Preparation method of titanium alloy surface growth factor composite coating

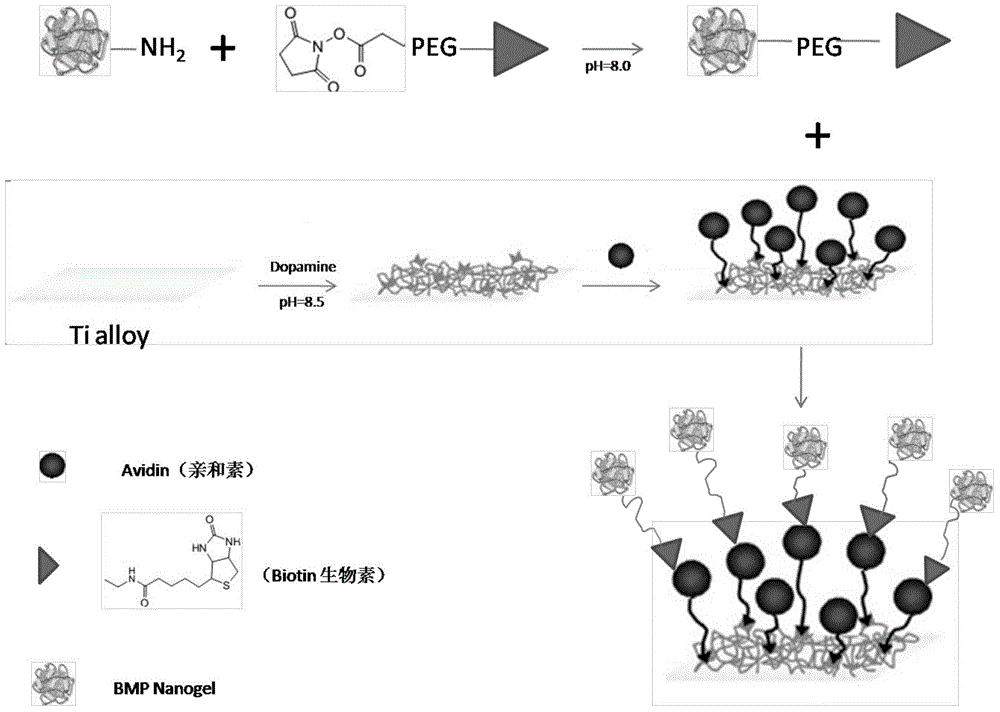

A growth factor and composite coating technology, applied in medical science, prostheses, etc., can solve the problems of direct immobilization of growth factor Nanogel, and achieve good activity retention, mild reaction conditions, and simple reaction operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] a. Dissolve dopamine in 20mM PBS solution with pH=7.4 to prepare a dopamine solution with a concentration of 1mg / ml, flush the above solution with nitrogen flow for 1h; 1-6mol / LN a Soak in OH for 30min, then wash with ultrapure water until the eluent is neutral; vacuum-dry the obtained Ti sheet; add the treated titanium sheet to the above dopamine solution, and then add 1mg of ammonium persulfate (APS) , reacted at 30°C for 2h;

[0024] b. Wash the titanium sheet obtained in a with ultrapure water, then soak it in 1mg / ml aqueous solution of avidin, and react at 20°C for 1h;

[0025] c. Dissolve the growth factor nanogel in 50mM boric acid buffer solution with pH=8.0 to prepare a 0.1mg / ml solution, take 1ml of the above solution and add 1ul10mg / ml Biotin-PEG-NHS solution, and magnetically stir for 2h;

[0026] d. Wash the titanium sheet obtained from the treatment in b with ultrapure water, and dry naturally under nitrogen flow. Take 10ul of the solution obtained in c...

Embodiment 2

[0029] a. Dissolve dopamine in 20mM PBS solution with pH=7.4 to prepare a dopamine solution with a concentration of 2mg / ml, flush the above solution with nitrogen flow for 2h; 3mol / L N a Soak in OH for 40min, then wash with ultrapure water until the eluent is neutral; vacuum-dry the obtained Ti sheet; add the treated titanium sheet to the above dopamine solution, and then add 2mg of ammonium persulfate (APS) , reacted at 40°C for 4h;

[0030] b. Wash the titanium sheet obtained in a with ultrapure water, then soak it in 2mg / ml aqueous solution of avidin, and react at 30°C for 12h;

[0031] c. Dissolve the growth factor nanogel in 50mM boric acid buffer solution with pH=8.0 to prepare a 0.5mg / ml solution, take 1ml of the above solution and add 5ul10mg / ml Biotin-PEG-NHS solution, magnetic stirring for 4h;

[0032] d. Wash the titanium sheet obtained from the treatment in b with ultrapure water, and dry naturally under nitrogen flow. Take 50ul of the solution obtained in c and...

Embodiment 3

[0035] a. Dissolve dopamine in 20mM PBS solution with pH=7.4 to prepare a dopamine solution with a concentration of 4mg / ml, and pour the above solution into a nitrogen flow for 4h; polish the surface of the Ti sheet, and then wash it in n-hexane and 6mol / L N a Soak in OH for 60min, then wash with ultrapure water until the eluent is neutral; vacuum-dry the obtained Ti sheet; add the treated titanium sheet to the above dopamine solution, and then add 4mg of ammonium persulfate (APS) , 30-60°C for 6 hours;

[0036]b. Wash the titanium sheet obtained in a with ultrapure water, then soak it in 4mg / ml aqueous solution of avidin, and react at 40°C for 24h;

[0037] c. Dissolve the growth factor nanogel in 50mM boric acid buffer solution with pH=8.0 to prepare a 1mg / ml solution, take 1ml of the above solution and add 10ul10mg / ml Biotin-PEG-NHS solution, and magnetically stir for 6h;

[0038] d. Wash the titanium sheet obtained from the treatment in b with ultrapure water, and dry na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com