Full-thread anchor rod pre-tightening force exerting device capable of achieving automatic anchor unloading and operation method

A technology of applying device and pre-tightening force, which is applied in the installation of bolts, earth-moving drilling, mining equipment, etc., can solve the problems of inability to quantify, low torque conversion coefficient, high labor intensity, etc. The effect of precise force application and simplified construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

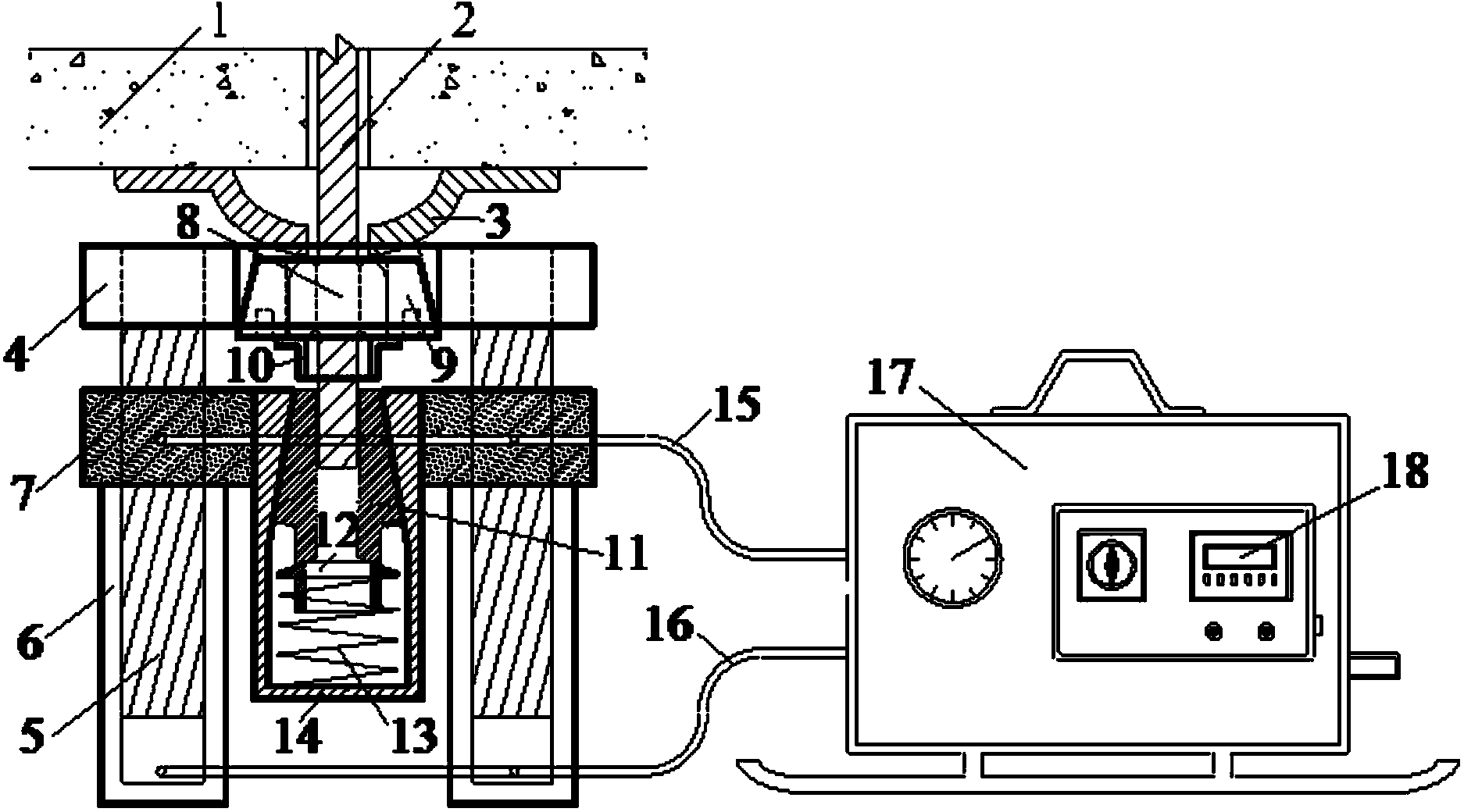

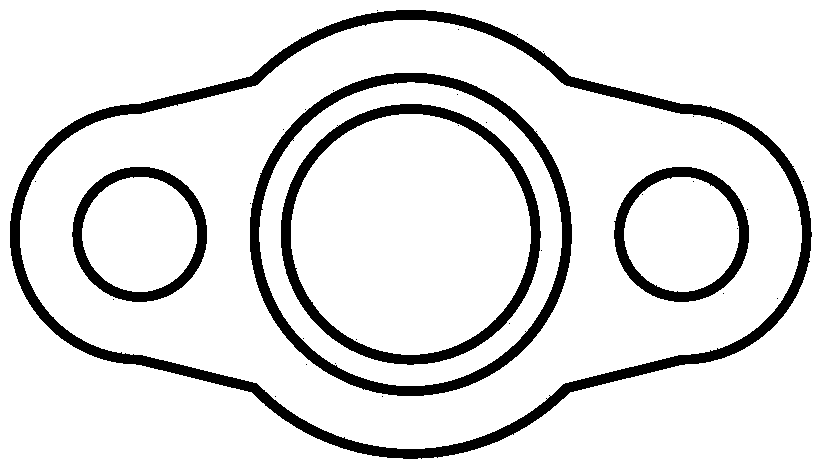

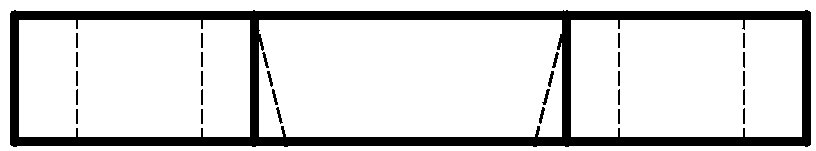

[0056] The fully threaded bolt pretightening force application device that can automatically withdraw the anchor consists of a front beam 4, a hydraulically retractable pillar 5, an oil cylinder 6, a rear beam 7, a tapered nut 9, a locking plate 11, a tapered sleeve 12, High-strength spring 13, pneumatic fuel tank pump 17, stepless shift controller 18 and digital display torque wrench 19 etc. are composed. Among them, the wind pressure is input into the air-driven oil tank pump 17 through the air inlet, and after the locking plate 11 in the lock sleeve 14 clamps the anchor rod, the output working load of the oil cylinder 6 can be set by adjusting the stepless shift controller 18 to realize full thread Quantitative tensioning of bolt preload.

[0057] The middle part of the front beam 4 is provided with a conical hole, and the angle of the conical surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com