Detachable compression dustbin

A garbage bin and pin shaft technology, which is applied in the direction of garbage storage, transportation and packaging, etc., can solve the problems of automatic opening, hydraulic oil leakage, and force displacement of the piston rod of the oil cylinder, etc., and achieve high reliability and open and close action flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

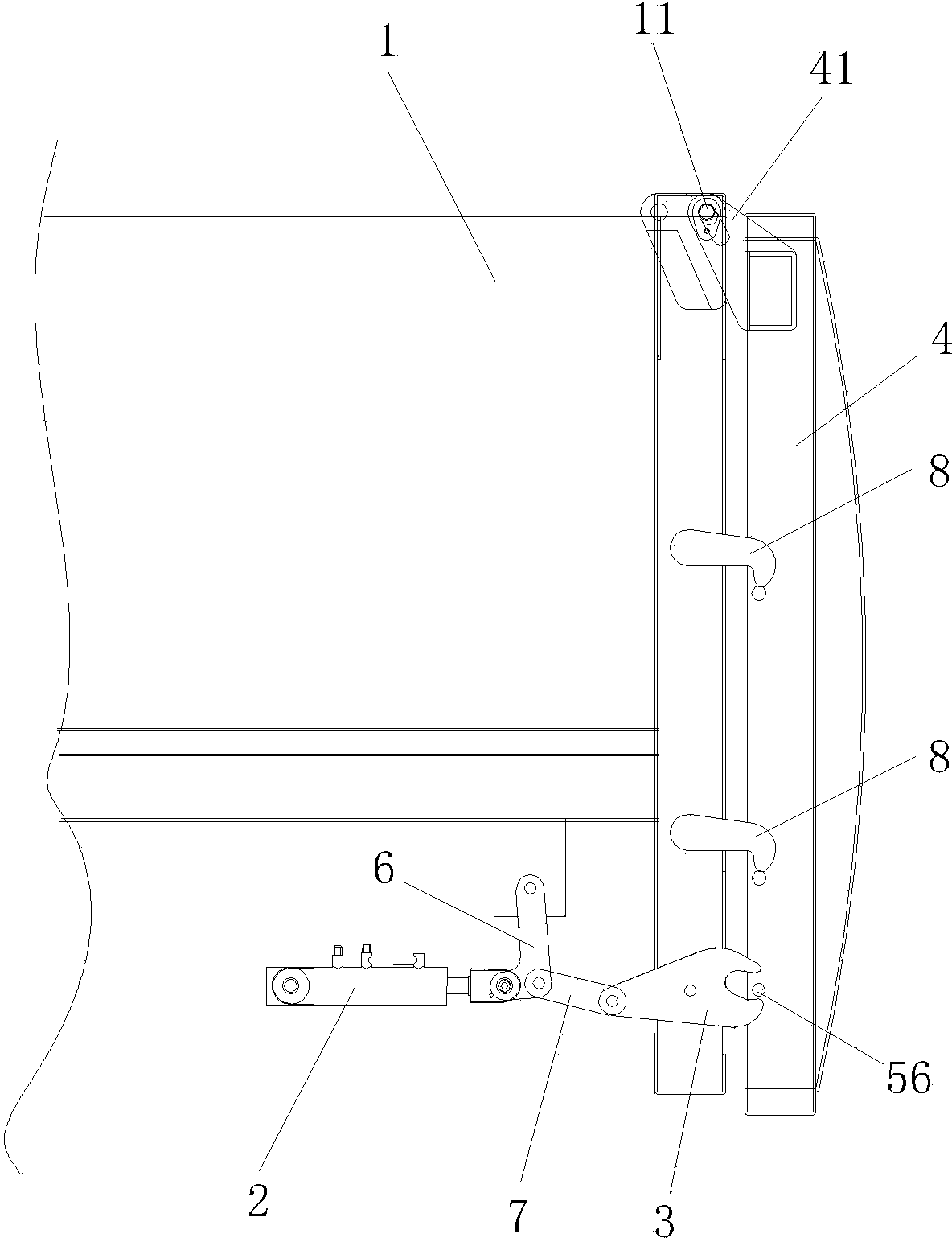

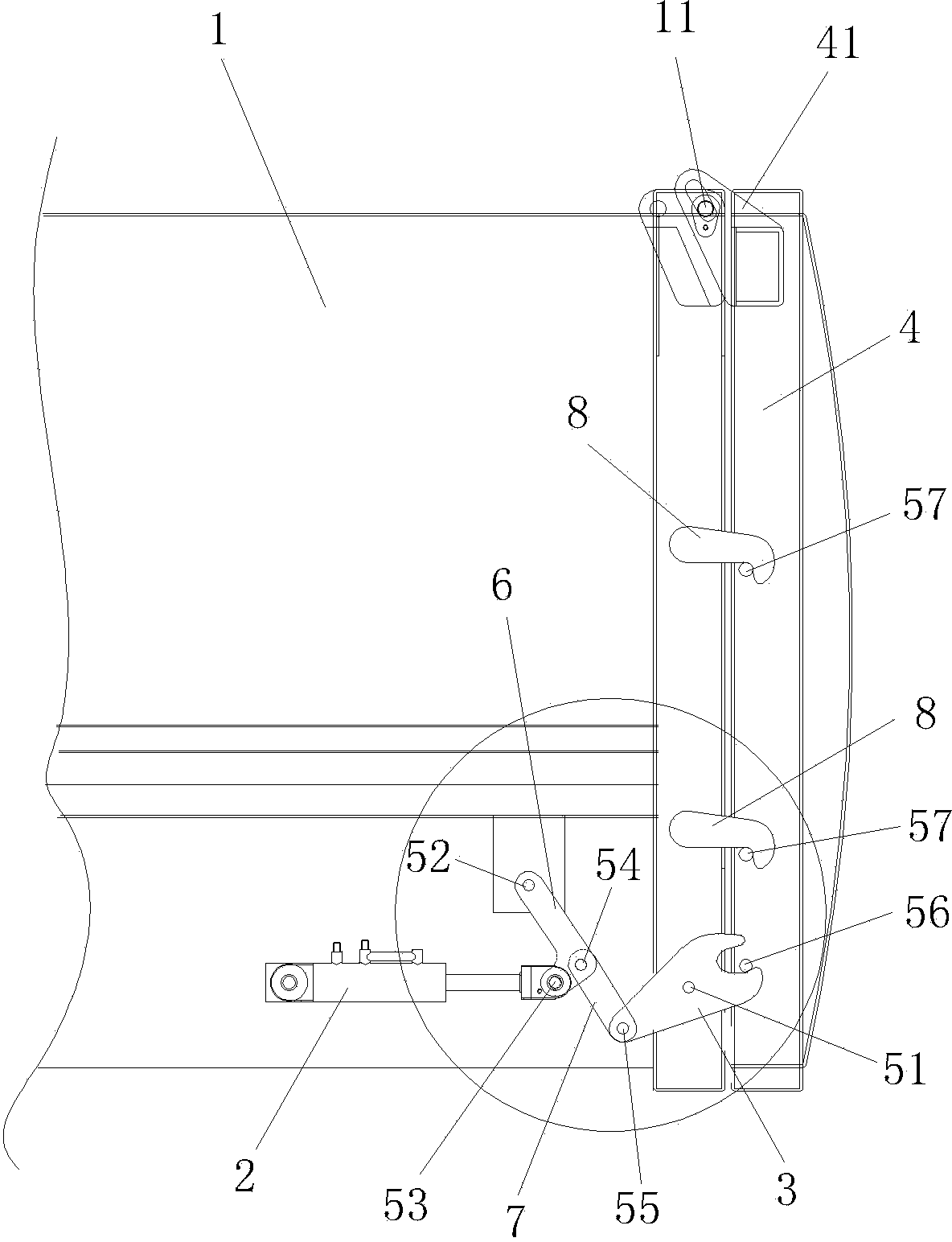

[0021] Figure 1 to Figure 5 As shown in the figure, a detachable compressed waste container includes a waste container body 1, a rear door 4, and a rear door locking mechanism. The rear door locking mechanism includes two locking oil cylinders 2, Two locking arms 3, two hanging lugs 41 are fixed on the upper ends of the two sides of the rear door 4, two hinge shafts 11 are disposed on the rear upper ends of the two sides of the dustbin body 1, and the two hanging lugs 41 are provided with long strips. The hinged through holes 411, the two hanging ears 41 are respectively sleeved on the two hinge shafts 11 by the elongated hinged through holes 411;

[0022] A first pin shaft 51 and a second pin shaft 52 are fixed at intervals on the rear lower parts of the two sides of the garbage box body 1, and the middle parts of the two locking arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com