Stope route arrangement mode and method beneficial to roof-contacted filling

A layout method and mining approach technology, applied to fillings, safety devices, mining equipment, etc., can solve problems such as complex construction management, high safety risks, and high technical level requirements, and achieve simple process and construction management, and reduce support The effect of simple cost and recovery process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

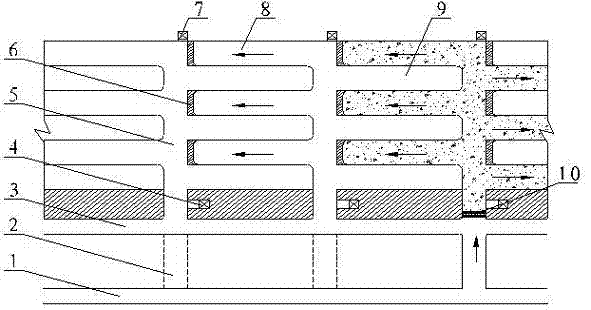

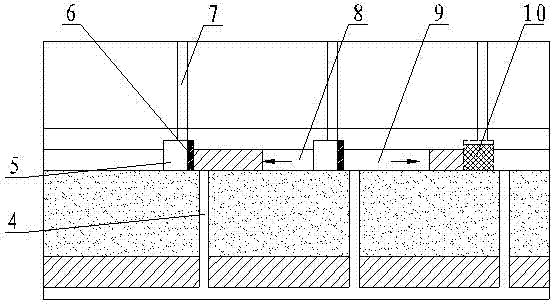

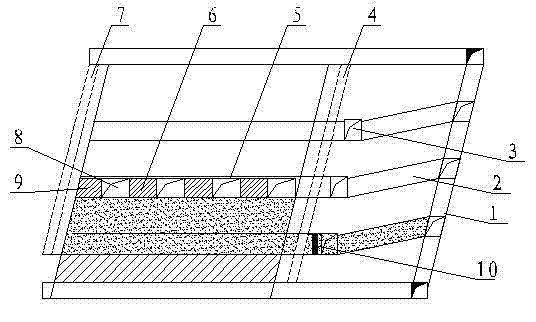

[0028] The construction scheme of the stope approach layout method that is beneficial to filling proposed by the present invention is as follows:

[0029] (1) Stope mining and cutting

[0030] Construct a downward slope connecting road 2 from the middle slope 1 to the footwall of the ore body. After reaching the design layer height of the stope, construct a connecting roadway outside the vein along the ore body at the boundary of the ore body footwall 5 to 8 meters 3. Then construct a central cutting lane 5 perpendicular to the ore body trend at intervals of 16 to 20 meters to the boundary of the ore body hanging wall along the ore body trend, and run through the Shunlu mine shaft 4 located in the ore body footwall and the ore body hanging wall The return air filling well 7. Wherein the Shunlu mine shaft 4 runs through the stope and the mining roadway at the bottom of the stope, and the air return filling shaft 7 runs through the stope and the upper return air filling roadway...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com