Optional voltage drain circuit structure

A circuit structure and drainage technology, applied in the field of optional voltage drainage circuit structure, can solve the problems of inability to distinguish pipeline induced interference, difficult monitoring and maintenance, pipeline hydrogen evolution reaction, etc., and achieve safe, reliable and economical pipeline drainage operation. Operating cost, effect of avoiding hydrogen evolution reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

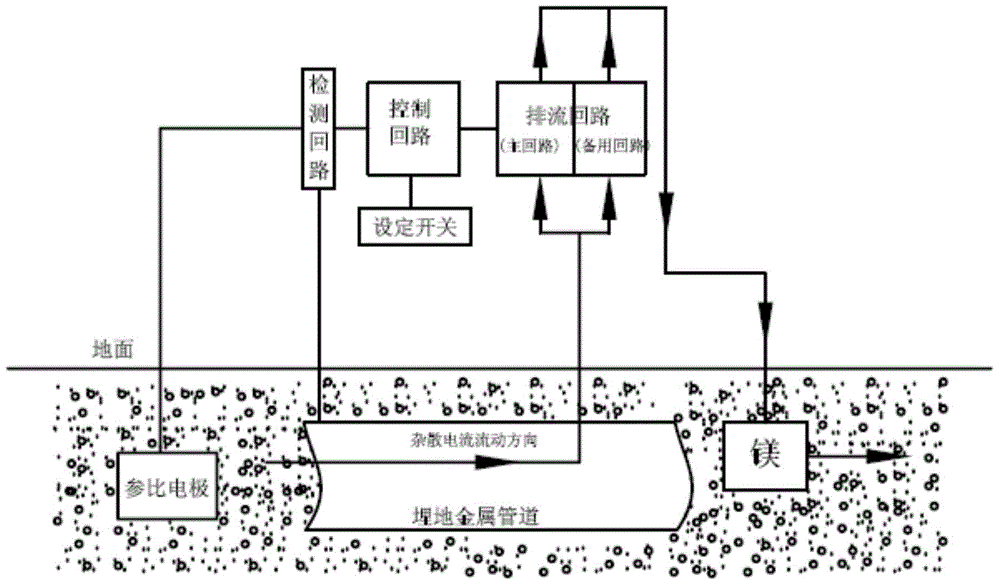

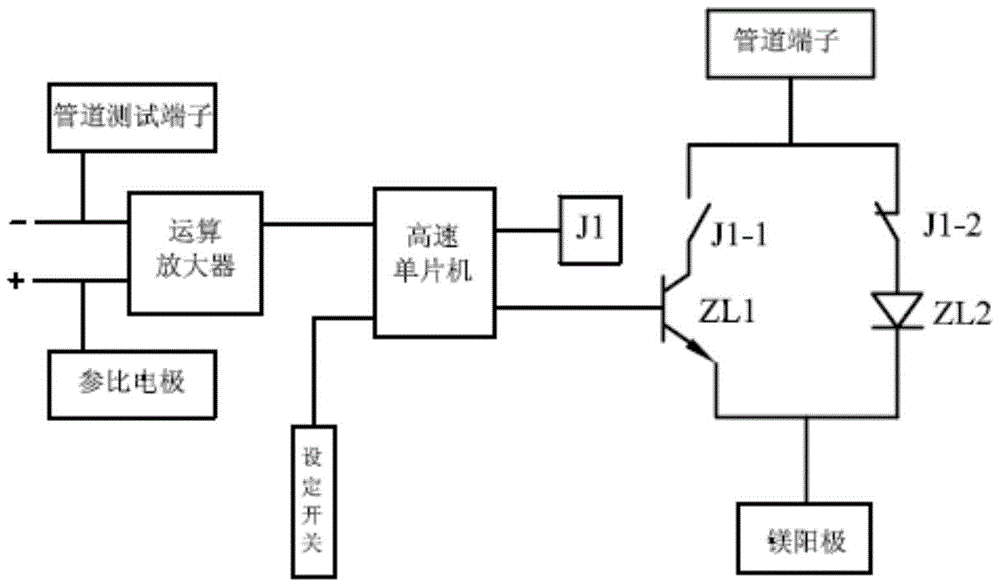

[0019] The structure of the optional voltage drain circuit of the present invention is described in conjunction with the accompanying drawings.

[0020] The design idea of the optional voltage type drainage circuit structure of the present invention is based on the fact that the cathodic protection potential is set according to the use conditions, and the drainage can be performed only when the setting conditions are met, and the cathodic protection voltage is set according to the environmental conditions, so as to realize Intelligent circuit structure that needs drainage. Connect one end of the drainage circuit to the metal pipe, and the other end to the magnesium anode, compare the measured voltage of the pipe with the preset voltage of the setting switch through the detection circuit, and according to the logical judgment result, the control circuit determines whether the drainage circuit is conducting Still due. At the same time, the drainage circuit is equipped with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com