Oil pipeline leakage detection and positioning method based on comprehensive signals

A positioning method and leak detection technology, which is applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems such as the pressure inflection point is not obvious, no positioning, leakage alarm, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

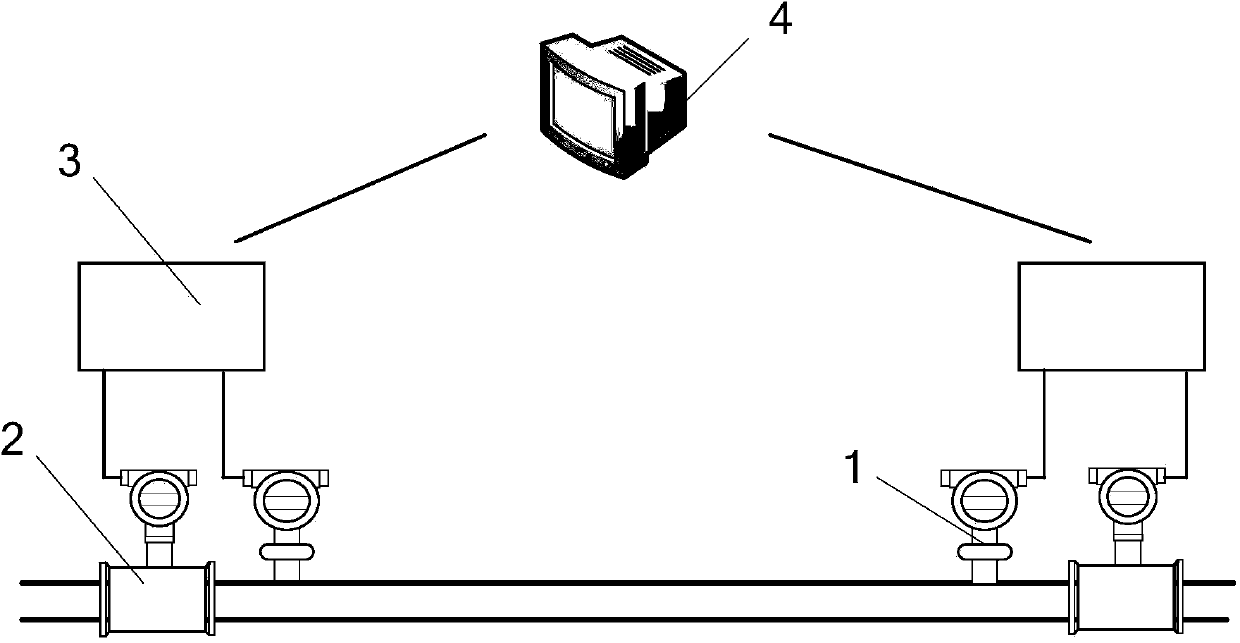

[0036] In this example, refer to Figure 1 to Figure 5 As shown, a method for detecting and locating oil pipeline leaks based on integrated signals, the hardware structure used in the method for detecting and locating oil pipeline leaks based on integrated signals includes a pressure transmitter 1, a flow meter 2, a data collector 3 and Control Terminal 4. The flow meter is preferably a mass flow meter.

[0037] Specifically include the following steps:

[0038] A. Data acquisition and integrated signal calculation

[0039] 1) The pressure and flow at the beginning and end of the pipeline are converted into electrical signals by the pressure transmitter 1 and the flow meter 2, collected by the data collector 3, and the data are transmitted to the control terminal 4 for display processing;

[0040] 2) Collect the output values of the pressure transmitter 1 and the flowmeter 2 at the beginning and end of a pipeline respectively, and send them to the control terminal 4. Let ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com