Yarn monitoring device and yarn winding machine

A technology of yarn winding machine and monitoring device, which is applied in transportation and packaging, delivery of filamentous materials, thin material processing, etc., and can solve problems such as unqualified packages, end face falling off, and yarn skipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

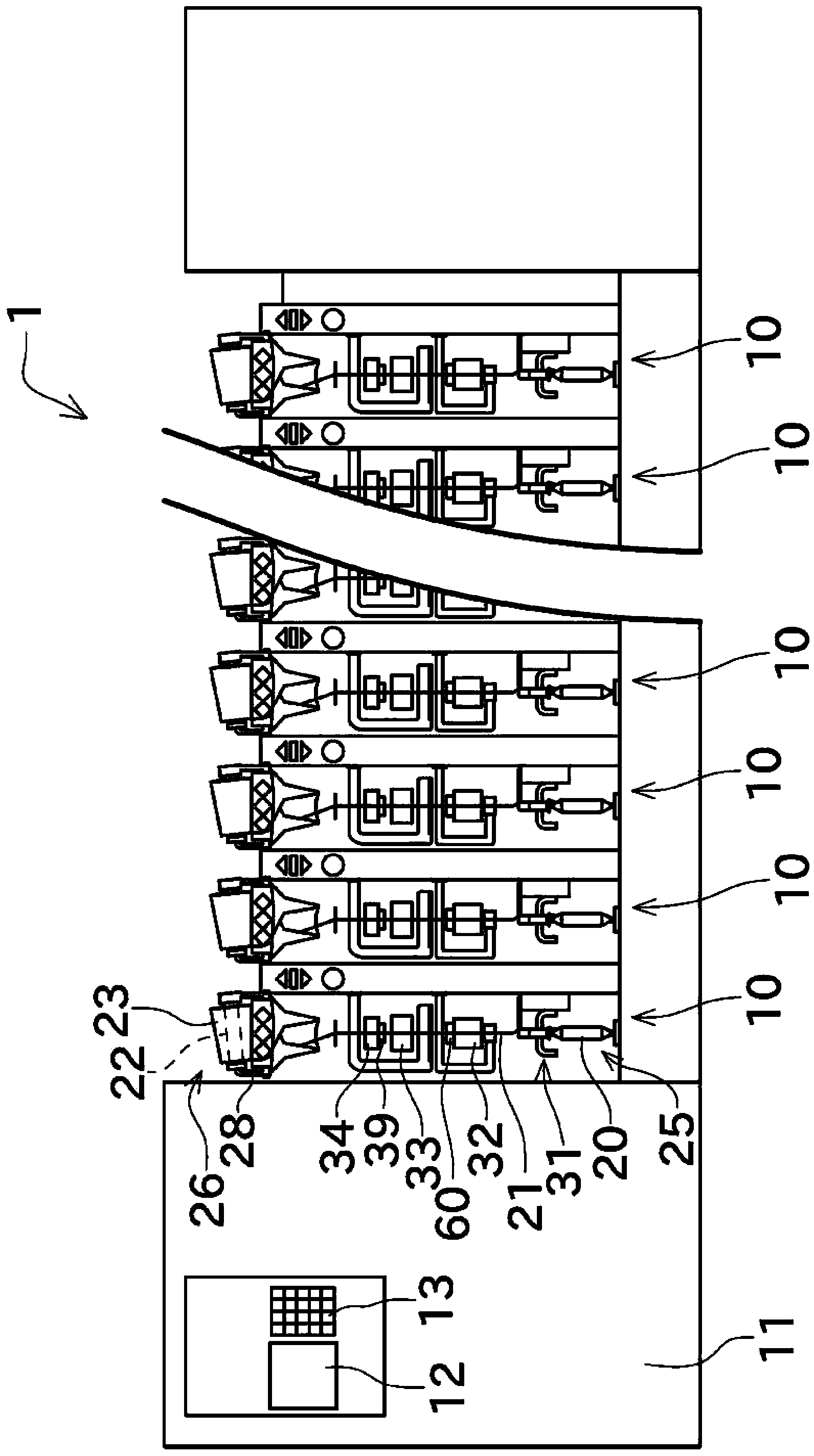

[0027] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. Such as figure 1 As shown, an automatic winder (yarn winding machine) 1 according to an embodiment of the present invention has a plurality of winder units (yarn winding units) 10 arranged in a row and a machine body arranged at one end of the arrangement direction. control unit 11.

