Construction device for precast surface and cast-in-place core filler wall

A construction device and prefabricated surface technology, which is applied in the field of building filling walls, can solve the problems of wall flatness not meeting the requirements, stability and rigidity, uneven tension distribution of force cables, etc., and achieve fast and one-way wall formation Improved flexural rigidity and flexural bearing capacity, easy handling and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Prefabricated components: prefabricated panel 2 (length 3200, width 1200, thickness 20) is attached with glass fiber mesh, and the filling core material is gypsum and cement (according to 3:1). The keys 16 (length, width 100, thickness 180) are mass-produced in the factory assembly line using gypsum materials and then transported to the construction site. The six connecting keys 16 and two prefabricated panels 2 are pasted firmly with adhesive to form a cavity mold. Shape positioning key 1 adopts regenerated duroplastic to mass-produce (square section, length 200, width 80, 180 two kinds, thickness 80) in factory assembly line.

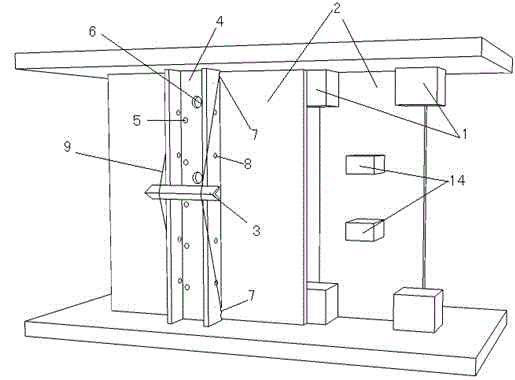

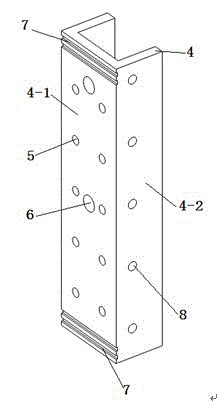

[0050] Construction tools: such as figure 2 with image 3 As shown, the pressure plate 4 is made of plastic steel (groove section: the bottom plate 4-1 is 250 wide, the side plate 4-2 is 150 high, the plate thickness is 10, and the length is 3200). , connecting holes 5 with a spacing of 500, watering holes 6 with a diameter of 50 are provide...

Embodiment 2

[0056] Such as Image 6 As shown, different from Embodiment 1, the prefabricated plate 2 of this example adopts a 10-thick thin plate. Because the plate is thin, for this reason, a drag cable 9 is arranged between the pressure plates 4 at intervals of about 500 cm. Long adjustable structure, the two ends of the cable 9 are passed through the anchor hole 8 of the pressure plate 4 and pinned with wooden bolts, and then the locking keys 14 and the opening keys 13 are alternately arranged between the two strands of the cable 9 to make it shape diamond-shaped, such as Figure 13 with Figure 14 , the locking key 14 adopts a grooved plastic steel clip (length 30, width 30, height 15, wall thickness 5), and the opening key 13 adopts a plastic steel channel plate (length 200, width 50, height 20, wall thickness 5), both ends There are card slots with a width of 10. Two force-applying keys 11 are set between the locking key 14 of the cable 9 and the prefabricated panel 2, and ...

Embodiment 3

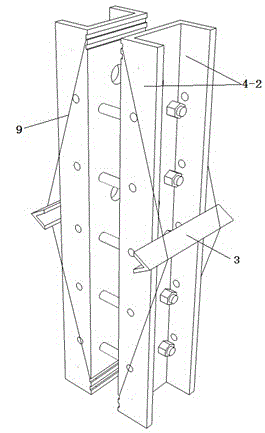

[0058] Such as Figure 9 As shown, different from Embodiment 1, the prefabricated plate 2 of this example adopts a 10-thick thin plate. Because the plate is thin, for this reason, a self-balancing stiffener 10 is arranged between the pressure plates 4 at intervals of about 500, and the stiffener 10 I-shaped cross-section plastic steel (length 1200, width 50, height 150, wall thickness 5) is used, and the lower sides of both ends are provided with 200 long serrated grooves (groove depth 10, width 20). Long adjustable structure. The two ends of the stiffener 10 are fixed on the side plate 4-2 of the pressure plate 4, the ring cable 9 is stuck in the sawtooth concave-convex slot 7 at the two ends of the stiffener 10, and the two balance keys 3 are used to pin the cable 9 to the stiffener 10 At one-third and two-thirds of the top surface, make the bending of the cable 9 and the stiffener 10 form a trapezoid, and then move the end of the cable 9 outward to the outer concave-convex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com