Wet-type cloth bag deep dedusting system

A dust removal system, wet dust removal technology, applied in the separation method, lighting and heating equipment, dispersed particle separation, etc., can solve the problems of bag damage, affecting economic benefits, poor dust removal effect, etc., and achieve low working temperature and high reliability , to avoid the effect of acid corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

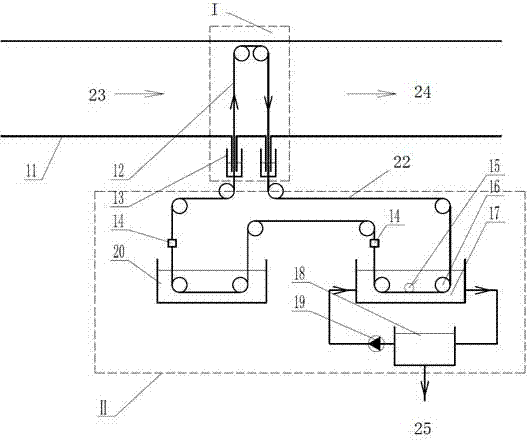

[0033] The present invention is described in detail below in conjunction with accompanying drawing:

[0034] The present invention consists of wet dedusting system I and cleaning and alkaline regeneration system II. The two constitute a closed system, namely: the inlet end of the cloth bag I 12 of the wet dust removal system I is connected to the outlet end of the cloth bag II 22 of the cleaning and regeneration system II, and the outlet end of the cloth bag I 12 of the wet dust removal system I is connected to the cleaning and regeneration system II. The cloth bag II 22 of the regeneration system II is connected at the inlet end, and the cloth bag I 12 and the cloth bag II 22 are connected and circulated into the flue 11 under the action of the transmission wheel 16 .

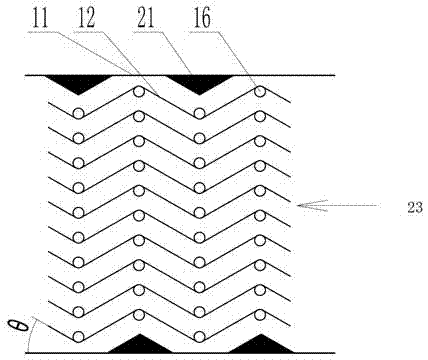

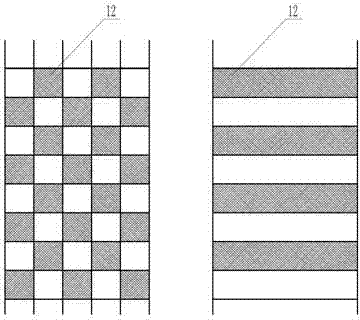

[0035] The wet dust removal system I consists of a cloth bag I 12, a transmission wheel 16 and a water seal 14; the cloth bag I 12 is driven by the transmission wheel 16 at a slow speed, enters from one side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com