Automobile wrapping assembly detection tool and method combining multiple standard positioning system

A positioning system and positioning datum technology, applied in measurement devices, mechanical measurement devices, mechanical counters/curvature measurement, etc., can solve the problem that the inspection results cannot be intuitively wrapped, and achieve the effect of improving effectiveness and data quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solution of the present invention will be described in detail below through the examples. It should be understood that the following examples are exemplary only, and can only be used to explain and illustrate the technical solution of the present invention, and cannot be interpreted as the technical solution of the present invention. limits.

[0050] In this embodiment, the engine cover hemming assembly inspection tool is taken as an example, and it is also applicable to the hemming assemblies such as car doors.

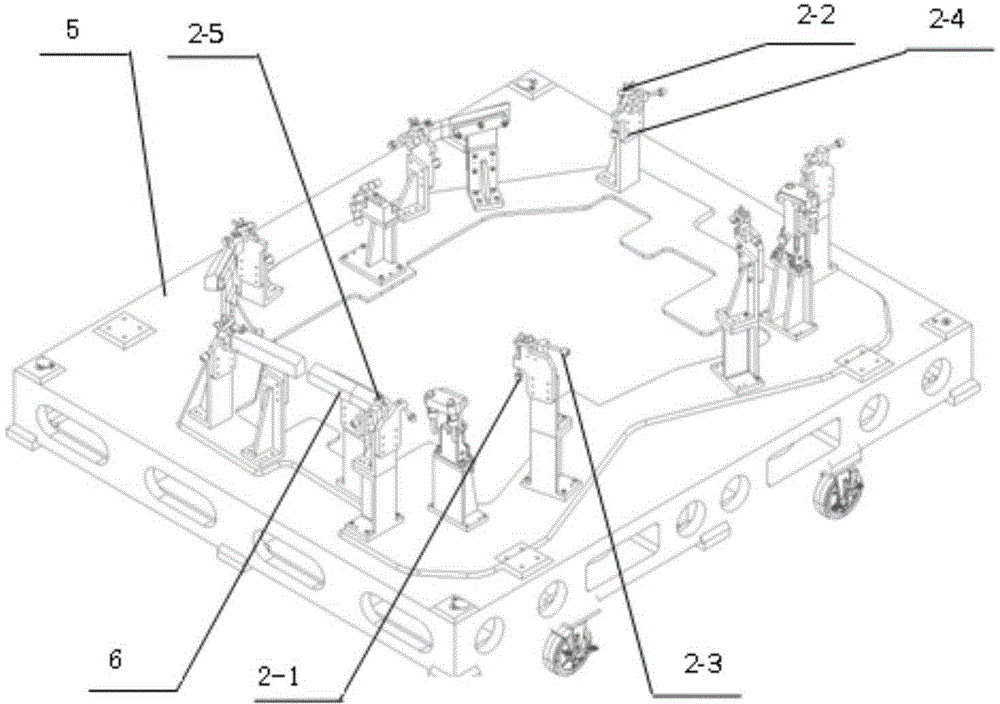

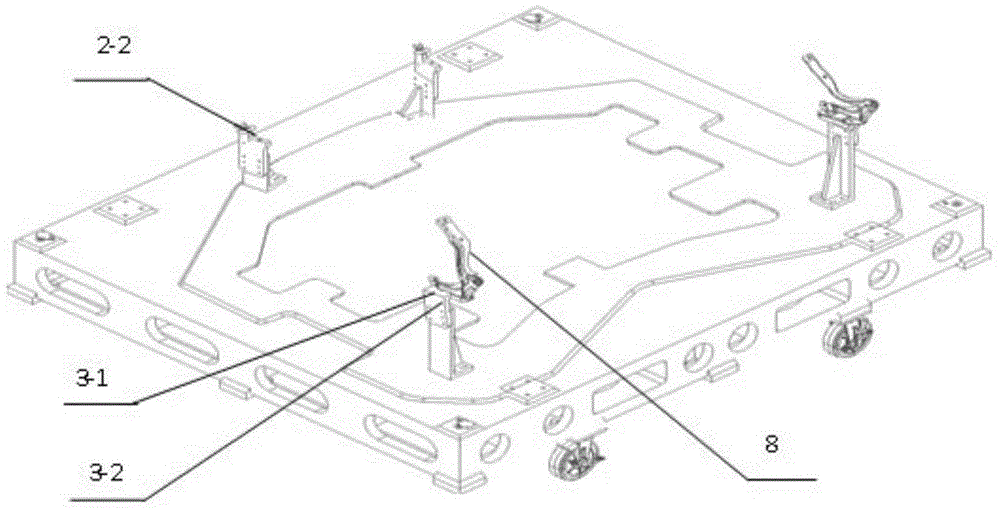

[0051] refer to Figure 1 to Figure 9 As shown, the inspection tool for the engine cover hemming assembly mainly includes the base plate 5, the surface difference and contour detection block assembly 6, the lock detection block assembly 7, the hinge hole detection assembly 4, the inner plate reference positioning system 1, and the outer plate reference positioning System 2, hinge reference positioning system 3; the above-mentioned components 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com