Method for producing citric acid by fermenting soybean molasses

A technology of soybean molasses and citric acid, applied in microorganism-based methods, biochemical equipment and methods, fermentation and other directions, can solve problems such as insufficient utilization of effective ingredients, waste of resources, etc., to improve utilization value and reduce environmental pressure. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

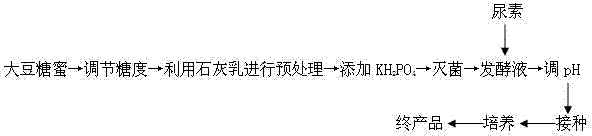

Image

Examples

Embodiment 1

[0018] Embodiment 1: a kind of method for fermenting soybean molasses to produce citric acid comprises the following steps:

[0019] (1) Preparation of medium

[0020] Preparation of strain activation medium: add 50 g of peeled potatoes and 200 mL of distilled water to boil for 30 min, filter, take the filtrate, add 5 g of glucose, 4.5 g of agar, distill water to 250 mL, sterilize at 121°C for 20 min, then pour Put it into a test tube and lay a slant surface to prepare a slant medium for future use.

[0021] Preparation of seed medium: Add 50 mL of 60 g / L soybean molasses solution to a 250 ml Erlenmeyer flask, add 2.5 g of glucose, distill water to 100 mL, sterilize at 121°C for 20 min, and cool for later use.

[0022] Preparation of fermentation medium: adjust the initial sugar content of soybean molasses to 26% (mass concentration), add newly prepared 15% lime milk to adjust the pH to 9.0, heat to boil, filter, and adjust the filtrate to pH 6.0 with sulfuric acid, then add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com