Rubber-coated rand assembly

A technology of encapsulation and components, applied in the direction of pipes/pipe joints/fittings, hose connection devices, mechanical equipment, etc., can solve the problems of lack of positioning structure, complicated process, and easy air leakage at the joints of hose ends, etc. Achieve the effects of reliable positioning, overcoming air leakage defects, and free loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

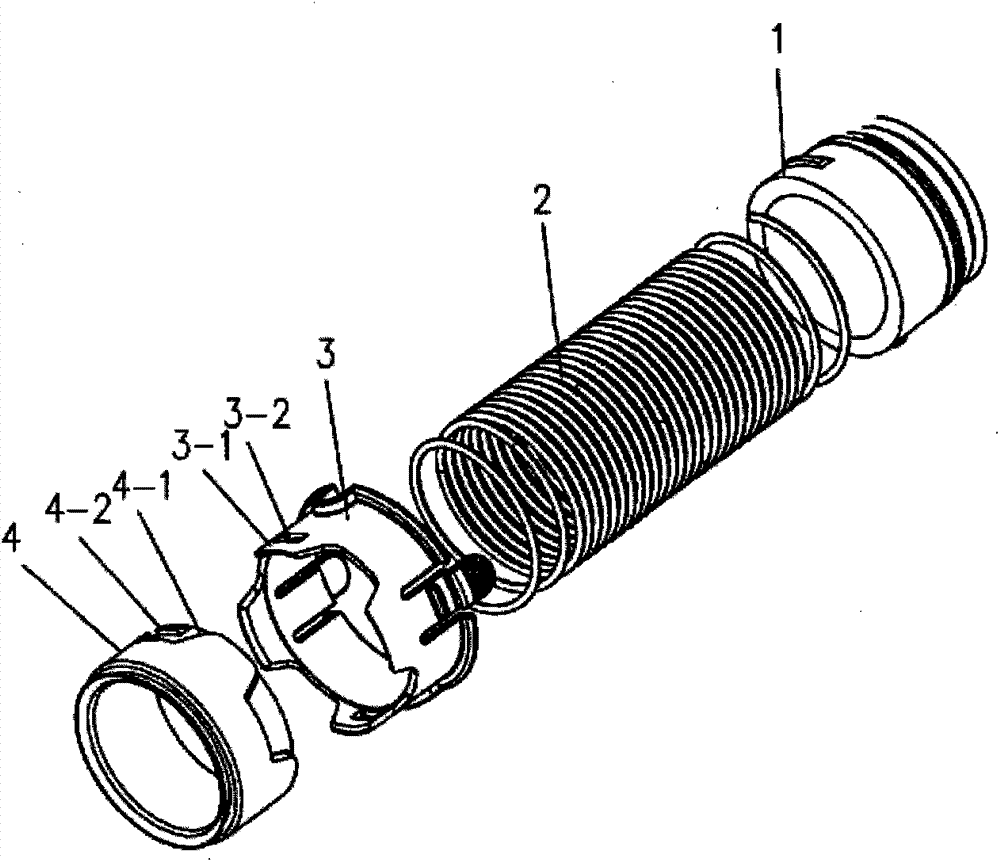

[0016] The rubberized collar assembly of this embodiment is as figure 1 , 2 , 3, including the corrugated hose main body 2 made by spirally winding the PVC base strip lined with steel wire according to the conventional process. Rubber joint 4. The two rubber-coated joints 1 and 4 are all through the injection molding process, and the inner ends are respectively coated on the ends of the corresponding telescopic hose main body 2, and form a radial concave-convex fitting structure with the corrugated hose main body 2, and are connected with it as a whole. During actual production, the spirally wound base strips at both ends of the corrugated hose main body 2 are stretched so that adjacent base strips form gaps with each other. In the rubberized joint 1 or 4, a radial concave-convex fitting structure firmly integrated is formed. The outer ends of the two rubber joints 1 and 4 respectively form extended bell mouths, thereby becoming a bell mouth-shaped circumferential sealing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com