Pile-up valve type gas-driving liquid booster pump

A technology of integrated valves and booster pumps, which is applied in variable capacity pump components, pumps, piston pumps, etc., can solve the problems of small air flow, low boosting efficiency, and increased cylinder volume, and achieve small pressure fluctuations and increased pressure. The effect of fast pressure speed and large air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

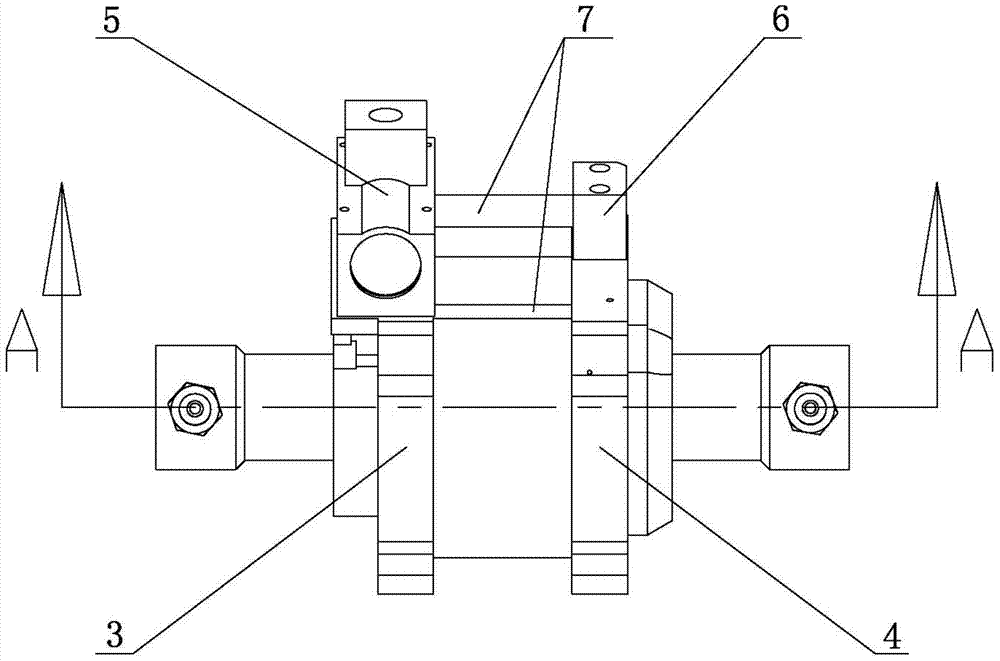

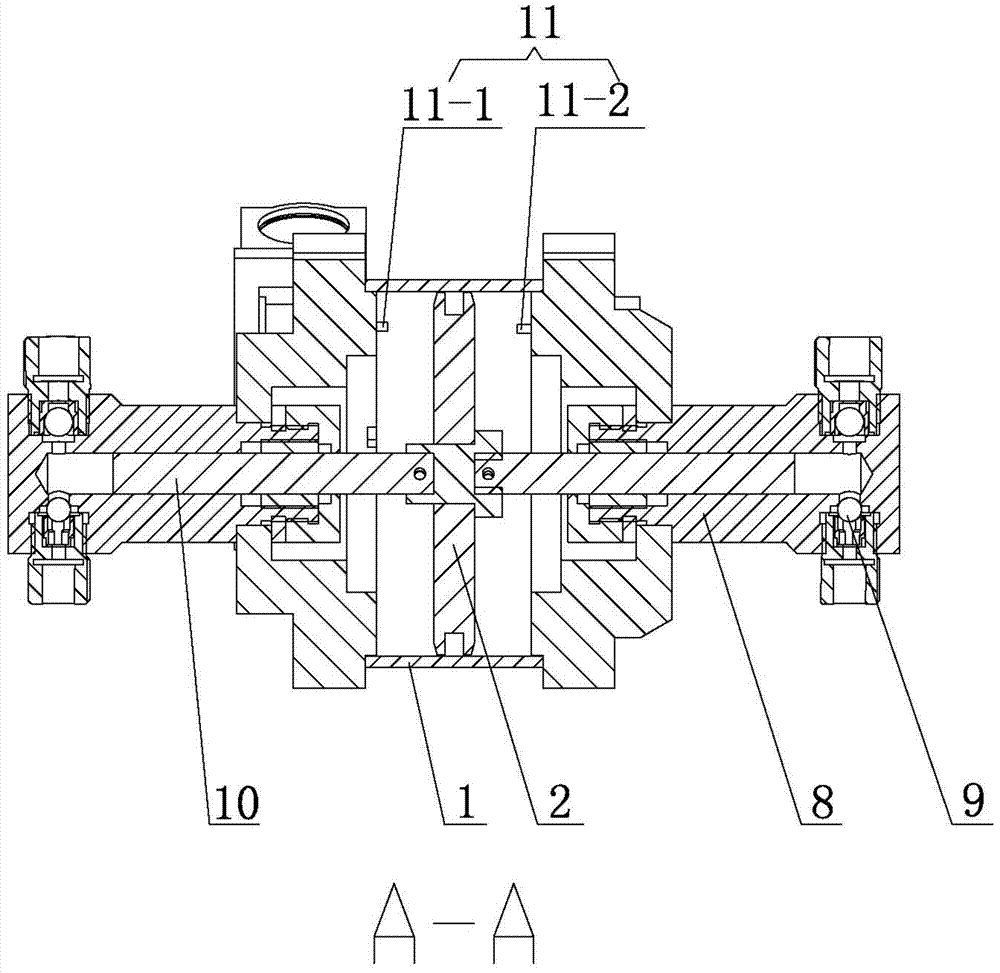

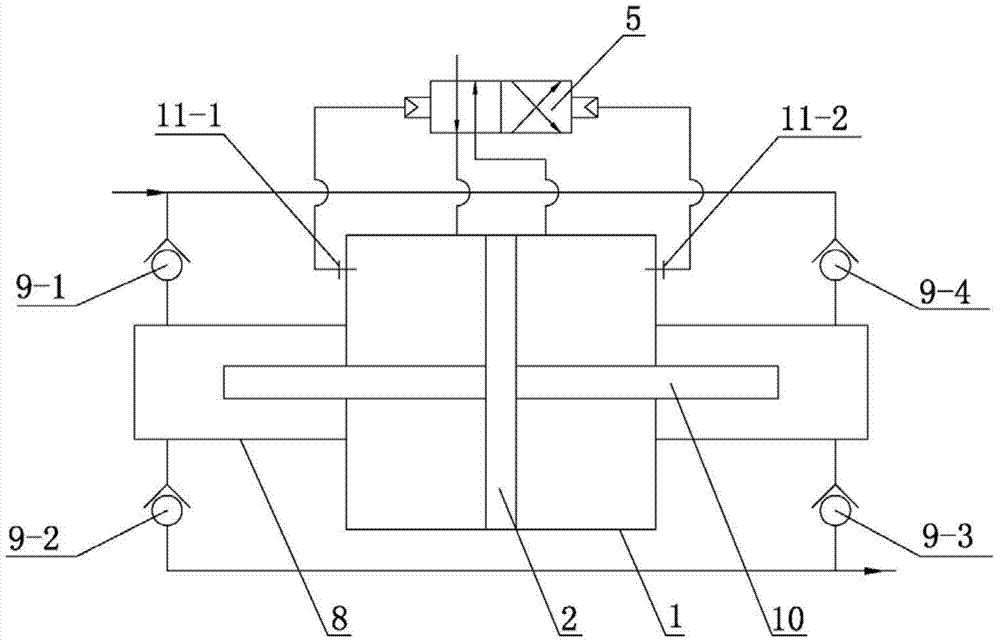

[0031] Please refer to the attached figure 1 to attach Figure 18 As shown, the present invention is an integrated valve type air-driven liquid booster pump, which consists of a low-pressure cylinder 1, a booster piston 2, a front end cover 3, a rear end cover 4, an integrated valve 5, a diverter head 6, and an air guide tube. 7. High-pressure cylinder 8, one-way valve 9, plunger 10 and pilot valve 11 are assembled.

[0032] Wherein, the front end cover 3 and the rear end cover 4 are respectively arranged at both ends of the low-pressure cylinder 1; the booster piston 2 is housed in the low-pressure cylinder 1, and the plunger 10 is respectively installed at both ends thereof. The booster piston 2 divides the low-pressure cylinder 1 into two left and right driving chambers, which are sealed with an O-ring. The plunger 10 is pin-connected with the booster piston 2, and the booster piston 2 drives the plunger 10 to move.

[0033] The integrated valve 5 is installed on the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com