Hybrid magnetic bearing and control method thereof

A technology of magnetic bearing and control method, applied in the direction of bearing, shaft and bearing, mechanical equipment, etc., can solve the problems of installation and wiring occupying space, insufficient balance, difficult maintenance and calibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

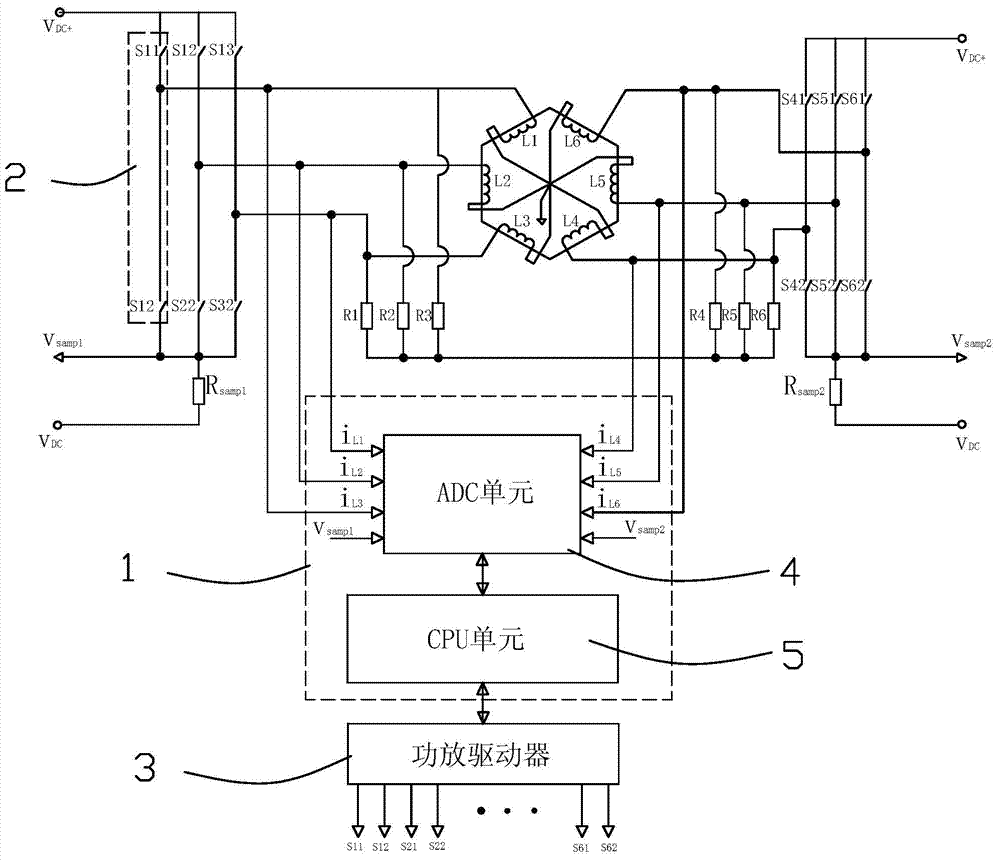

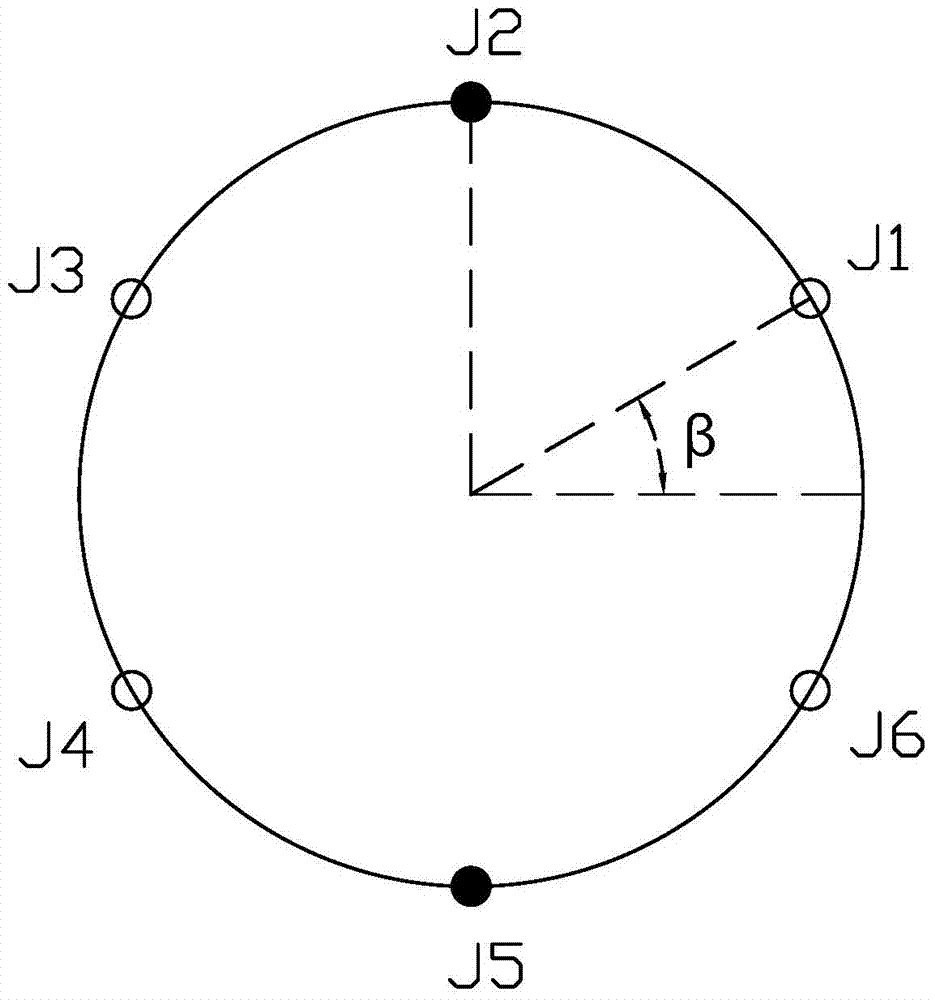

[0049] This embodiment is a hybrid magnetic bearing, and the magnetic bearing control method, the bearing includes a stator, a rotor and a control system, the stator includes a permanent magnet array and an electromagnet array surrounding the rotor, and the electromagnet array is composed of at least 6 or more even-numbered electromagnetic Each electromagnet forms a magnetic pole. In this embodiment, a 6-pole bearing is taken as an example, such as figure 1 As shown, the control system includes 6 switch pairs, a power amplifier driver 3, and a digital signal processor 1. The digital signal processor 1 includes an ADC unit 4 and a CPU unit 5. The ADC unit is connected to the CPU unit, and each switch pair corresponds to connected to an electromagnet coil, the ADC unit is respectively connected to each electromagnet coil, the CPU unit is connected to a power amplifier driver, and the power amplifier driver controls and connects each switch pair. The switch pair is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com