Screw bolt fixing mode wheel house installing structure

A technology of fixing method and installation structure, applied in the direction of wheels, wheel cover discs, vehicle parts, etc., can solve the problem of detachment from the wheel, reduce the effect of extrusion stress, improve installation reliability, and prevent flying out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be described in detail below through the examples. It should be understood that the following examples are exemplary only, and can only be used to explain and illustrate the technical solution of the present invention, and cannot be used to explain the technical solutions of the present invention. restrictions.

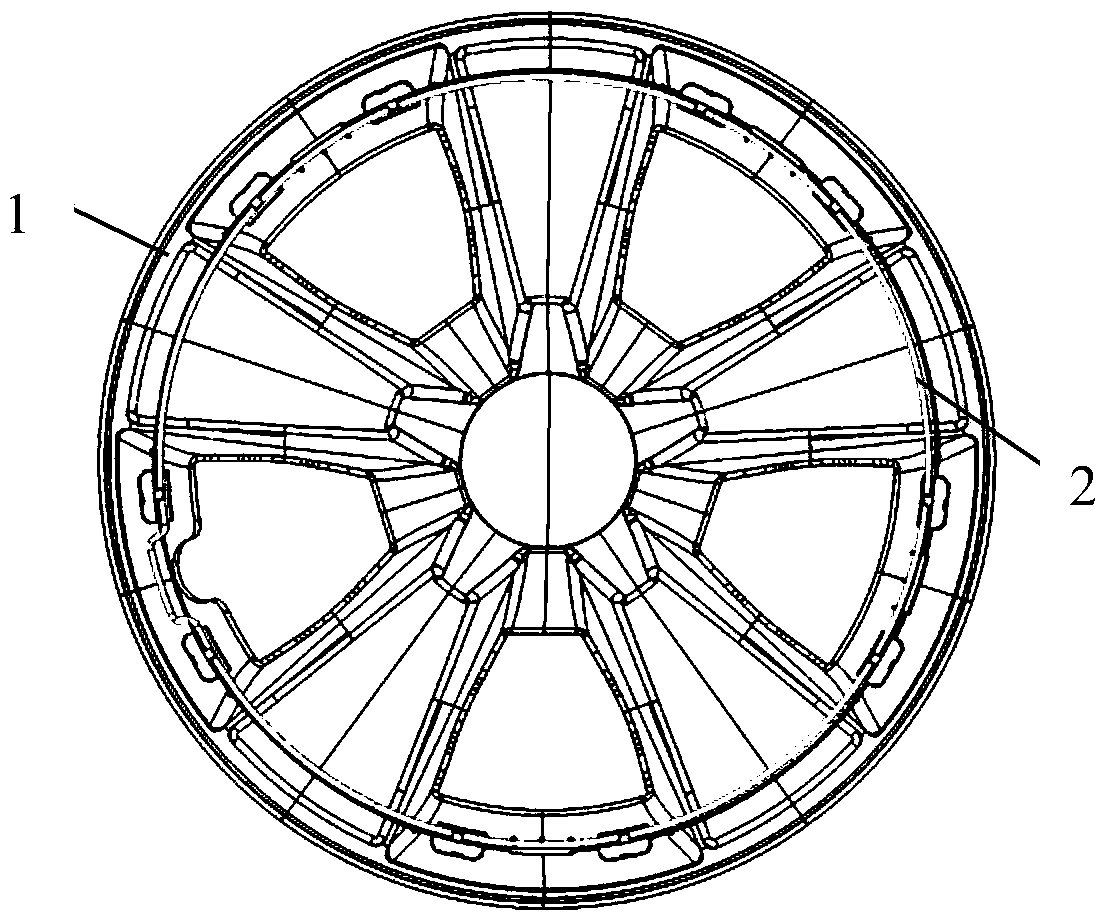

