Men's front and back ventilated leather shoes

A front-to-back ventilation and breathable technology, applied in shoe uppers, footwear, boot legs, etc., can solve the problems that sweat cannot be ventilated and air-dried in a short time, shorten the service life of leather shoes, and the wearing process is difficult, so as to reduce foot sweating. , The effect of ventilation is significant, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

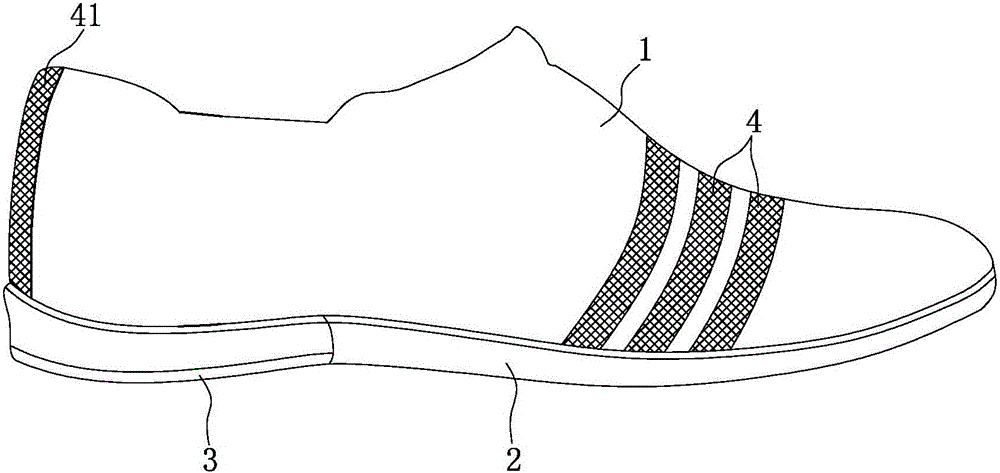

[0016] Such as figure 1 As shown, the present invention is composed of three parts: upper 1, sole 2 and heel 3. The sole 2 and heel 3 are integrally structured and made of high-strength wear-resistant plastic. There are semicircular protrusions for massaging distributed on the top, and the front end of the sole 2 and the rear end of the heel 3 are both upturned. The upper 1 is located above the sole 2 and is made of leather. The shape of the upper 1 and the connection with the sole 2 are the same as those of the prior art, and will not be repeated here.

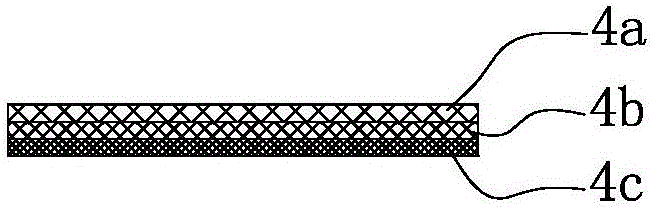

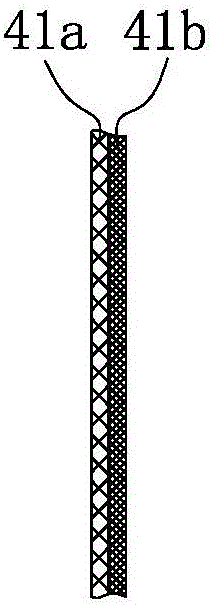

[0017] Such as figure 1 , figure 2 , image 3 As shown, there are 2-4 first openings with a width of 10-20mm from front to back at the front of the shoe upper 1, and the first openings extend from the left side of the shoe sole 2 to the right side along the curved surface of the shoe upper. There are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com