Preparation method of modified whey protein gel

A technology of whey protein gel and whey protein, which is applied in the processing of animal protein and can solve the problems of high energy consumption and long processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

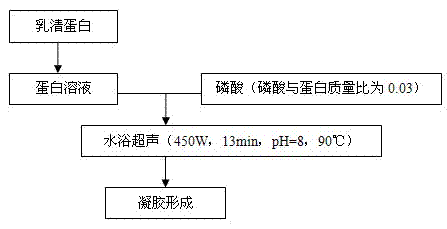

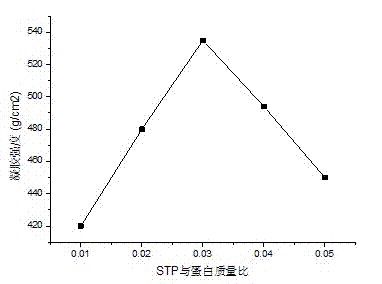

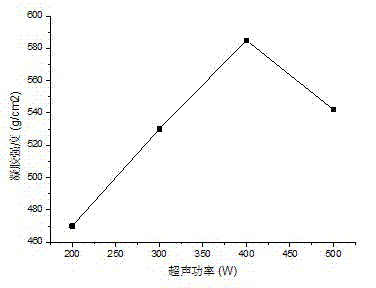

[0021] A method for preparing a modified whey protein gel, the method comprising the following steps: (1) dissolving whey protein in water to form a 15% protein solution; (2) adding a certain amount of Phosphoric acid, the mass ratio of phosphoric acid to protein is 0.01-0.05; (3) Place the phosphoric acid-treated protein solution in a 90°C water bath to heat, while adjusting the pH of the solution to 8, and perform ultrasonic treatment. The ultrasonic power is 200-500W, ultrasonic time is 5-20min, whey protein gel will be formed after ultrasonic treatment.

[0022] The preferred ratio of phosphoric acid to protein is 0.03.

[0023] The preferred parameters of the ultrasonic treatment are: ultrasonic power 450W, ultrasonic time 13min.

[0024]

experiment example

[0025] Experimental example Screening experiment of phosphoric acid addition amount and optimal parameters of ultrasonic process conditions

[0026] 1 Materials and methods

[0027] 1.1 Materials and reagents

[0028] Whey Protein Hargaco

[0029] Sodium tripolyphosphate Suzhou Jinlian Chemical Co., Ltd.

[0030] 1.2 Main instruments and equipment

[0031] TA Texture Analyzer SMS UK

[0032] pHS-25 acidity meter Shanghai Weiye Instrument Factory

[0033] Electronic Analytical Balance Merlot-Toledo Instruments (Shanghai) Co., Ltd.

[0034] Precision Electric Mixer Jiangsu Jintan City Ronghua Instrument Manufacturing Co., Ltd.

[0035] Ultrasonic Cleaner Yuyao Dongfang Electrical Instrument Factory

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com