Sewing machine pressing mechanism and sewing machine with sewing machine pressing mechanism

A technology of sewing machine and pressing rod, which is applied in the direction of cloth pressing mechanism, sewing machine components, sewing equipment, etc. It can solve the problems of short belt life and easy tendency of sewing materials, etc., achieve stable rotation, prolong service life, and reduce the probability of needle breakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

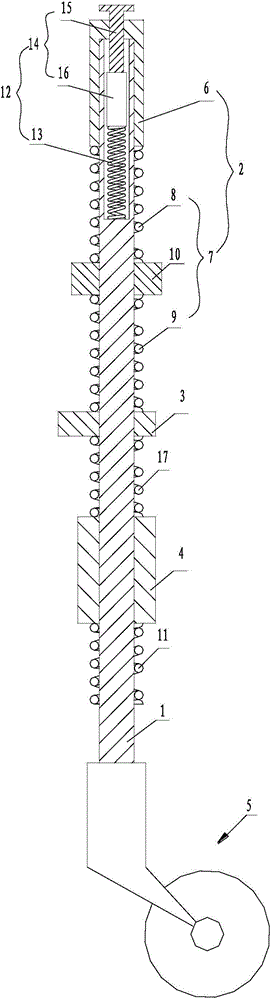

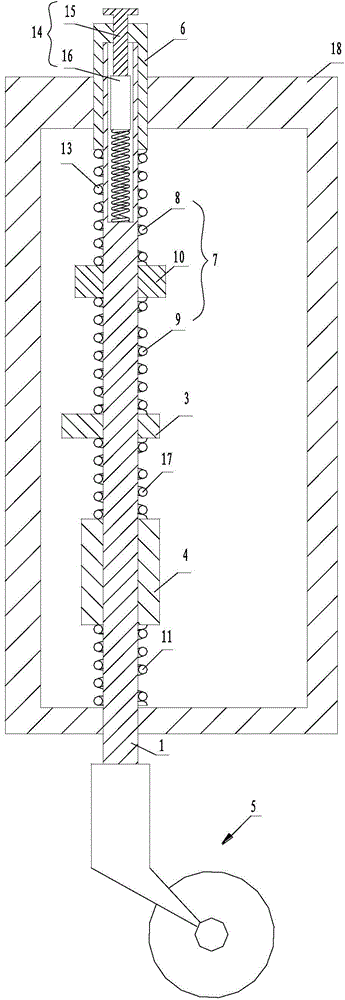

[0028] figure 1 Shown is one embodiment of the pressing mechanism of the sewing machine of the present invention.

[0029] see figure 1 , the pressing mechanism includes a pressing rod 1 , an external pressure regulating assembly 2 , a lifting guide frame 3 , a connecting ring 4 , and a presser foot assembly 5 . The lifting guide frame 3 is fixed on the pressing rod 1 . The connecting ring 4 is located below the lifting guide frame 3 , it is sheathed on the binder rod 1 , and can slide relative to the binder rod 1 in a certain area. The presser foot assembly 5 is fixed on the lower end of the presser rod 1 .

[0030] The external pressure regulating assembly 2 includes an external pressure regulating rod 6 and a first elastic element 7 . A hole 1 is opened at the bottom of the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com