An aircraft engine installation device

A technology for aircraft engines and installation equipment, which is applied in the field of mechanical products and aircraft manufacturing. It can solve the problems of operability, convenience and safety that cannot fully meet the requirements of users, and solve the safety hazards of easy breakage and corrosion. Accurate positioning, the effect of improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

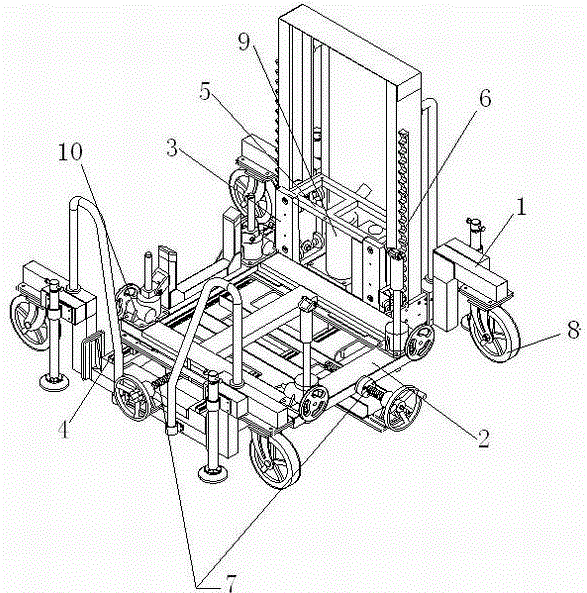

[0021] Attached below figure 1 A detailed description of the present invention:

[0022] An aircraft engine installation equipment, which includes a base 1, a moving bracket 2, an L-shaped bracket 3, a guide rail placement assembly 4, a lifting mechanism 5, a locking mechanism 6, and an adjustable screw rod 7,

[0023] The guide rail placement assembly 4 is installed between the L-shaped bracket 3 and the motion bracket 2;

[0024] The four ends of the base 1 are equipped with movable casters 8;

[0025] Adjustable screw rods 7 are provided on four sides of the moving bracket 2;

[0026] The locking mechanism 6 is used to limit and fix the L-shaped bracket 3 and the lifting mechanism 5;

[0027] The lift 10 is installed on the sports bracket 2;

[0028] The jack 9 is installed on the base 1. The installation device can move through the jack 9 on the base 1 to realize the ascending and descending movements of the L-shaped bracket.

[0029] The base 1 is a frame structure welded by section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com