Live pig loading and transportation equipment

An equipment and technology for live pigs, applied in the field of tools for pigs, can solve the problems of labor-intensive, labor-intensive, weight loss, etc., and achieve the effects of reducing transfer time, preventing mixed-pen fights, and alleviating stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

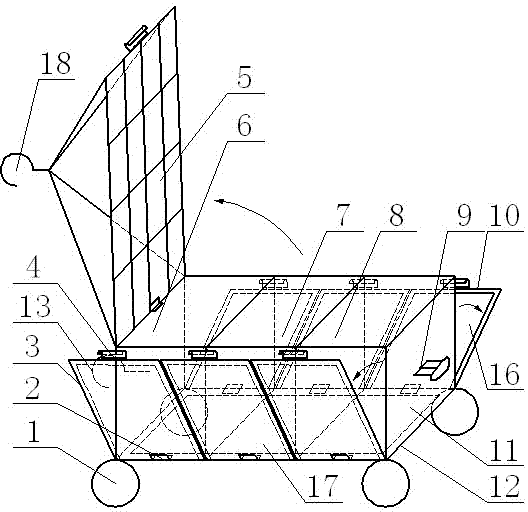

[0017] Attached below figure 1 To attach figure 2 The present invention is described further:

[0018] A kind of pig shipping equipment, comprising a shipping equipment body 7, the shipping equipment body 7 is a rectangular parallelepiped frame, a left plate 6, a right plate 11 and a bottom plate 12 are fixedly arranged on the rectangular parallelepiped frame, and a front plate 12 is flexibly connected to the rectangular parallelepiped frame Plate 3, back plate 10 and top plate 5, the bottom edge of described front plate 3 and back plate 10 is connected flexibly with the bottom frame of described cuboid frame, the left side of described top plate 5 is movable with the top of the left frame of described cuboid frame connection, the right side of the top plate 5 and the top edge of the front plate 3 and the rear plate 10 are at least provided with a lock 4, at least one partition 8 is provided in the rectangular parallelepiped frame, and at least one partition 8 is provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com