Automatic insulator scrubbing device

A technology of insulators and scrubbers, applied in the direction of insulators, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of inconvenient operation, cleaning dead ends, and danger of climbing, and achieve the effect of simple operation and reduced labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

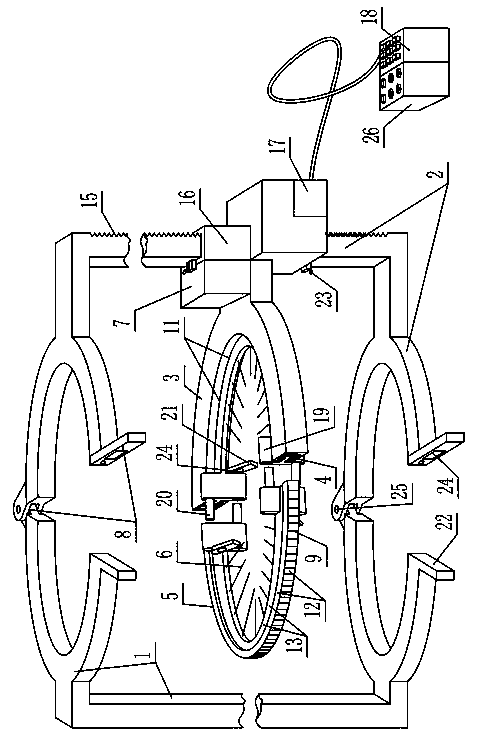

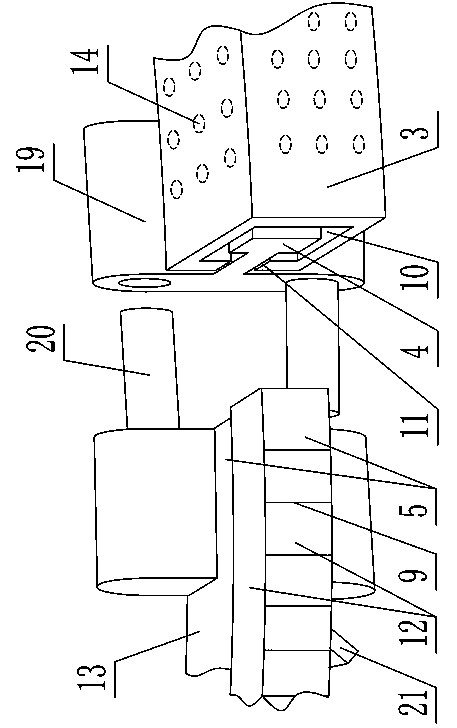

[0025] As shown in the figure, the insulator automatic scrubber includes a left cover 1 and a right cover 2 that cooperate with the outer circumference of the insulator. In this embodiment, the left cover 1 and the right cover 2 adopt a bracket structure, and the board surface can also be used in specific manufacturing. structure or network.

[0026] The corresponding sides of the left cover 1 and the right cover 2 are fixedly connected together through the connecting mechanism 8, and the two ends of the left cover 1 and the right cover 2 are provided with clamping parts that cooperate with the two ends of the insulator, when the left cover 1 and the right cover 2 When connected together by the connecting mechanism, the clamping part is clamped on the two ends of the insulator, and the automatic insulator scrubber is fixed and clamped on the insulator through the clamping part, which is very convenient to install. In this way, it is equivalent to putting an outer cover that is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com