Doubly salient double squirrel cage outer rotor structure of stator permanent magnet dual-rotor motor

A dual-rotor motor and outer rotor technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, electrical components, etc., can solve the problem of large rotor loss, reduce rotor loss, improve stiffness and strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

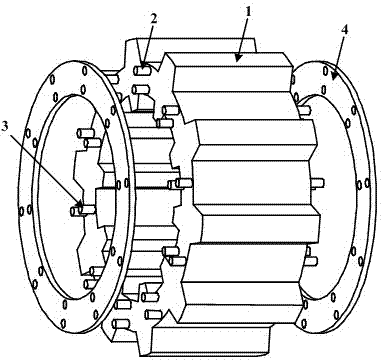

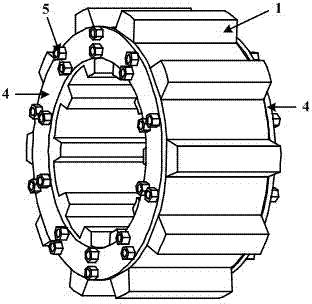

[0010] The double salient pole double squirrel cage outer rotor structure proposed by the present invention is as follows: figure 1 As shown, it consists of an outer rotor body 1, an outer cage bar 2, an inner cage bar 3, and an end ring 4.

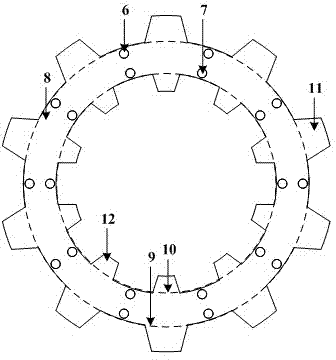

[0011] The structure of the outer rotor body 1 is as follows image 3 As shown, it is in the shape of a cylinder, with an inner and outer double salient pole structure, and is formed by laminating silicon steel laminations 8 . The outer rotor body 1 is punched with two groups of slots, which are the outer slot group 6 and the inner slot group 7 respectively, and the two groups of slots are composed of a plurality of through holes uniformly distributed along the circumferential direction. The through holes of the outer slot group 6 are close to the outer circumference 9 of the yoke of the outer salient pole 11 in the radial direction, and are located in the tangential middle position of two adjacent salient poles on the outer salient pole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com