Cylinder head camshaft oil hole chamfering device

A technology of chamfering device and camshaft, used in positioning devices, drilling/drilling equipment, clamping and other directions, can solve the problems of low chamfering efficiency and poor chamfering quality, and achieve high chamfering efficiency and chamfering. The effect of good quality and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below with reference to the drawings.

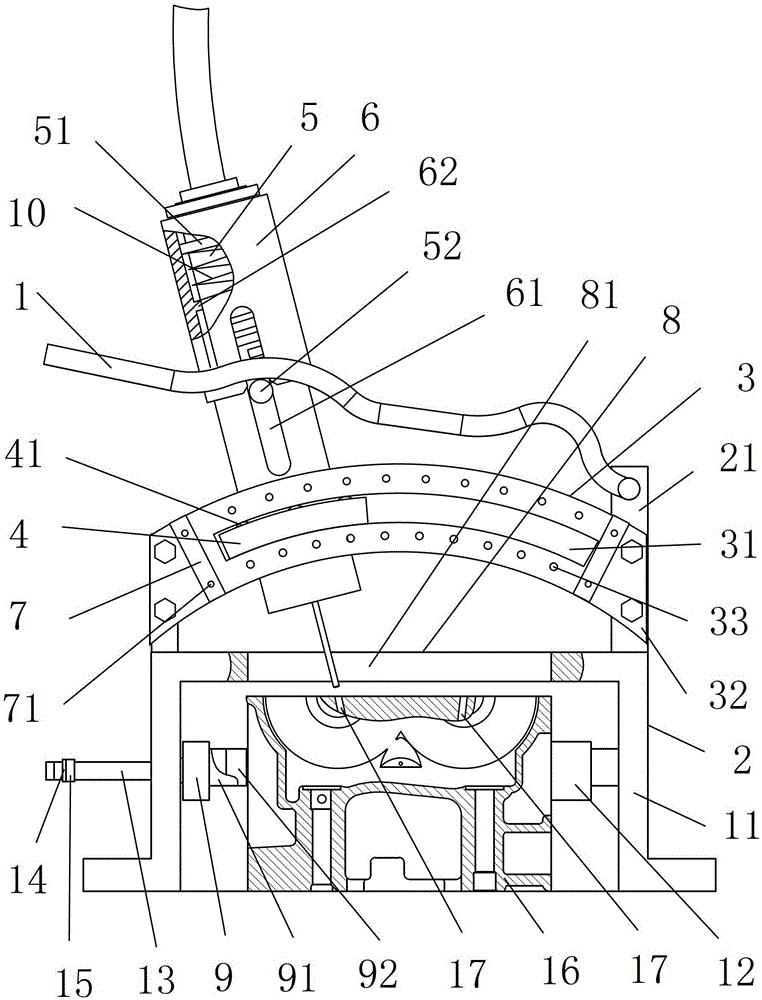

[0016] As attached figure 1 , Attached figure 2 Shown: a cylinder head camshaft oil hole chamfering device, comprising a support 2 with two upper side plates 21, a cross beam 3 with an arc-shaped sliding groove 31 and two ends connected with an upper side plate 21, It has a chamfering mechanism and a rotation angle limiting mechanism of the slider 4 that are matched with the arc-shaped sliding groove 31.

[0017] In this embodiment, the cross beam 3 includes two supporting plates 32 whose ends are each screwed to the side ends of an upper side plate 21; each arc-shaped sliding groove 31 is located on a supporting plate 32 and penetrates the supporting plate. The two sides of 32; the arc-shaped sliding groove 32 takes the intersection of the axes of the camshaft oil holes 17 of the two cylinder heads 16 as the axis.

[0018] The chamfering mechanism includes a pneumatic drill 5 with an up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com