Method for measuring and calculating maximum dry density of natural debris

A technology of maximum dry density and gravel, which is applied in the direction of measuring devices, specific gravity measurement, instruments, etc., can solve the problems that are not conducive to the maximum dry density of natural gravel and are not applicable, so as to reduce the test work and human influence factors, and the distribution of compaction degree The effect of uniformity and dispersion reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

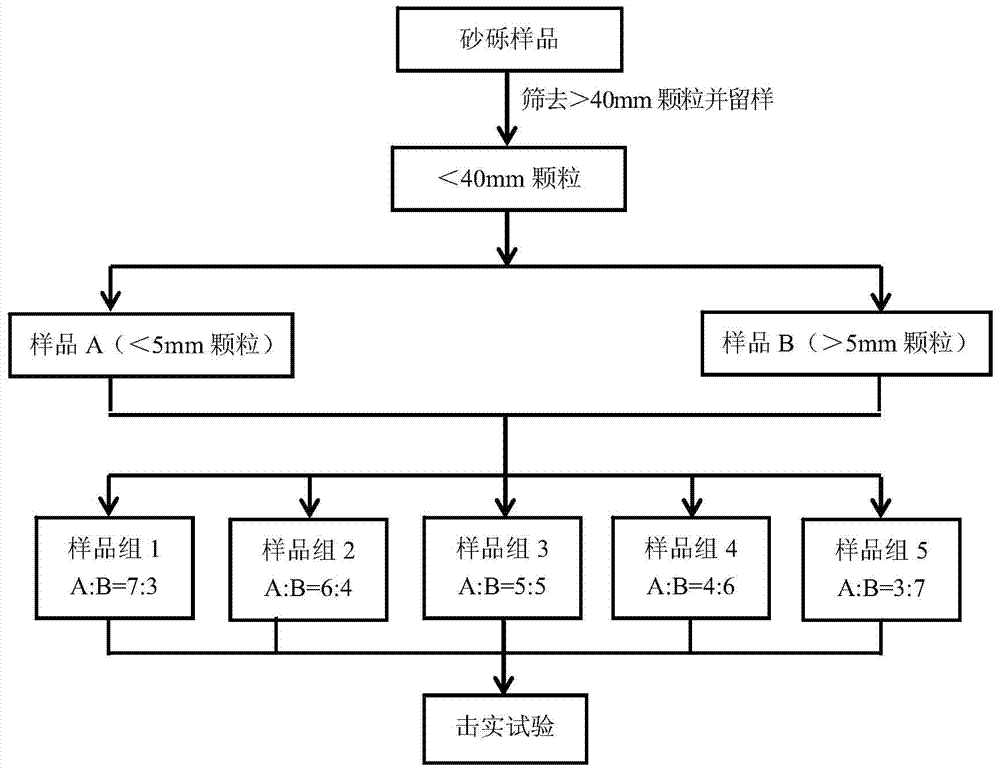

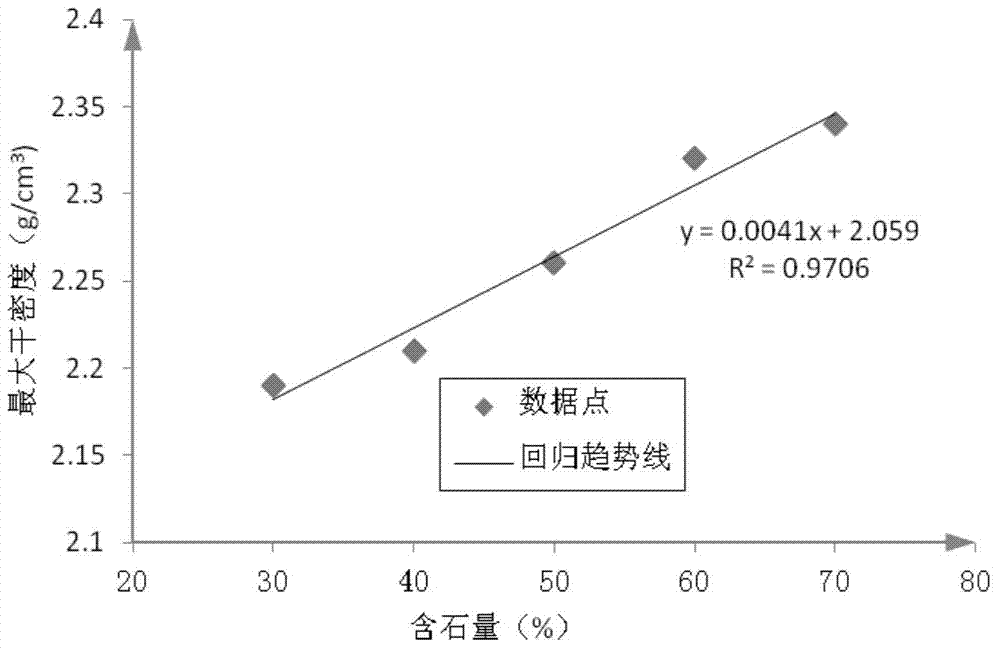

[0052] Embodiment: Following the scheme of the present invention, the present invention will be described by taking the determination of the maximum dry density of natural gravel in a stockyard as an example.

[0053] (1) Estimating the rock content in the stockyard or on-site

[0054] Take 4 groups of representative sand and gravel in different parts of a stockyard, use 5mm and 40mm sieves to sieve each group of sand and gravel respectively, and obtain the stone content of each group of sand and gravel as 42%, 34%, 63% and 51%, respectively. Determine the stone content range of the gravel in the stockyard: 34% to 63%, and get the estimated stone content range of 30 to 70% after this range is ±5%.

[0055] (2) Sample preparation

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com