Triggering continuous step climbing mechanism

A trigger-type, platform-climbing technology, applied in motor vehicles, transportation and packaging, etc., can solve problems such as poor adjustability, troublesome assembly, high center of gravity, etc., and achieve fast and stable transportation, stable operation, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

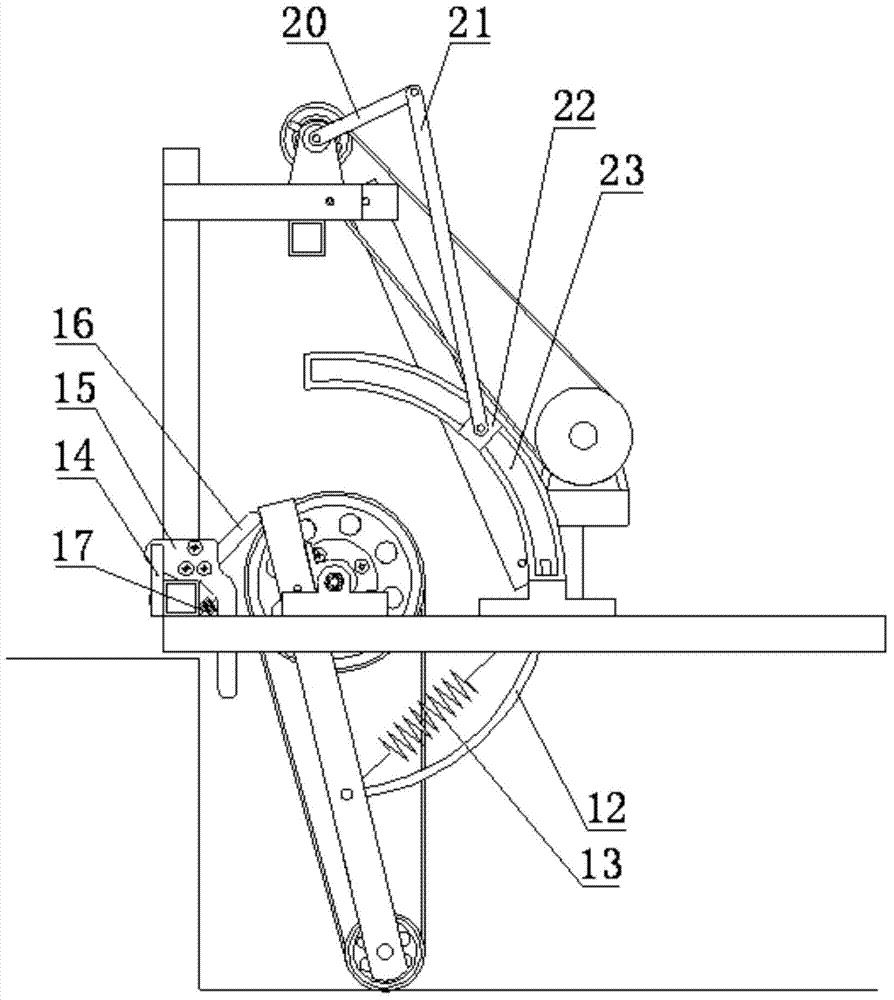

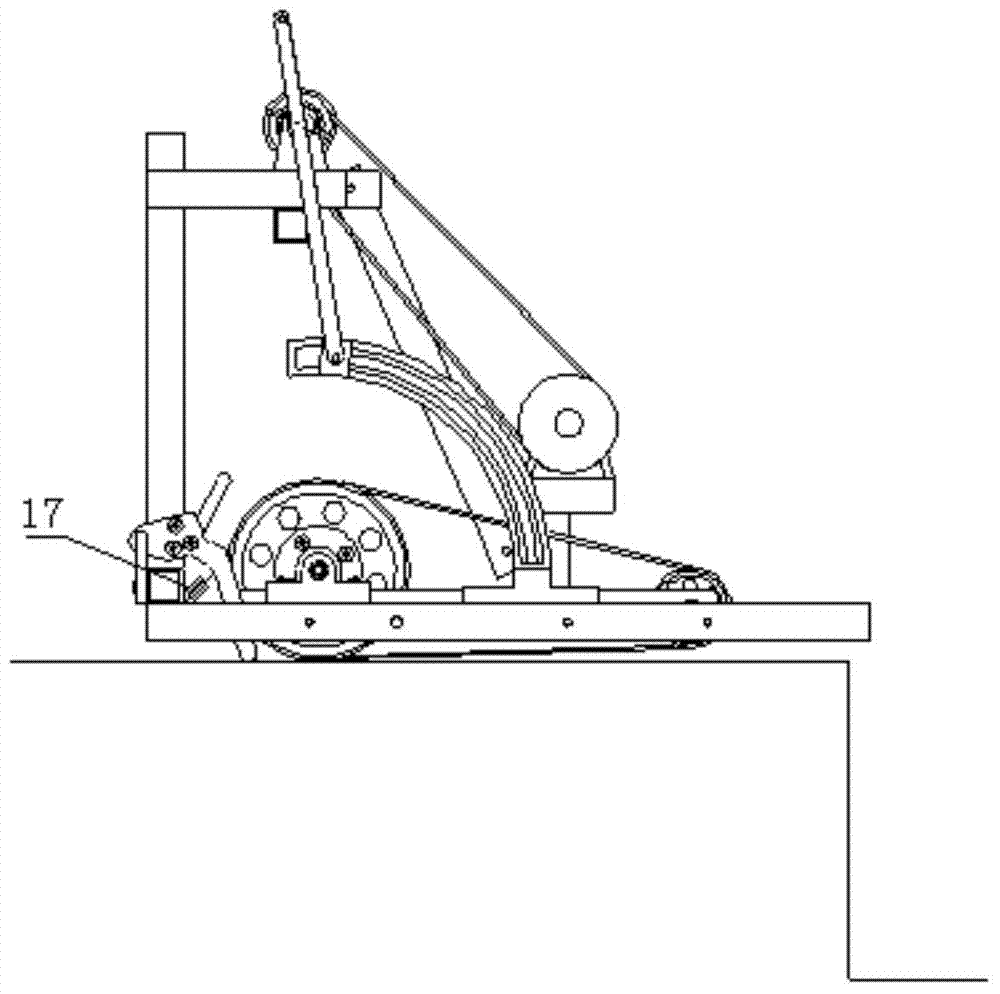

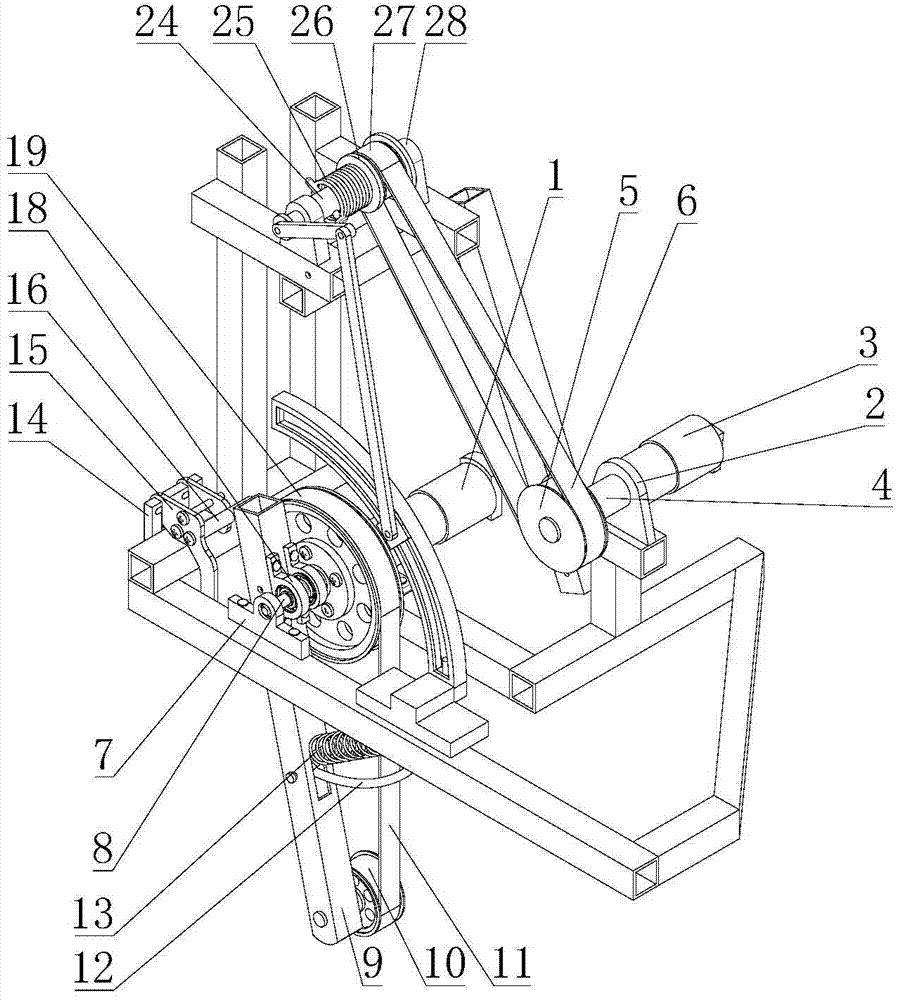

[0019] combine Figure 1-Figure 3 , The trigger type continuous platform climbing mechanism includes a support frame, a drive motor 1, a drive motor drive shaft 8, a drive motor bearing seat 7, a driving wheel 19, a driven wheel 10, a crawler belt 11, a rotating strut 9, and a rotating strut bearing seat 18 , Unstable leg tension spring 13, arc-shaped rod 12, slewing bearing 14, trigger lever 15, self-locking block 16, trigger mechanism tension spring 17, crank 20, connecting rod 21, slide block 22, chute 23 , rotating shaft 24, compression spring 25, friction plate 26, small pulley 27, rotating shaft bearing seat 28, motor 3, motor seat 2, transmission shaft 4, large pulley 5 and synchronous belt 6.

[0020] The chassis support of the car body includes a support frame and a drive motor 1 mounted on it, and the driving shaft 8 of the drive motor i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com