A line card fixing method for the output line of LED street lamp power supply

A technology for LED street lamps and power output, which is applied to light sources, semiconductor devices of light-emitting elements, lighting devices, etc., can solve the problems that lamps cannot be lit normally, the production process is perfect, and the output wire is welded, so as to avoid poor contact, Low production cost and easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

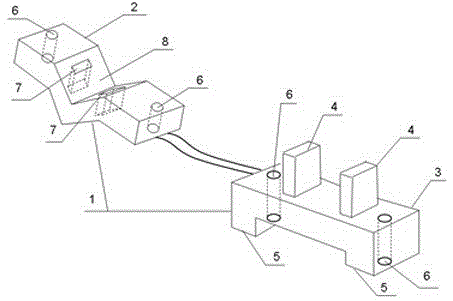

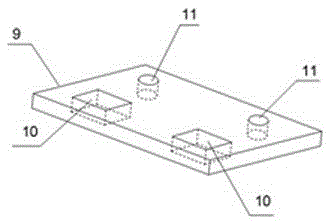

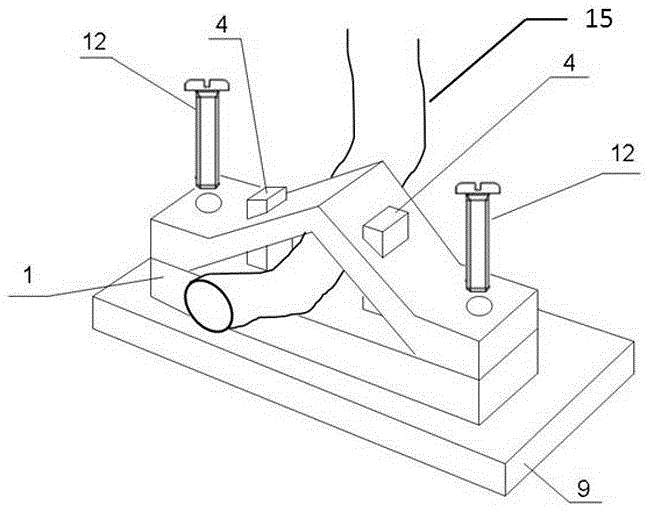

[0014] Accompanying drawing is a kind of specific embodiment of the present invention. This invention is used for the line card fixing method of the LED street lamp power supply output line, and uses the combined plastic line card 1, the line card fixing screw 12, the line card fixing plate 9, and the fixing plate fixing screw 13 to realize the fixing of the power output line 15, Among them, the line card fixing screw 12, the line card fixing plate 9 and the fixing plate fixing screw 13 are all made of stainless steel. The combined plastic line card 1 includes the line card cover 2, the base 3 and the connecting wires connecting these two parts. The line card cover 2 There is a V-shaped groove 8 in the middle, and there are cable card screw fixing holes 6 on both sides. There are square holes 7 on the two groove walls of the V-shaped groove 8. There are two guide rods 4 on the top of the base 3. The outer sides of the guide rods 4 There are screw fixing holes 6 for the cable c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com