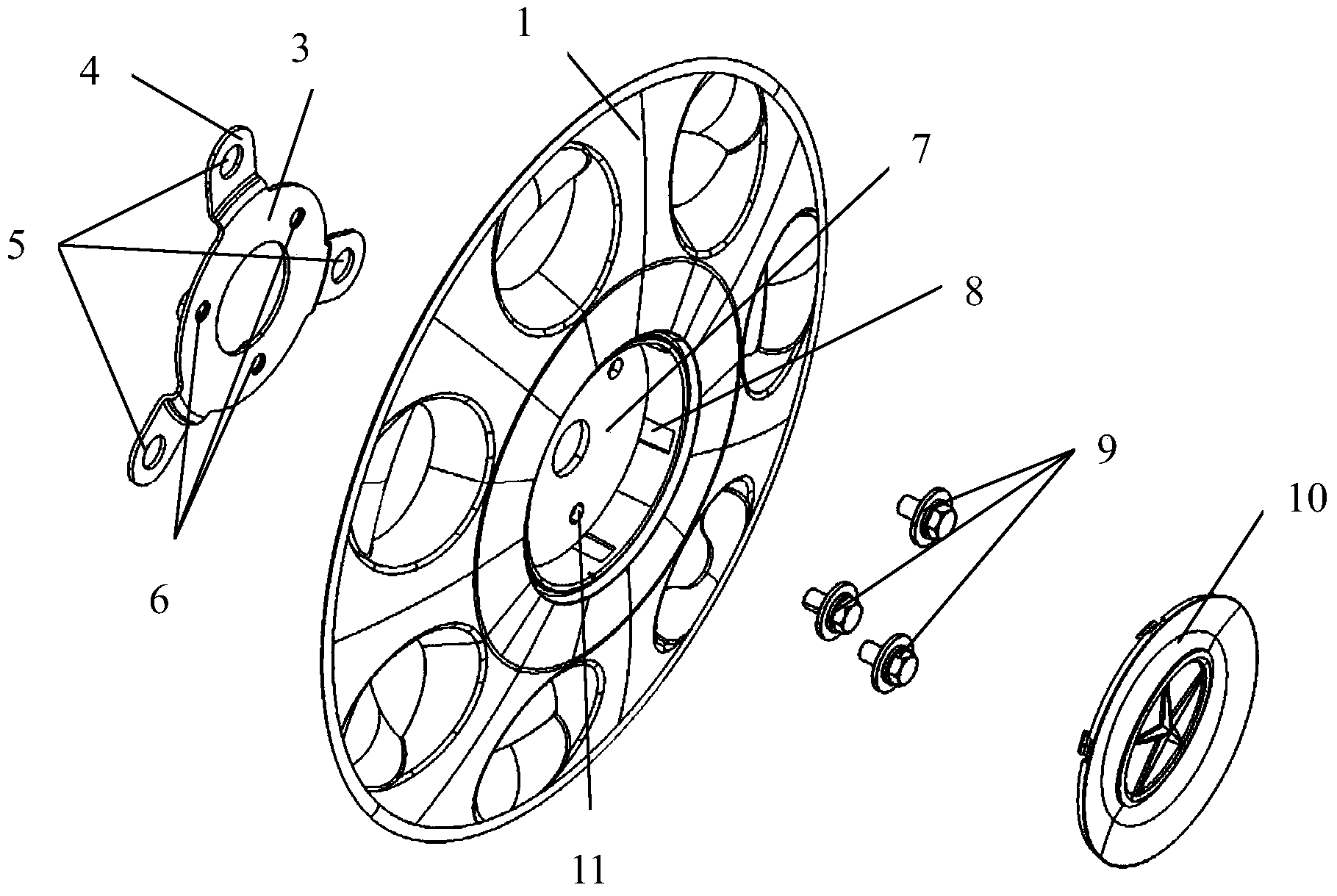

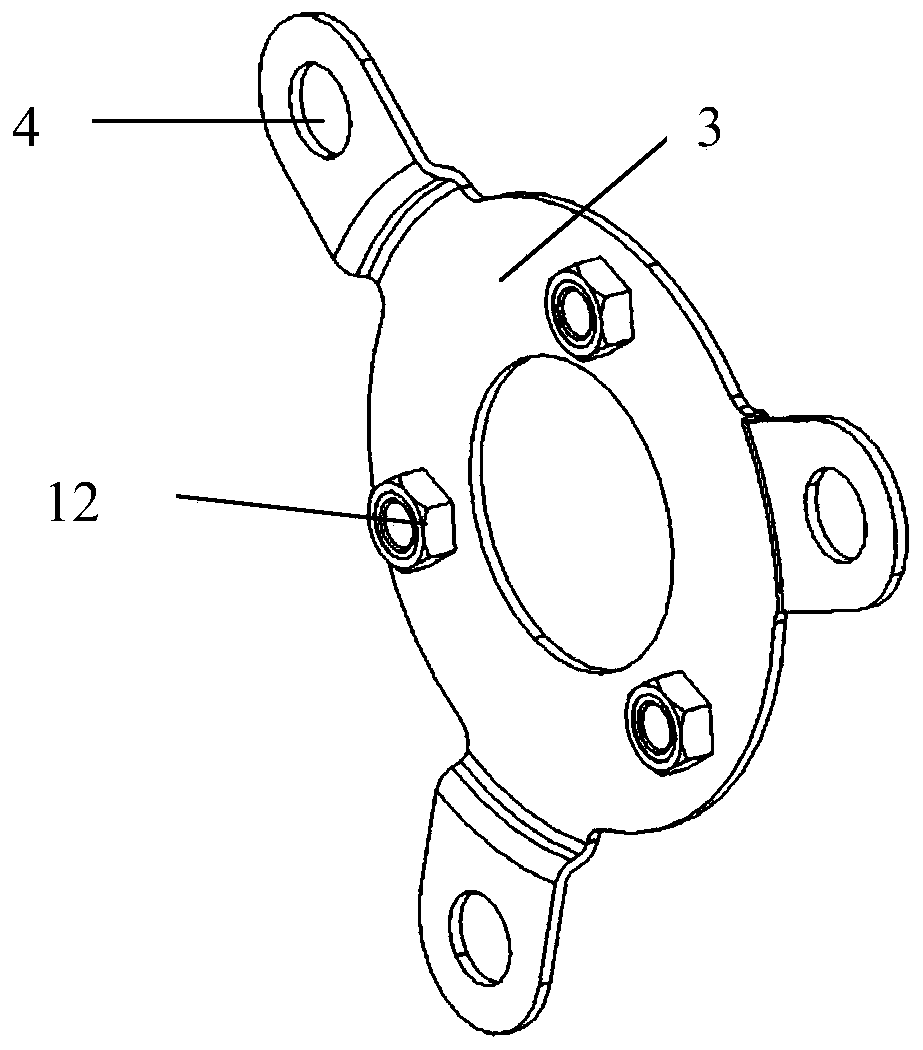

[0022] Such as Figure 2 to Figure 4 As shown, a bolt-fixed wheel cover installation structure includes a wheel cover body 1 , fixing bolts 9 , a wheel cover cover 10 and a transition bracket.

[0023] The central part of the wheel cover body 1 is provided with an embossed structure 7 facing the wheel side, and at least three mounting holes 11 are arranged on the surface of the embossed structure 7; A depression is formed at the position of the depression, and the inner edge of the depression is provided with a slot 8; the inner edge of the wheel cover cover 10 is provided with a claw 13;

[0024] The wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com