Electric motor rotor, electric motor, air conditioner, and production method for electric motor rotor

A manufacturing method and motor technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of cost increase, insulation part detachment, etc., and achieve the effect of preventing shaft current, preventing abnormal sound, and inhibiting electrical corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

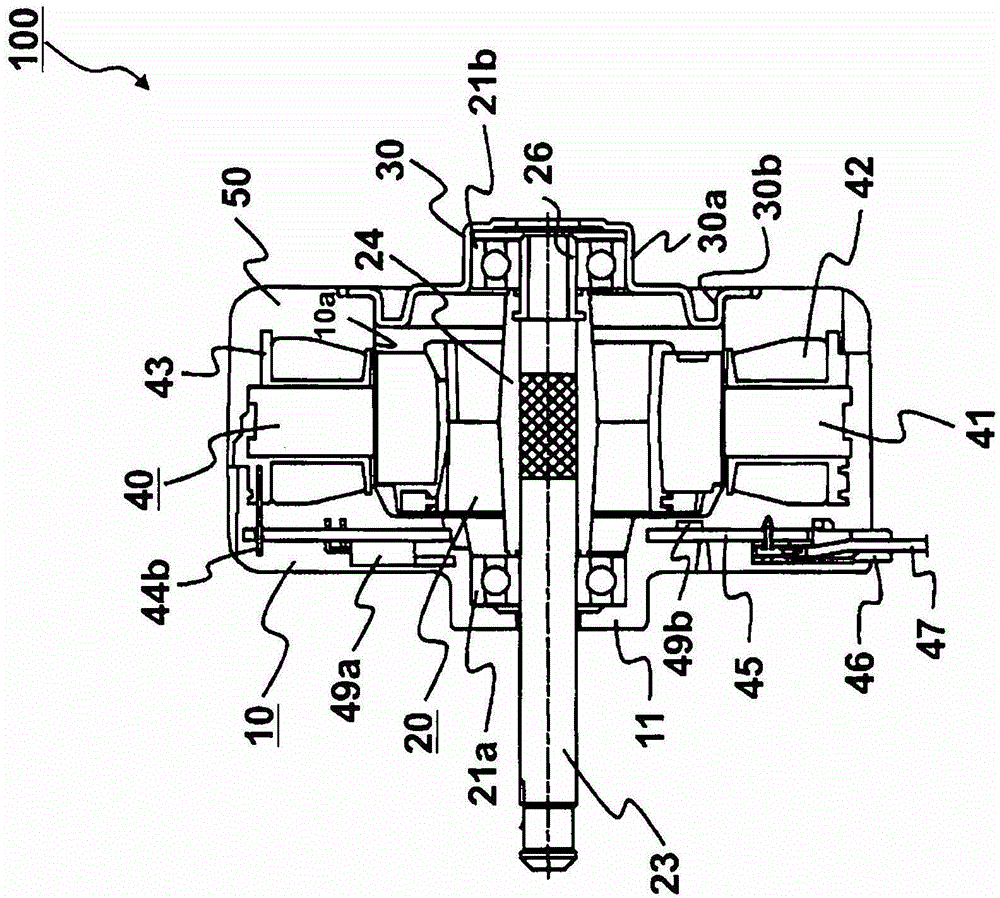

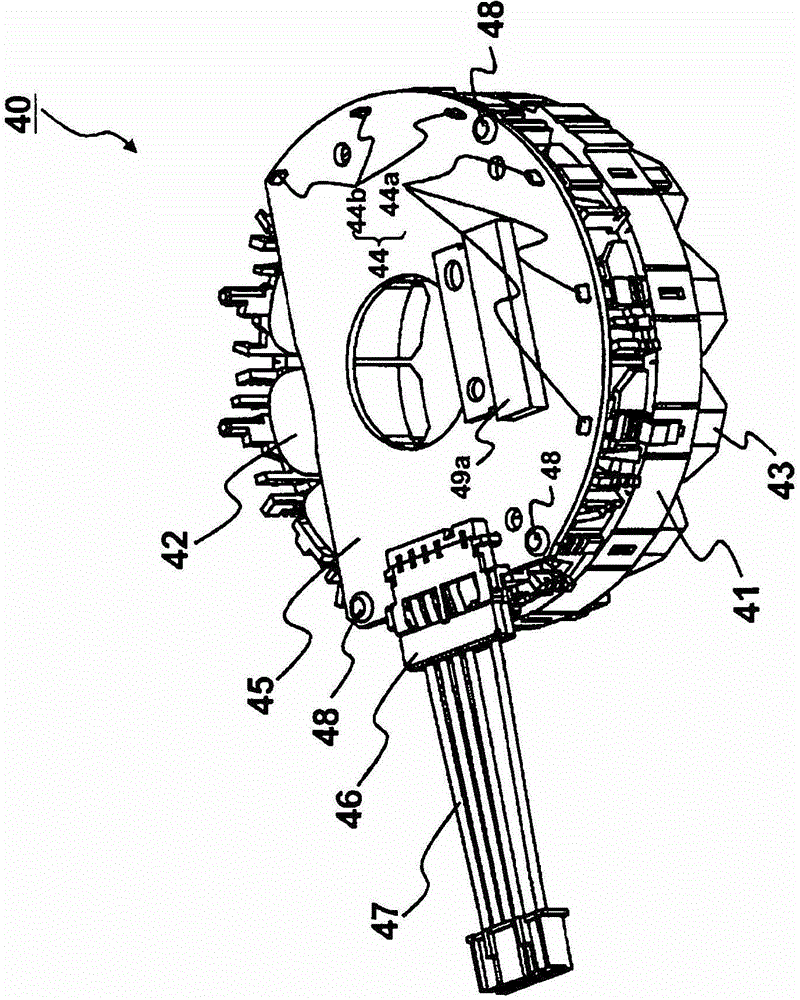

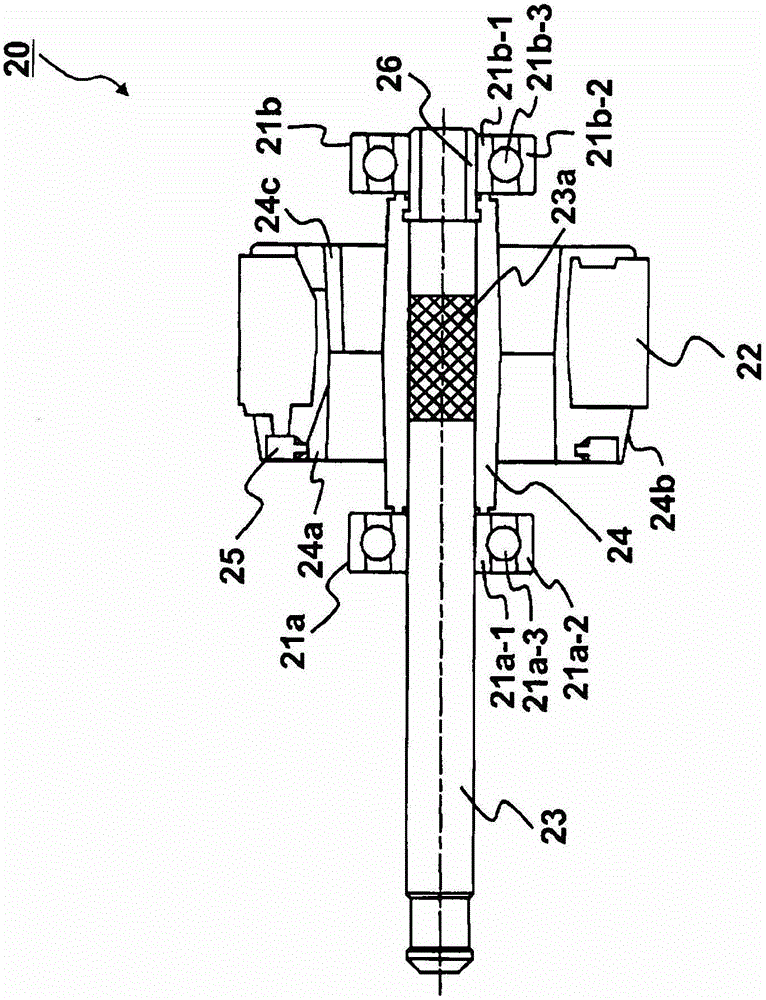

[0033] Figure 1 to Figure 14 is a diagram showing Embodiment 1, figure 1 is a cross-sectional view of the motor 100, figure 2 is a perspective view of the stator 40, image 3 is a cross-sectional view of the rotor 20, Figure 4 is an enlarged sectional view of the opposite-to-load side end of the shaft 23, Figure 5 is a diagram showing the insulating sleeve 26 ((a) is a front view, (b) is a side view), Image 6 It is a figure which shows the resin magnet 22 of a rotor ((a) is a left side view, (b) is A-A cross-sectional view of (a), (c) is a right side view), Figure 7 It is a diagram showing the resin magnet 25 for position detection ((a) is a left side view, (b) is a front view, and (c) is an enlarged view of part A of (b)), Figure 8 is a cross-sectional view of the rotor 20 of Modification 1, Figure 9 is a cross-sectional view of the rotor 20 of Modification 2, Figure 10 is a front view of the insulating sleeve 26 used in the rotor 20 of Modification 2, Figur...

Embodiment approach 2

[0140] Figure 15 It is a figure which shows Embodiment 2, and is a structural figure of the air conditioner 300. FIG.

[0141] The air conditioner 300 includes an indoor unit 310 and an outdoor unit 320 connected to the indoor unit 310 . An indoor unit blower (not shown) is mounted on the indoor unit 310 , and an outdoor unit blower 330 is mounted on the outdoor unit 320 .

[0142] Furthermore, the air blower 330 for an outdoor unit and the air blower for an indoor unit are provided with the electric motor 100 of Embodiment 1 mentioned above as a drive source.

[0143] The durability of the air conditioner 300 is improved by mounting the electric motor 100 according to Embodiment 1 on the outdoor unit blower 330 and the indoor unit blower which are main components of the air conditioner 300 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com