Hydrostatic plate bearing

A flow-resistance liquid and composite technology, applied in the direction of bearings, pipes/pipe joints/pipe fittings, shafts and bearings, can solve the problems of high production cost, low rigidity, high working pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical means used to achieve the purpose of the present invention will be described below with reference to the attached drawings, and the embodiments listed in the following drawings are only for auxiliary explanation, so as to facilitate the understanding of your examiners, but the technical means of this case are not limited to Figures listed.

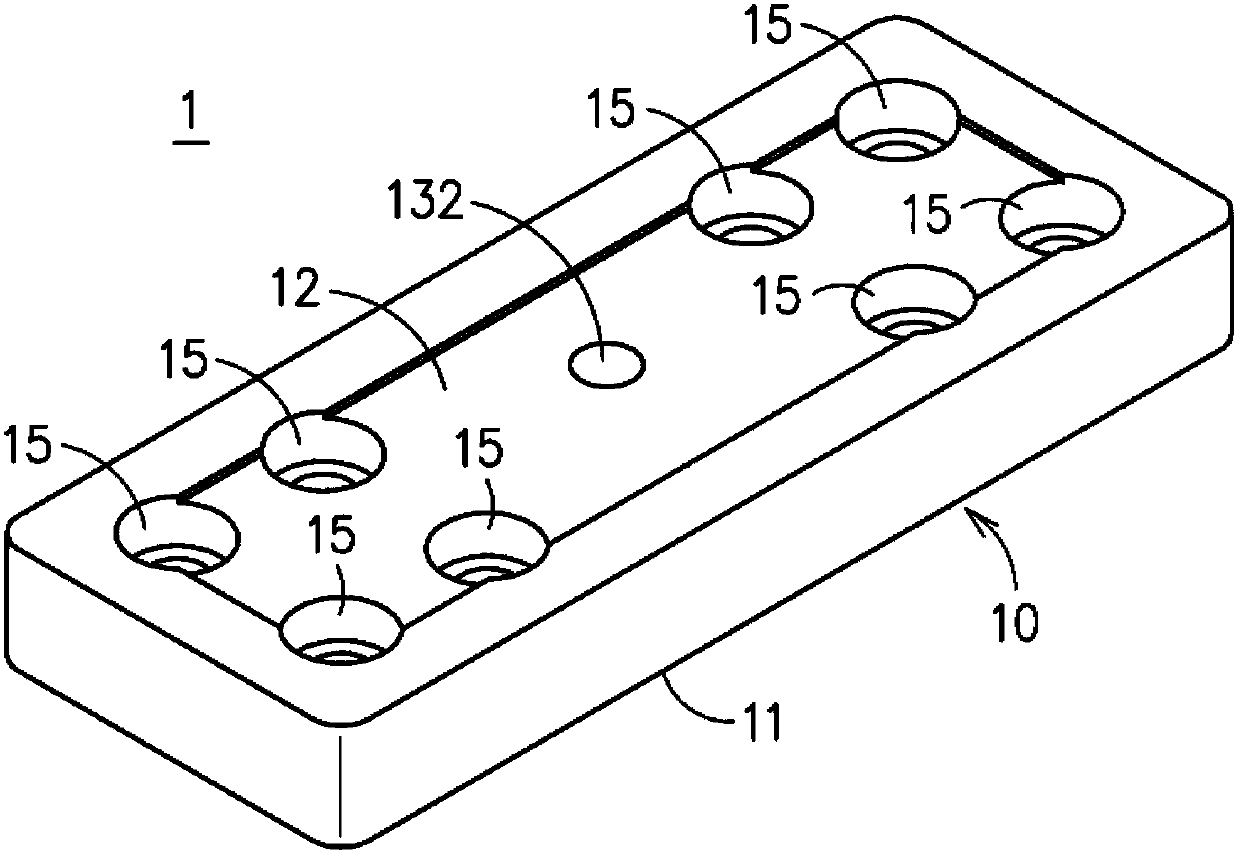

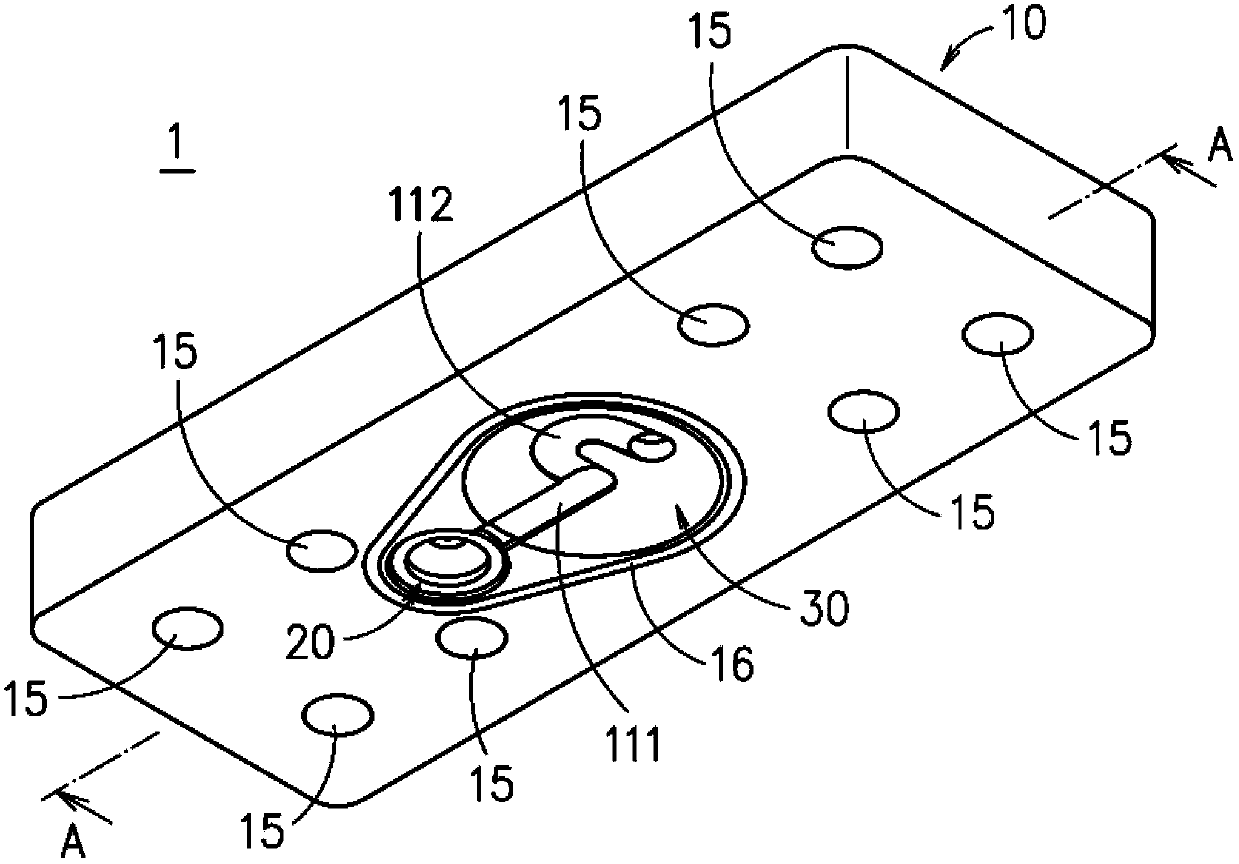

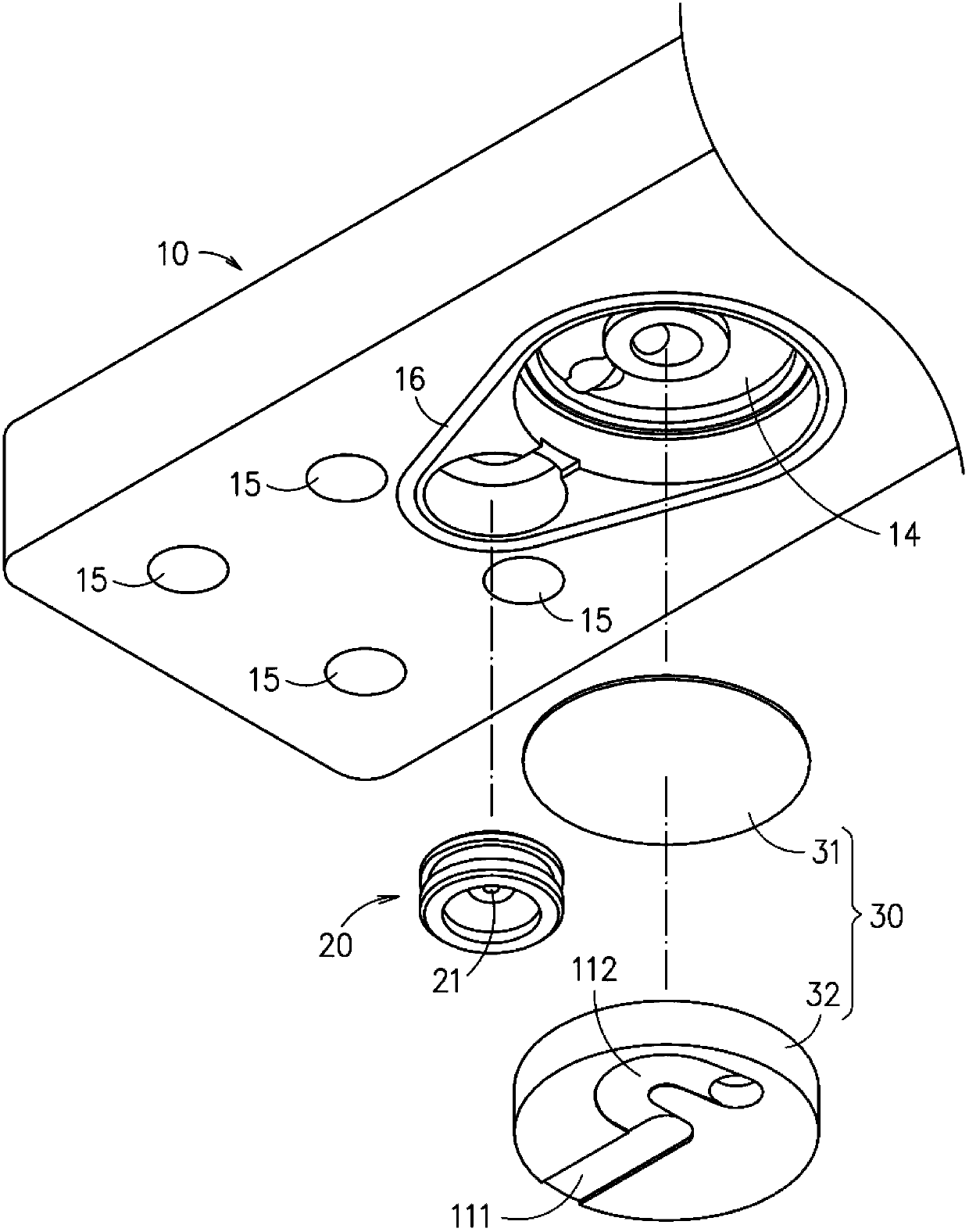

[0049] see Figure 1 to Figure 4 In the shown embodiment, the composite variable flow resistance hydrostatic slider module 1 includes a body 10, and the body 10 has an opposite mounting surface 11 (the bottom surface of the body 10 shown in the figure) and an oil chamber 12 (the body 10 shown in the figure) 10 top). A small hole restrictor 20 and a film restrictor 30 are arranged in the body 10, the small hole restrictor 20 has a first small hole 21, and the film restrictor 30 is composed of a film 31 and a circular block The block body 32 is composed of a second chamber 321 and a second small hole 322. The film 31 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com