A homopolar single-ring hybrid magnetic bearing

A hybrid magnetic bearing and single-ring technology, applied in the directions of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of inconvenient installation and use in space, unreasonable structure of hybrid magnetic bearings, installation and wiring occupying space, etc. Wide range of engineering applications, simple maintenance and calibration, no space required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

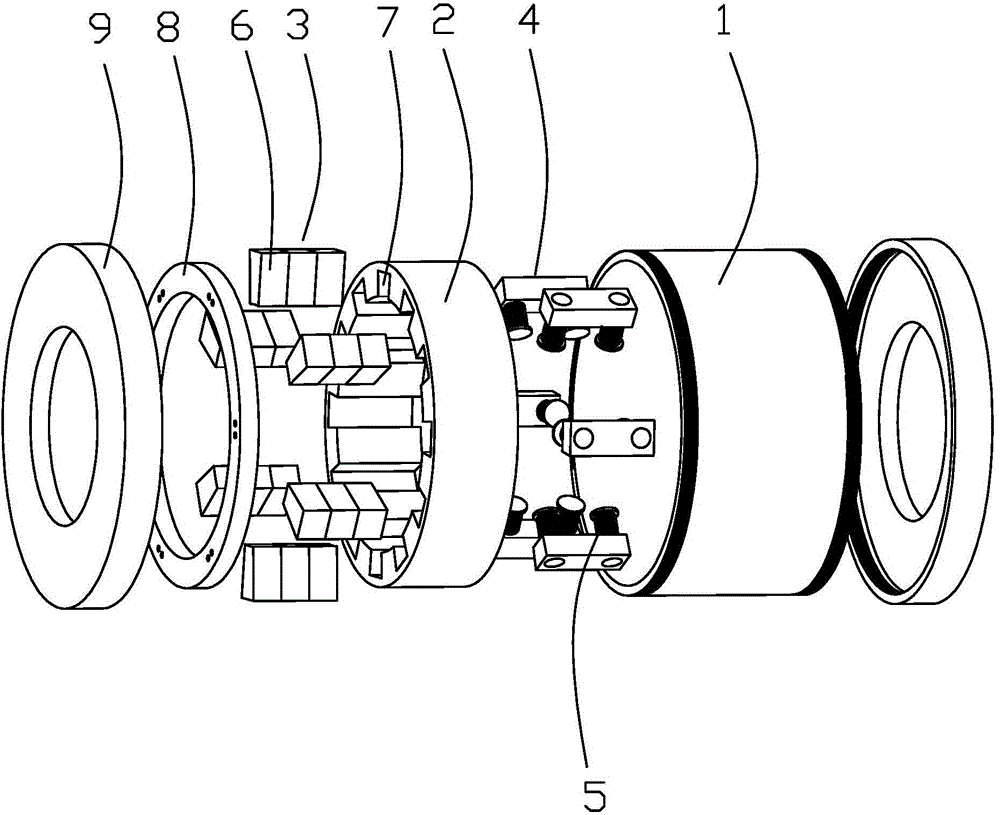

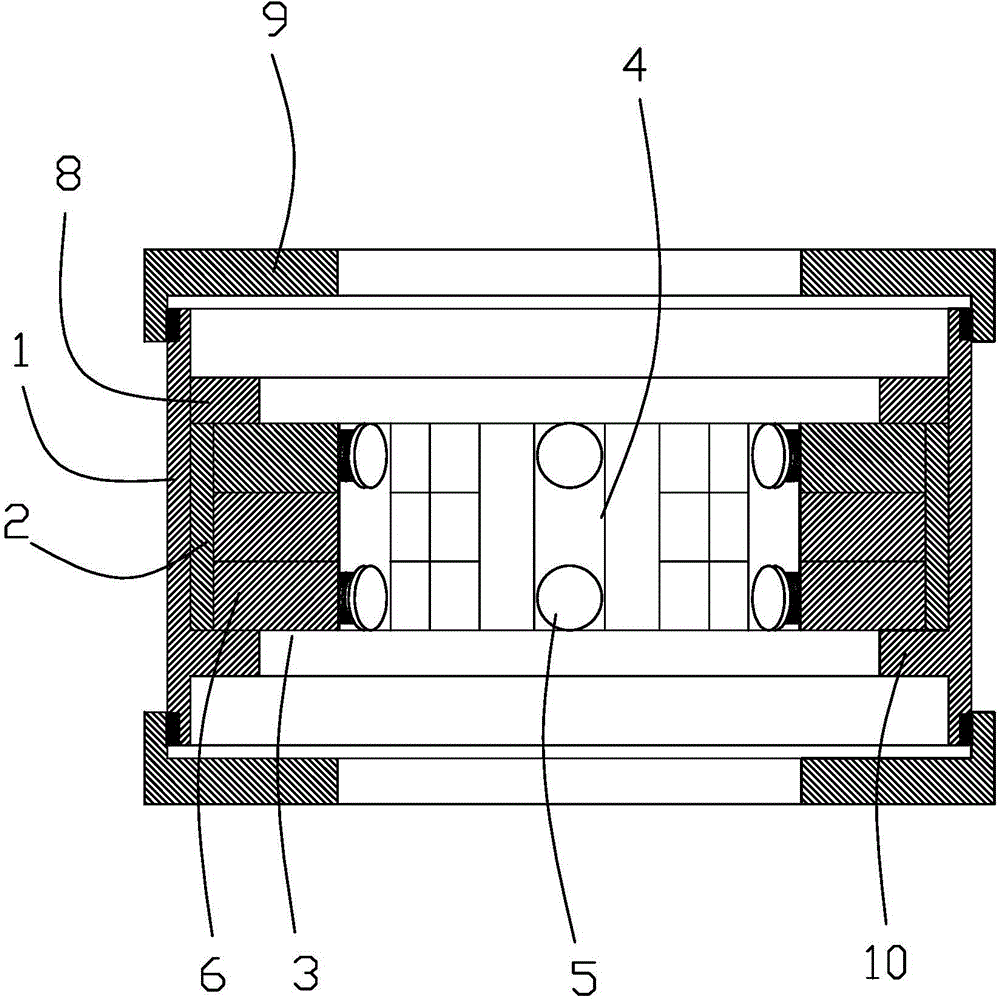

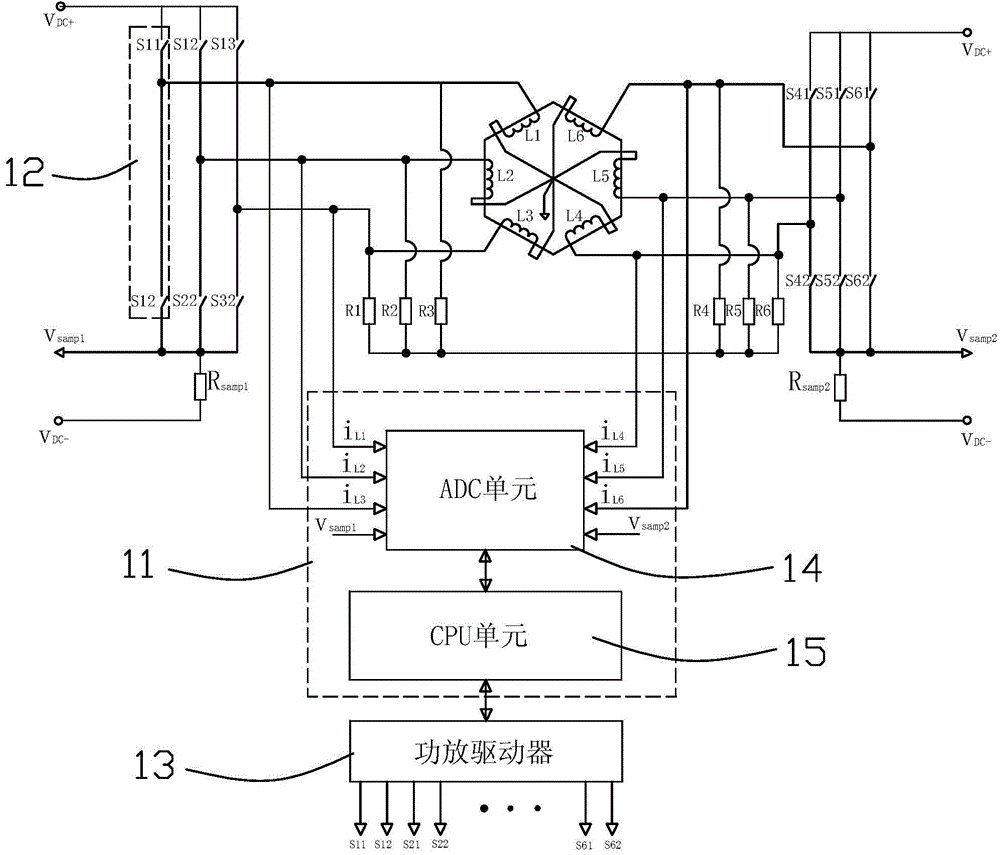

[0031] This embodiment is a homopolar single-ring hybrid magnetic bearing, and the magnetic bearing includes a stator, a rotor and a control system. Such as figure 1 As shown, the stator includes a bearing housing 1, and an inner core composed of an electromagnet 4 and a permanent magnet combination block 3 is arranged in the bearing housing. In this embodiment, a 6-pole magnetic bearing is used. The electromagnet has 6 groups, and the permanent magnet combination There are also 6 groups corresponding to the blocks. Magnetic pole heads 5 are arranged at both sides of the electromagnet, and coils are wound on the magnetic pole heads. The permanent magnet combination block is composed of three permanent magnets 6, and the three permanent magnets are arranged in a Halbach discrete array structure, such as Figure 4 As shown, the rotor is above the permanent magnets, the N poles of the permanent magnets in the middle are facing the rotor in the center of the bearing, and the N p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com