Vibration actuator

A vibration actuator and axis technology, which is applied to fluids, electrical components, and electromechanical devices that use vibration, can solve problems such as abnormalities and unstable vibrations, and achieve the effect of preventing abnormal sounds and stabilizing vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

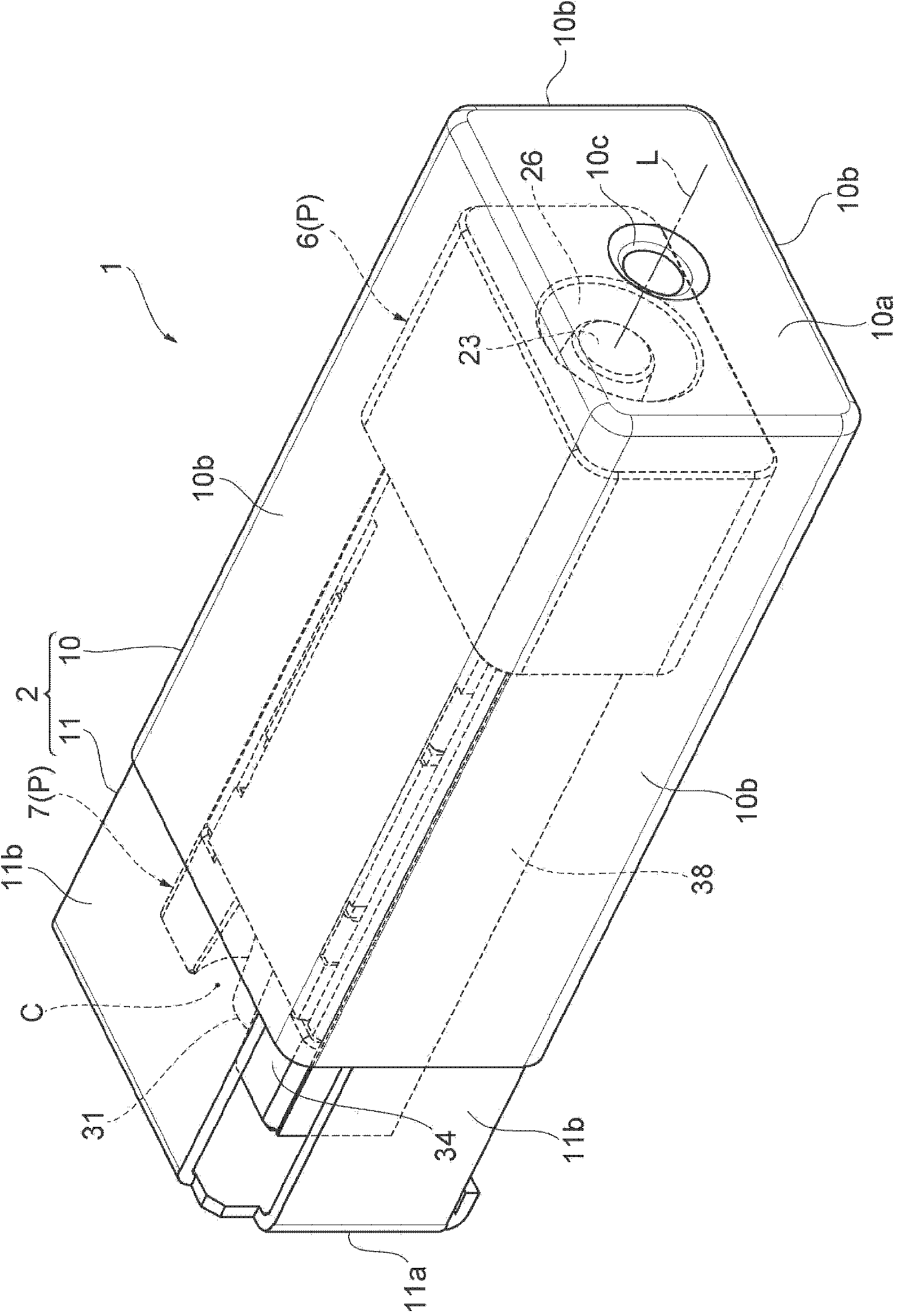

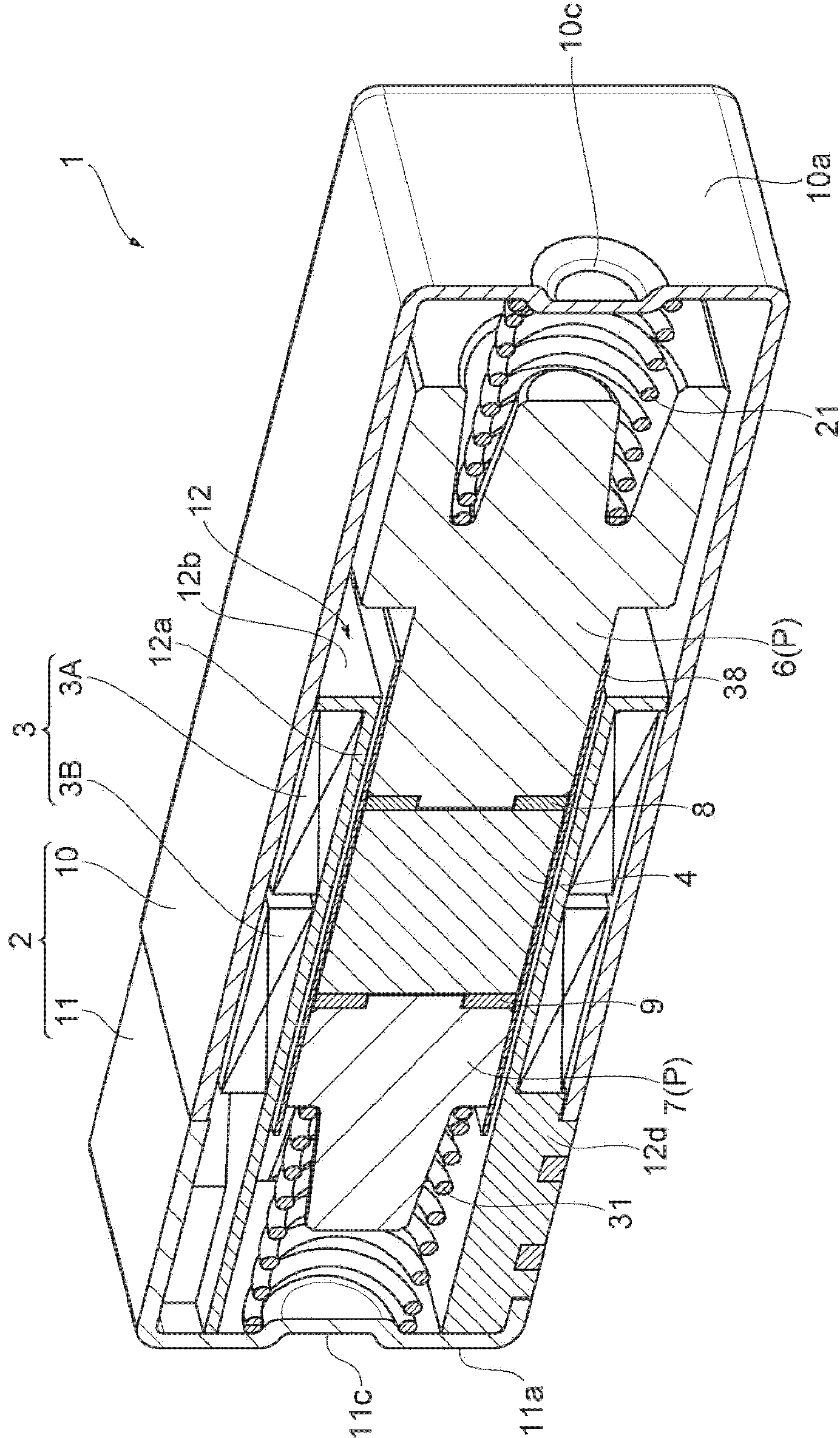

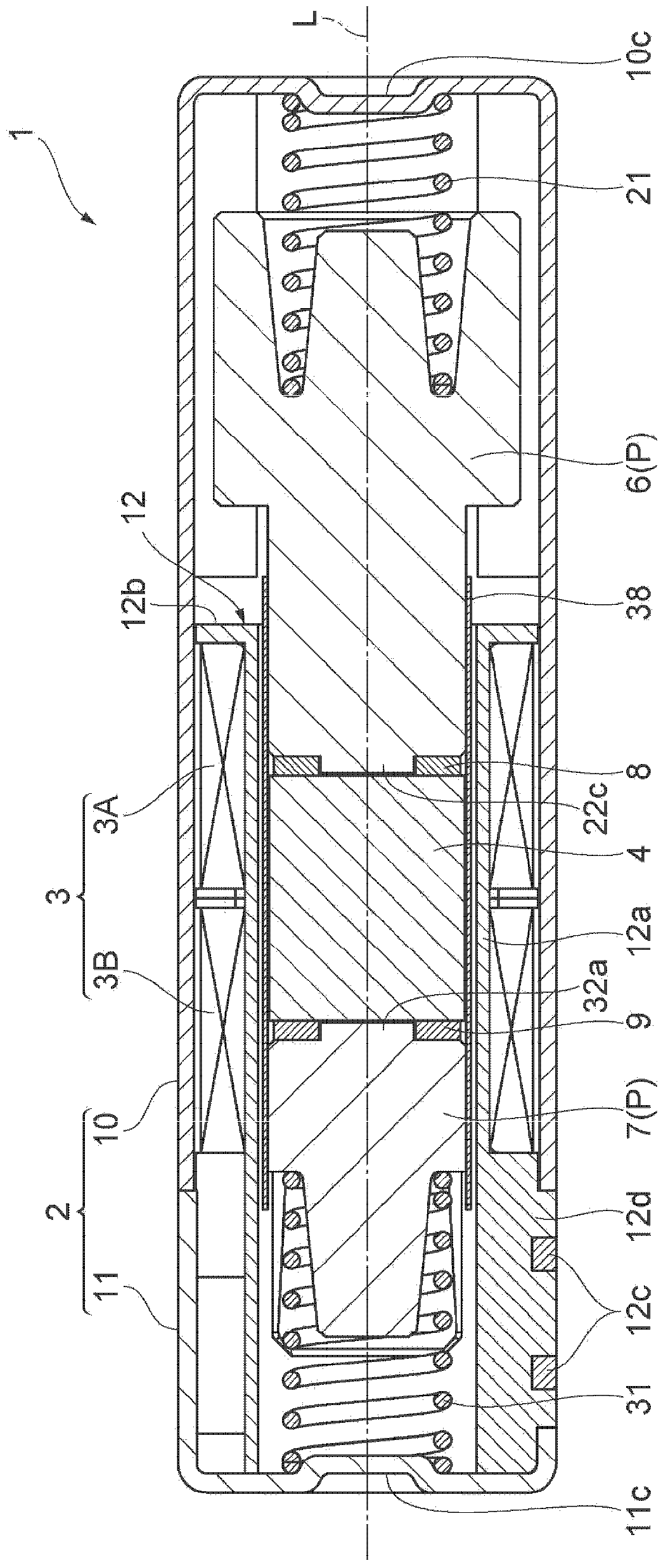

[0044] Hereinafter, preferred embodiments of the vibration actuator of the present invention will be described in detail with reference to the drawings.

[0045] Such as Figure 1 ~ Figure 3 As shown, a small vibration actuator 1 has a housing 2 composed of a hollow rectangular parallelepiped with a height of 4 mm x a width of 6 mm x a length of 15 mm. A coil 3 , a rectangular parallelepiped magnet 4 , a first weight 6 and a second weight 7 , and an annular first pole piece 8 and second pole piece are accommodated in a case 2 made of a magnetic body. 9, wherein the above-mentioned coil 3 is wound around the vibration axis L of the casing 2 to form a rectangular cross-section, the above-mentioned magnet 4 is surrounded by the coil 3, and the above-mentioned first hammer part 6 and the second hammer part 6 are arranged as Adjacent to both sides of the magnet 4 in the direction of the vibration axis L of the casing 2 , the first pole piece 8 and the second pole piece 9 are fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com