A kind of disazo compound and composite black dye comprising the compound

A technology of black dyes and compounds, applied in the field of composite black dyes, which can solve the problems that the characteristics cannot meet the required requirements, and achieve the effects of high affinity, good linear co-planarity, and long conjugated systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

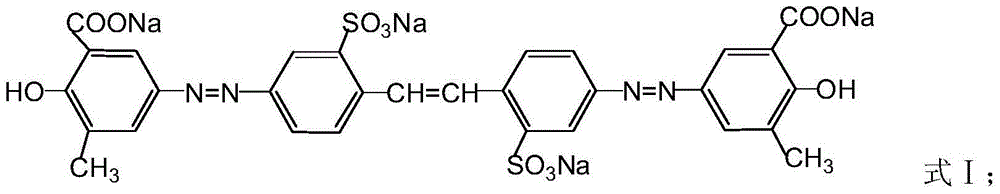

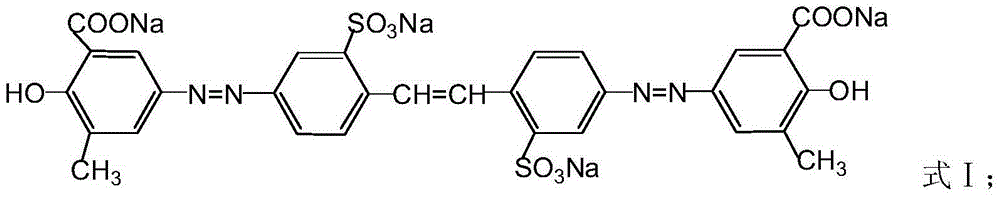

[0026] Example 1 Preparation of disazo compounds with formula I and formula II structures

[0027] Add 370 parts by weight of DSD acid to an appropriate amount of water for beating for 1 hour, add ice and cool down to 5°C and stir for 30 minutes, then add 240 parts by weight of hydrochloric acid with a mass fraction of 30% and continue stirring for 30 minutes until a uniform acid mixture is obtained. After making 140 parts by weight of sodium nitrite into an aqueous solution with a mass fraction of 30%, add it to the acid mixture of DSD acid and hydrochloric acid for about 60 minutes (after obtaining the acid mixture) for diazotization reaction, and maintain the temperature at 5-10°C , the pH value was 1.2~1.5 and reacted for 2 hours. After the reaction, use sulfamic acid to eliminate excess sodium nitrite to obtain diazonium salt, then add 304 parts by weight of 2-hydroxyl-3-methylbenzoic acid, and maintain the temperature at 5~8 React for 4 hours at ℃ until the 2-hydroxy-3-m...

Embodiment 2

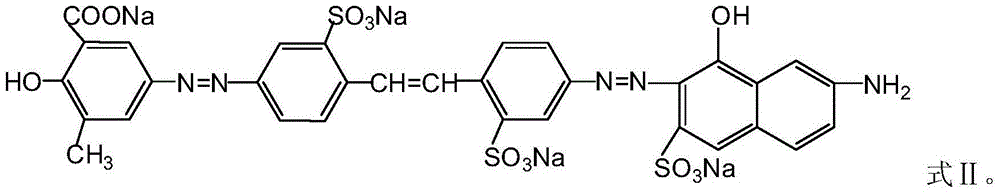

[0031] The preparation of embodiment 2 composite black dyes

[0032] Add 565 parts by weight of 4-ethyl sulfate sulfonyl aniline to an appropriate amount of water to make a slurry for 1 hour, add ice to cool down to 8°C and stir for 30 minutes, maintain the temperature at 8°C, add 240 parts by weight of hydrochloric acid with a mass fraction of 30% and continue stirring for 30 minutes , After 140 parts by weight of sodium nitrite was made into an aqueous solution with a mass fraction of 30%, it was added to a mixture of 4-ethyl sulfate sulfone aniline and hydrochloric acid within 30 minutes for diazotization reaction. Maintain the temperature at 5-8°C, pH value 1.0-1.2 and react for 1.5 hours, then use sulfamic acid to eliminate excess sodium nitrite. After eliminating excess sodium nitrite, add 341 parts by weight of 1-amino-8-naphthol-3.6-disulfonic acid monosodium salt to the diazonium salt, maintain the temperature at 0-5°C for 5 hours, and adjust the pH with baking soda p...

Embodiment 3

[0036] The composite black dye of the present invention can be obtained by fully mechanically mixing 30 parts by weight of the compound of formula I of the present invention, 10 parts by weight of the compound of formula II of the present invention and 60 parts by weight of the compound of formula III of Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com