, and symmetrically arranged, one side of which is aligned with the circumferential convex The reinforcing ribs 2 are connected, and the other side is connected with the surrounding surface of the upper box body 1 or the lower box body 6; the arc-shaped convex reinforcing ribs 4 are arranged symmetrically on each group of opposite sides. The convex height of the connecting surface between the arc-shaped conve...

Embodiment 2

[0032] A glass fiber reinforced plastic composite packaging box, comprising an upper box 1, a lower box 6 located below the upper box 1, and a lock 3 capable of locking the upper box 1 and the lower box 6, and the upper box 1 The closed edge of the lower box body 6 is provided with a circular convex reinforcing rib 2, and the circular convex reinforcing rib 2 is provided with an arc-shaped convex reinforcing rib 4. Arc-shaped convex reinforcing ribs 4 are arranged on the upper box body 1 and the lower box body 6, five on the long side of the box body, two on the short side, and symmetrically arranged, one side of which is aligned with the circumferential convex The reinforcing ribs 2 are connected, and the other side is connected with the surrounding surface of the upper box body 1 or the lower box body 6; the arc-shaped convex reinforcing ribs 4 are arranged symmetrically on each group of opposite sides. The convex height of the connection surface between the arc-shaped conve...

Embodiment 3

[0034] A glass fiber reinforced plastic composite packaging box, comprising an upper box 1, a lower box 6 located below the upper box 1, and a lock 3 capable of locking the upper box 1 and the lower box 6, and the upper box 1 The closed edge of the lower box body 6 is provided with a circular convex reinforcing rib 2, and the circular convex reinforcing rib 2 is provided with an arc-shaped convex reinforcing rib 4. Arc-shaped convex reinforcing ribs 4 are arranged on the upper box body 1 and the lower box body 6, five on the long side of the box body, two on the short side, and symmetrically arranged, one side of which is aligned with the circumferential convex The reinforcing ribs 2 are connected, and the other side is connected with the surrounding surface of the upper box body 1 or the lower box body 6; the arc-shaped convex reinforcing ribs 4 are arranged symmetrically on each group of opposite sides. The convex height of the connecting surface between the arc-shaped conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com