Air filter gas inlet pipeline arrangement method and structure for improving engine power performance

A technology of intake pipeline and layout structure, applied in the direction of fuel air filter, etc., can solve the problems of reducing engine power, air intake volume, engine power, etc., so as to improve power performance and reduce intake vortex generation. , the effect of a small number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

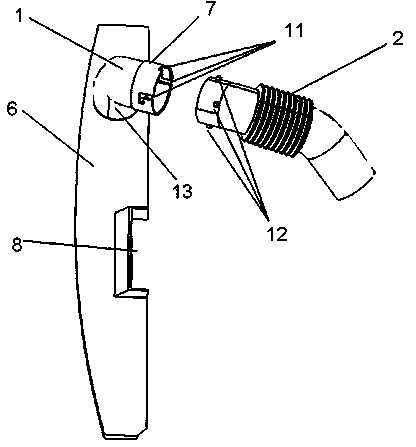

[0022] see figure 1 and figure 2 , the intake pipeline of the air filter includes an integral molding consisting of an overhead windshield 6 and an intake elbow 1 , a decoupling bellows 2 , an intake pipe 3 and a side windshield 5 .

[0023] The overhead windshield 6 and the intake elbow 1 are directly injection molded, and the overhead windshield 6 has an air inlet 13, and the intake elbow 1 is connected to the air inlet. Wherein, in the middle position of the top windshield 6 is an avoidance hole 8, which is used to install the radiator strengthening bracket. The top windshield 6 is connected with the top attachment of the condenser 10 through two bolts, and is basically flush with the upper edge of the condenser 10. Flat, and close to the front of the condenser 10, the position of the air inlet of the air filter is firmly fixed in front of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com