[0028] The machine control unit 11 has a display device 12 capable of displaying information related to each winder unit 10, an instruction input unit 13 for an operator to input various instructions to the machine control unit 11, and the like. The operator of the automatic winder 1 can collectively manage a plurality of winder units 10 in the machine control unit 11 by checking various information displayed on the display device 12 and appropriately operating the instruction input unit 13 .

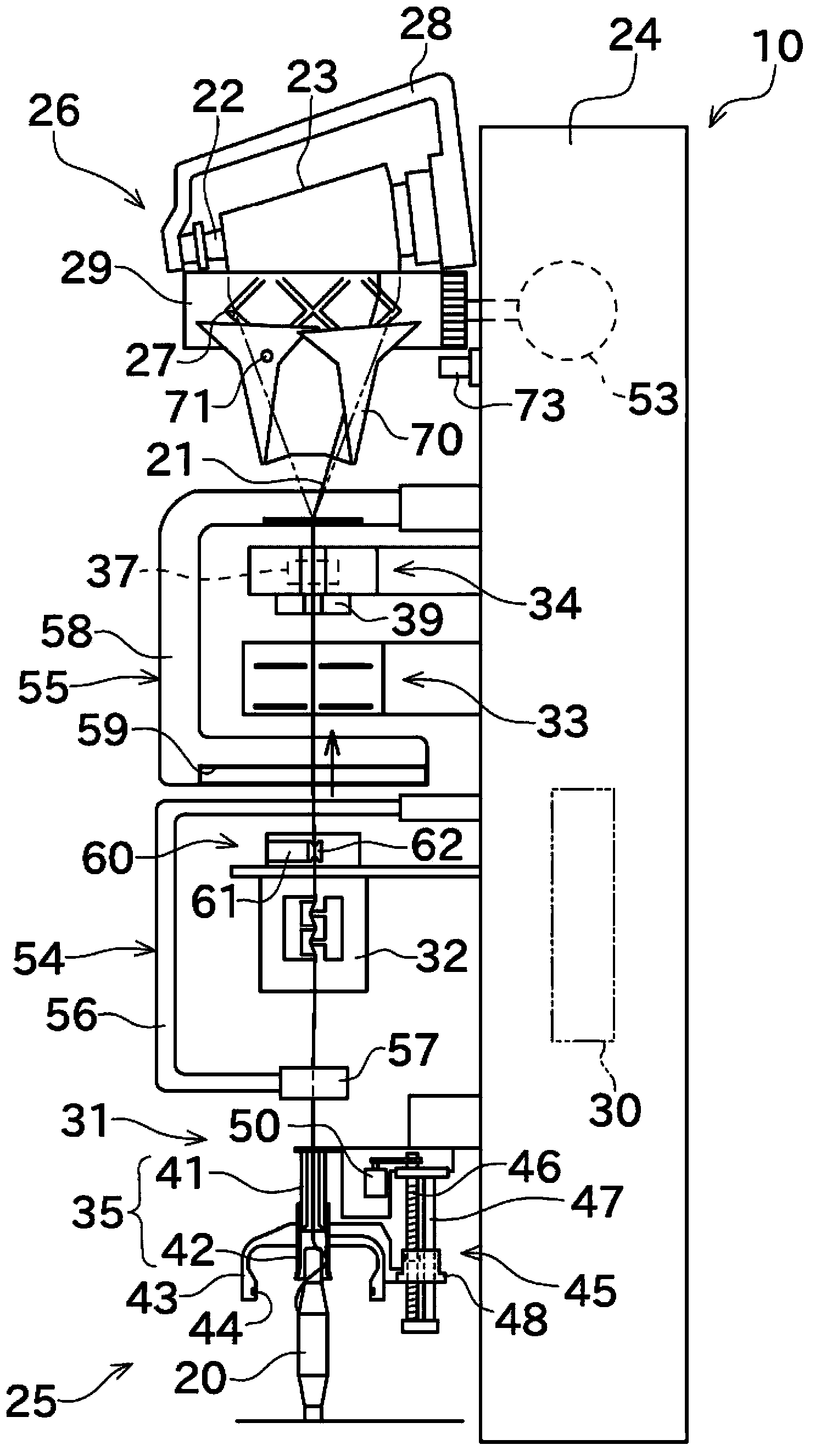

[0029] Each winder unit 10 unwinds the yarn 21 from the yarn supply bobbin 20 and unwi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com