New garbage collection and hauling device

A new type of garbage collection technology, applied in vertical pipelines, building components, buildings, etc., can solve the problems of low production efficiency, dust emission and noise disturbance, and large amount of on-site handling by workers, so as to improve construction efficiency and reduce dust. Generate and reduce the effect of noise nuisance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

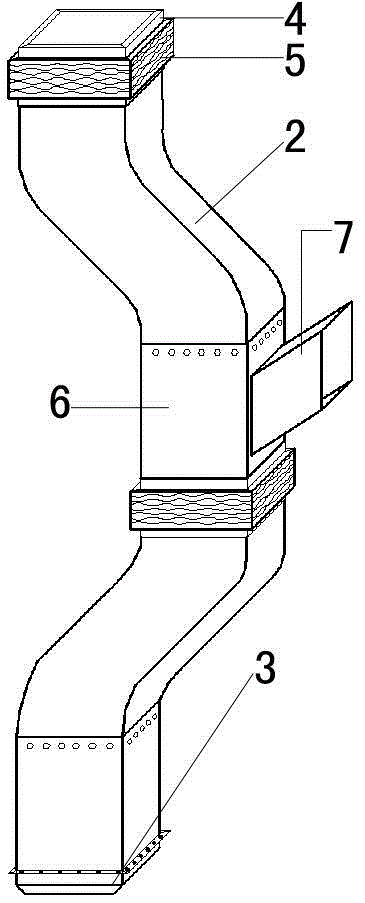

[0025] Example: such as figure 1 , figure 2 As shown, a novel garbage collection and hauling device includes a primary buffer reducer 2, a secondary reducer 3, a flexible shock-absorbing belt, and a template 6.

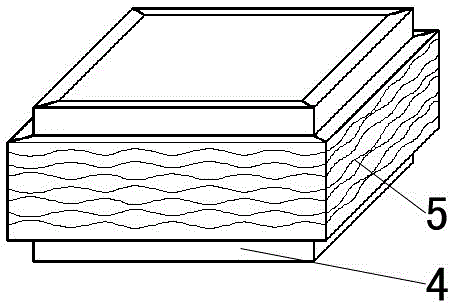

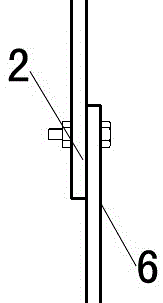

[0026] The flexible shock absorbing belt, the primary buffer reducer 2, the template 6, and the secondary reducer 3 are connected in sequence to form a unit structure; the template 6 is provided with a feeding port 7, and the connecting part is surrounded by a thin iron sheet and fixed with screws. 7 is connected to the main channel, and the feeding port 7 is at an angle of 30 to 45 degrees with the horizontal plane; the unit structures are connected by flexible shock-absorbing belts to form a complete system. The unit structure of the new garbage collection and hauling device is S-type or Z-type, and the unit structures of the S-type or Z-type are connected in series.

[0027] The primary buffer reducer 2 is an iron rigid shell; the inner surface of the primary bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com