Interlamination diastrophism measurement device based on flexible touch screen

A technology of flexible touch screen and interlayer shifting, applied in the direction of measuring devices, instruments, etc., can solve the problems of complex principle, high cost, and difficult implementation, and achieve the effect of low cost, simple structure, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

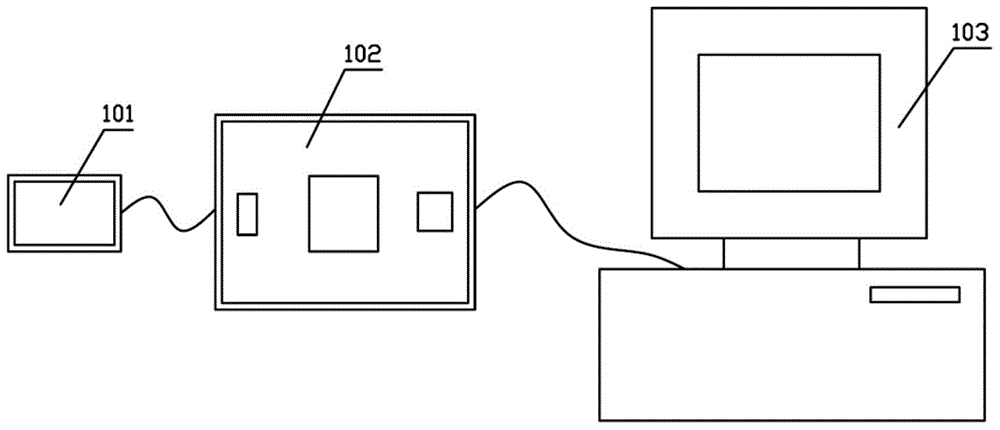

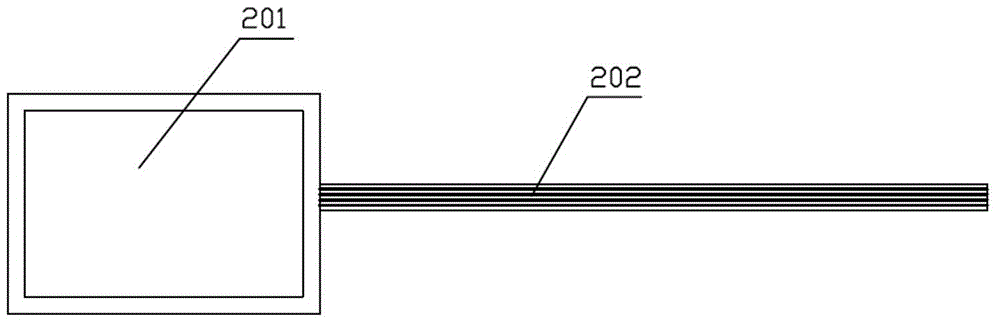

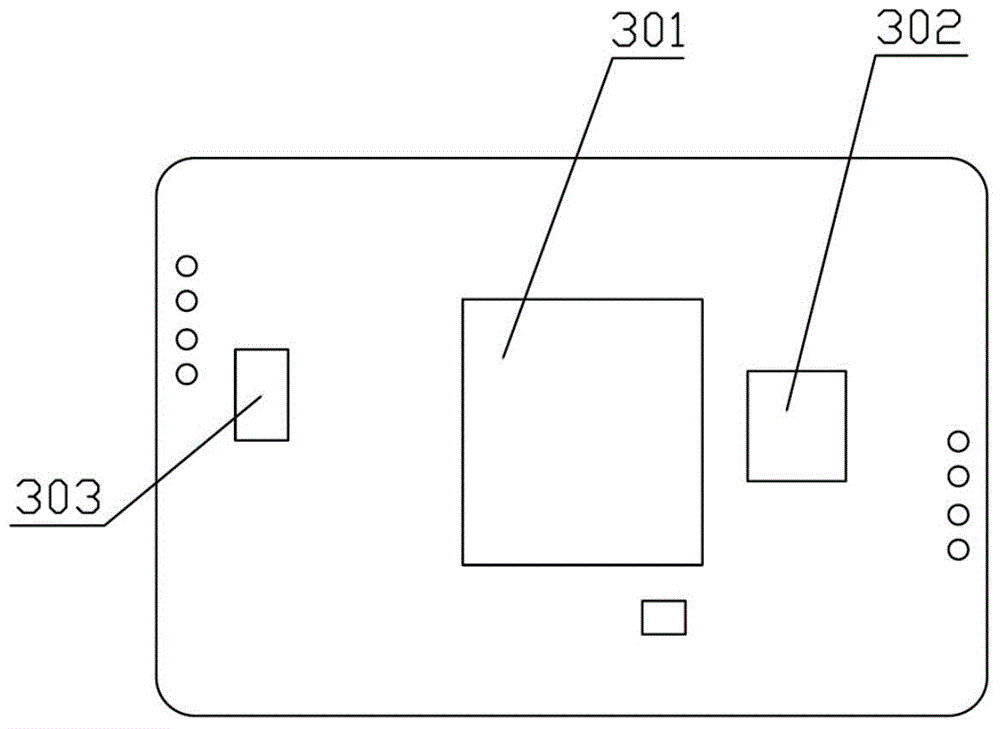

[0018] Such as figure 1 with 2 As shown, the present invention includes a detection probe 401, a flexible touch screen 101, a data processor 102 and a general computer 103, the flexible touch screen 101 is arranged on the upper surface of the first detection part, and the detection probe 401 is arranged on the second detection part The lower surface is bonded to the flexible touch screen 101 , the output end of the flexible touch screen 101 is connected to the input end of the data processor 102 , and the output end of the data processor is connected to the general computer 103 .

[0019] Such as Figure 4 As shown, the detection probe 401 is connected to the second detection part through a fixing device, the fixing device includes a fixing sleeve 403, a spring 404 and a fixing screw 405, the second detection part is provided with a through hole, and the The fixing sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com