A kind of high bonding strength insulating paint for titanium alloy surface insulating protective layer

A technology combining strength and insulation protection, applied in the direction of epoxy resin coating, coating, etc., can solve the problems of poor adhesion and achieve the effect of insulation protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Preparation of toughening modifier:

[0037] Mix 30 parts of nitrile rubber CTBN and 40 parts of epoxy resin E5140 parts by mass, heat to 80°C, and stir evenly; add 0.2 parts of triphenylphosphine to the evenly stirred mixture, heat to 120°C, react for 4 hours, and cool to obtain toughening modifier.

[0038] 2) Preparation of high bonding strength insulating coatings for the surface of titanium alloys:

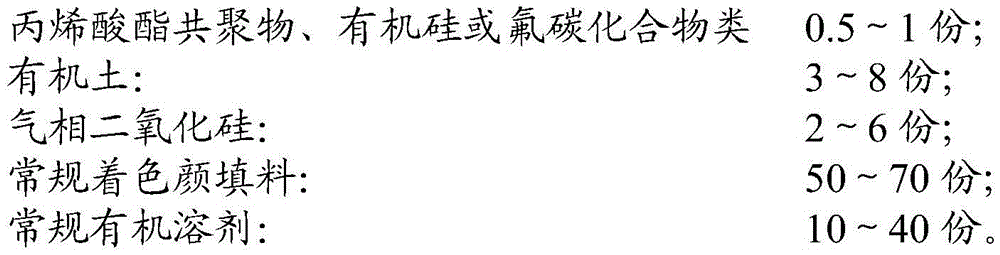

[0039] In proportion, 60 parts of bisphenol A epoxy resin 6101 film-forming resin, 20 parts of the above-mentioned toughening modifier, 3 parts of epoxy group silane coupling agent KH-560 adhesion promoter, modified polysiloxane Defom5500 0.3 parts of defoamer, 0.5 parts of acrylate copolymer Levelol495 leveling agent, 3 parts of organic soil, 2 parts of fumed silica, 50 parts of iron oxide red pigment, the solvent is xylene and butanol in a volume ratio of 6:4 10 parts of the mixed mixture, mixed uniformly to make a high bonding strength insulating coating for th...

Embodiment 2

[0043] 1) Preparation of toughening modifier:

[0044] Mix 50 parts of nitrile rubber CTBN and 160 parts of epoxy resin E5160 parts by mass, heat to 80°C, and stir evenly; add 0.6 parts of triphenylphosphine to the evenly stirred mixture, heat to 120°C, react for 4 hours, cool to obtain toughness modifier.

[0045] 2) Preparation of high bonding strength insulating paint for titanium alloy surface:

[0046] 90 parts of bisphenol A epoxy resin 6101 film-forming resin in proportion, 40 parts of toughening modifier prepared as above, 8 parts of aminosilane coupling agent KH-550 adhesion promoter, modified polysiloxane Defom5500 0.8 parts of defoamer, 1 part of acrylate copolymer Levelol495 leveling agent, 8 parts of organic soil, 6 parts of fumed silica, 70 parts of iron oxide red pigment, the solvent is xylene and butanol in a volume of 6:4 The ratio is 40 parts of mixed solvent, and it is evenly mixed to prepare high bonding strength insulating coating for the surface of tita...

Embodiment 3

[0050] 1) Preparation of toughening modifier:

[0051] Mix 40 parts of nitrile rubber CTBN and 515 parts of epoxy resin E515 parts by mass, heat to 80°C, and stir evenly; add 0.5 part of triphenylphosphine to the evenly stirred mixture, heat to 120°C, react for 4 hours, cool to obtain toughness modifier.

[0052] 2) Preparation of high bonding strength insulating paint for titanium alloy surface:

[0053] In proportion, 70 parts of bisphenol A epoxy resin 6101 film-forming resin, 30 parts of the above-mentioned toughening modifier, 5 parts of aminosilane coupling agent KH-550 adhesion promoter, and modified polysiloxane Defom5500 defoamer 0.6 parts, 0.7 parts of acrylate copolymer Levelol495 leveling agent, 6 parts of organic soil, 4 parts of fumed silica, 60 parts of iron oxide red pigment, the solvent is a mixture of xylene and butanol in a volume ratio of 6:4 20 parts of solvent, mixed uniformly to prepare high bonding strength insulating coating for titanium alloy surface....

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com