Temperature control valve for floor heating return water

A valve and water technology, applied in the field of temperature control valves for household control, can solve the problems of high overall investment cost, short circuit of electronic equipment, cumbersome setting steps, etc., achieve good adjustment effect, improve control accuracy, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

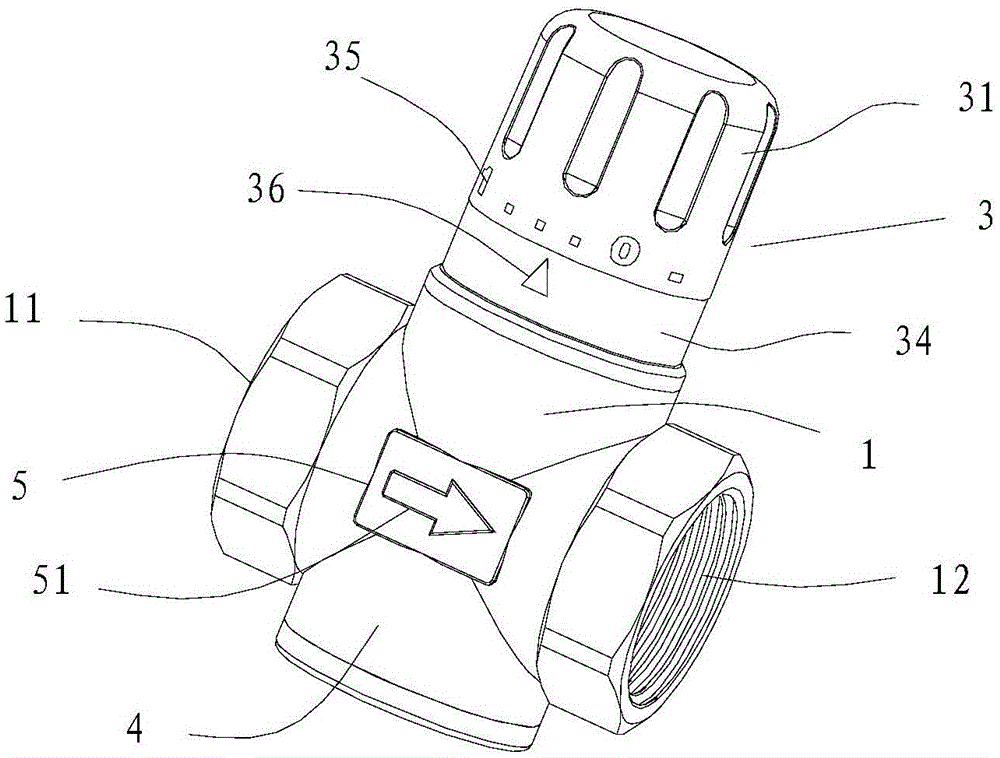

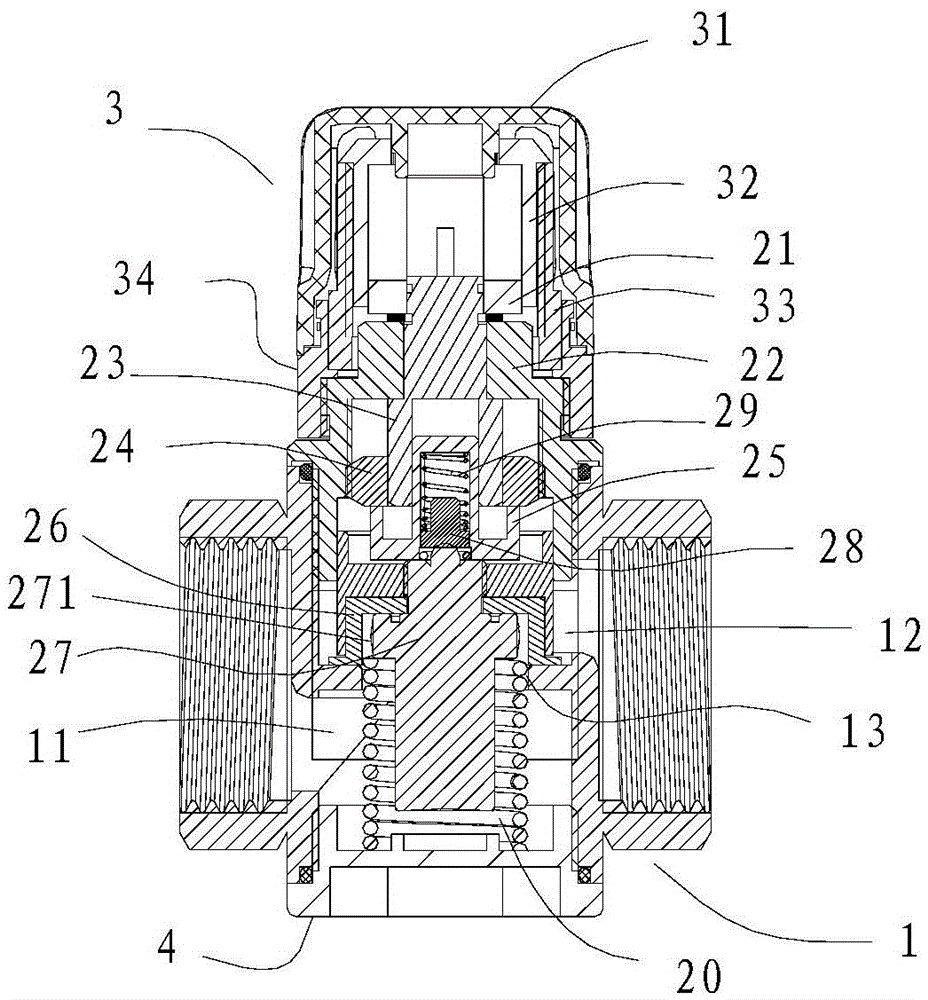

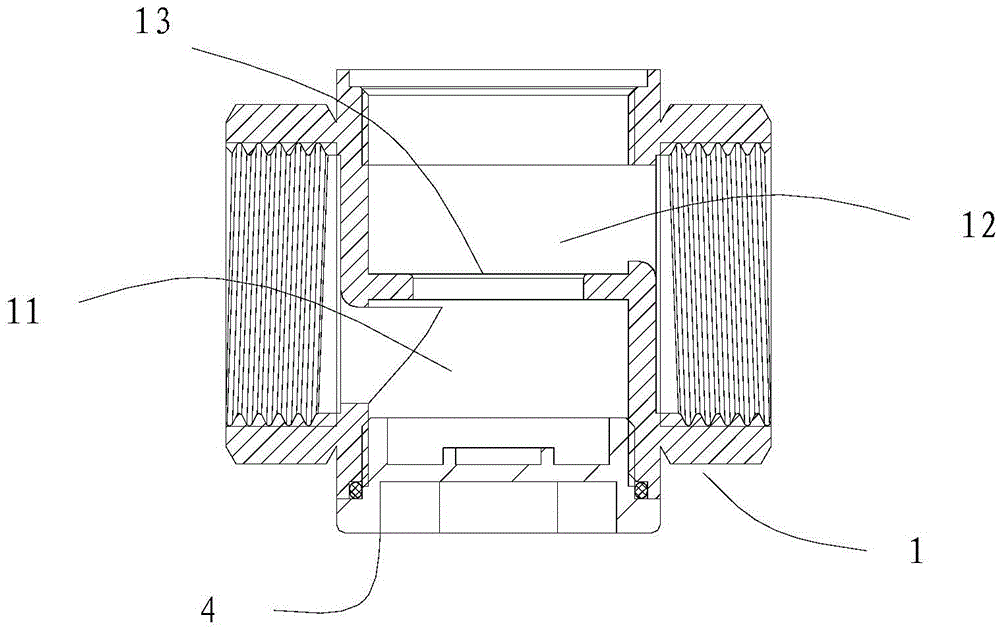

[0021] refer to Figure 1-5 , is a temperature control valve for floor heating and return water, including a valve body 1 with a first flow channel 11 and a second flow channel 12 inside, a temperature control valve core 2 set in the valve body 1, and a temperature adjustment handwheel 3 , sealing cover 4, wherein the valve body 1 is a cross-shaped straight-through structure, and a vertical through hole 13 is provided between the first flow channel 11 and the second flow channel 12 inside it, and the temperature control valve core 2 includes a valve body connected to the valve body 1 The spool cover 22 on the top, the valve stem assembly sleeved in the spool cover 22, the temperature sensing element 27 with a step portion 271 on the outer wall, and the first spring 20, the temperature sensing element 27 is vertically installed in the through hole 13, The stepped portion 271 thereof is located in the second circulation channel 12 above the through hole 13 . The valve stem asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com