Angle valve and water outlet method thereof

A technology for angle valves and spouts, applied in lift valves, slide valves, valve details, etc., can solve problems such as water leakage, labor, and complex structures, and achieve the effects of adjustable water outlet angle, simple structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

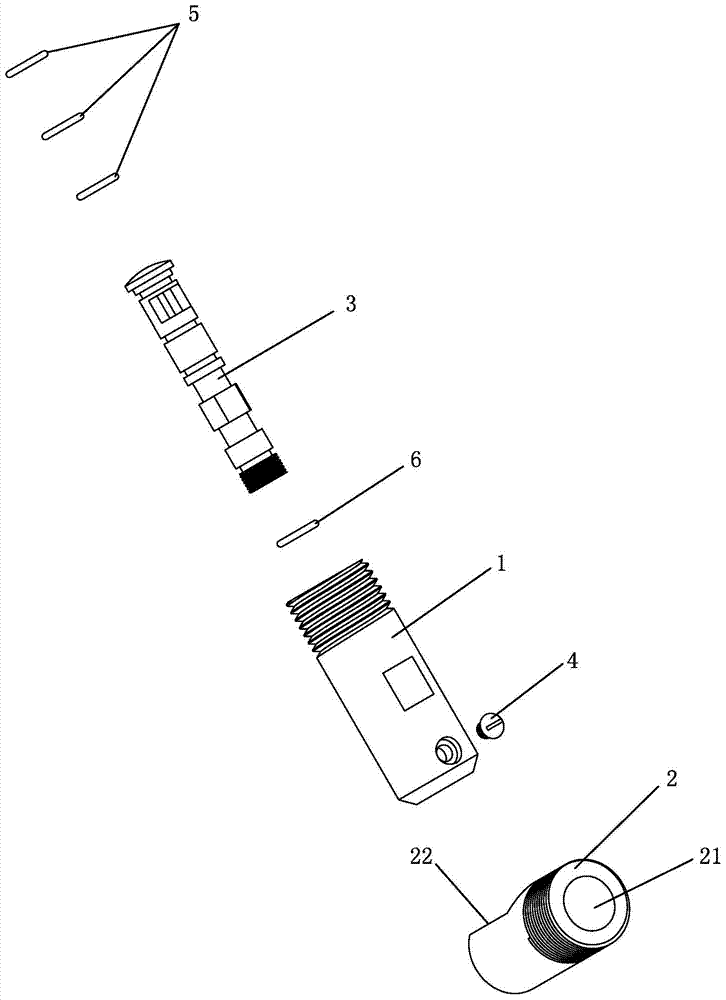

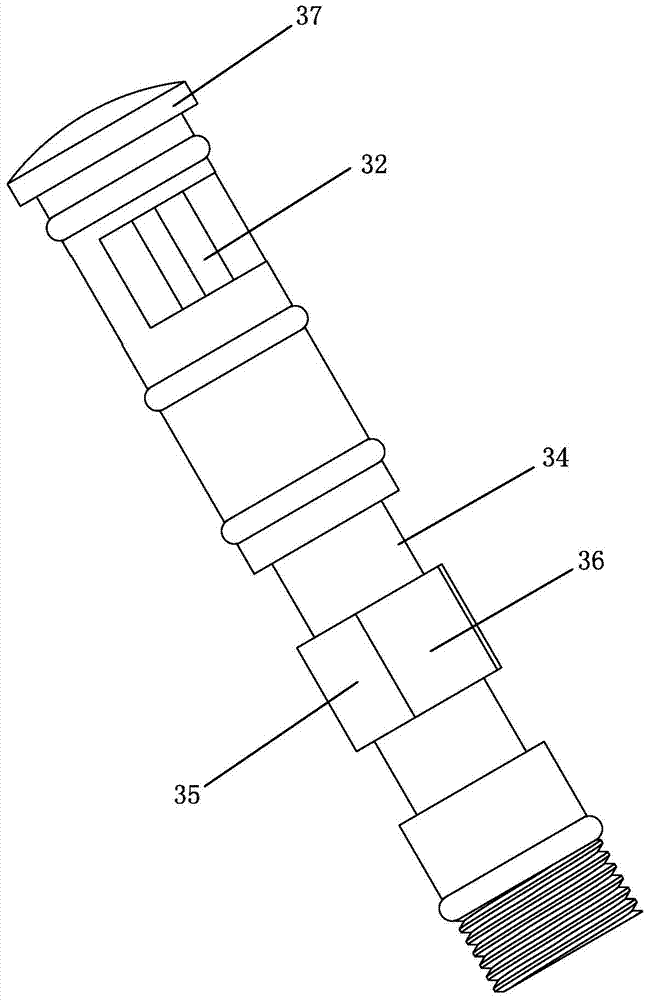

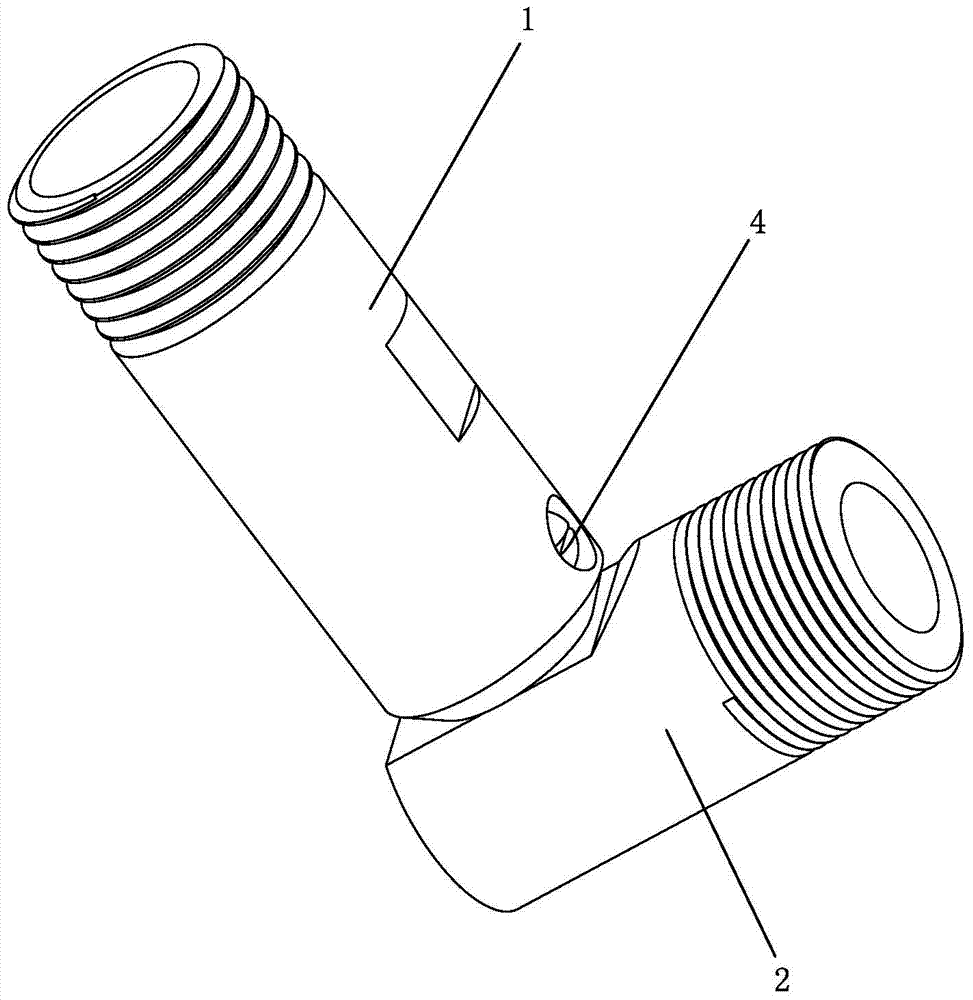

[0024] Embodiment, please refer to the accompanying drawings, an angle valve of the present invention includes a valve body and a pull rod 3, the valve body has a hollow chamber, one end of the valve body is a water inlet 11, and the side is provided with a water outlet 21. The inside of the lifting rod 3 is provided with a water passage 31 along its axial direction, and the water passage 31 has at least one opening for passing water. The water passage hole 32 (specifically, the two water passage holes 32 are on the same ring surface); the lifting rod 3 is sealed and installed in the chamber of the valve body, and the water passage hole 32 is connected with the water inlet of the valve body through axial movement. One of the end and the outlet end is connected or blocked.

[0025] Specifically, the above-mentioned valve body includes a valve casing 1 with a water inlet chamber and a water outlet 2 with a water outlet chamber. The outer surface of one end of the water outlet 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com