Automatic seedling raising seedbed

A seedbed and seedling tray technology, applied in the field of mechanized seedling raising equipment, can solve the problems of burning dead seedlings, a large number of sprocket groups, densely arranged seedling trays, etc., and achieves the effects of reducing labor intensity, uniform light receiving area, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

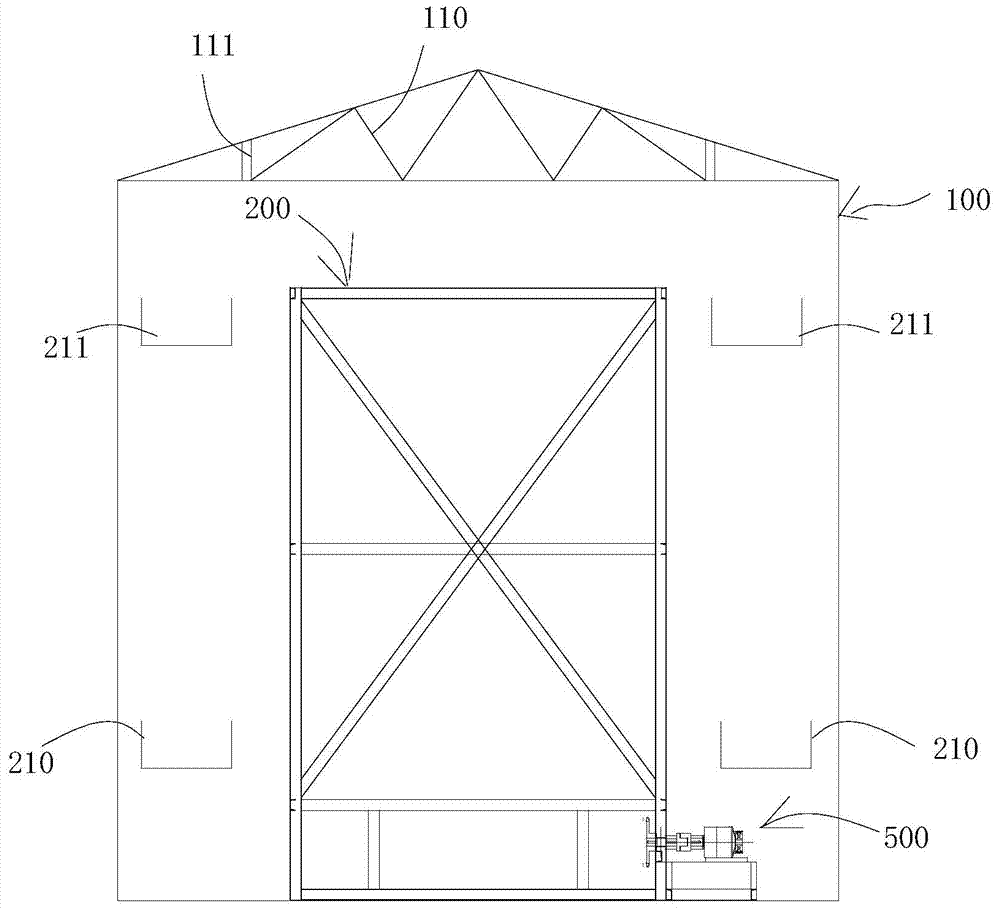

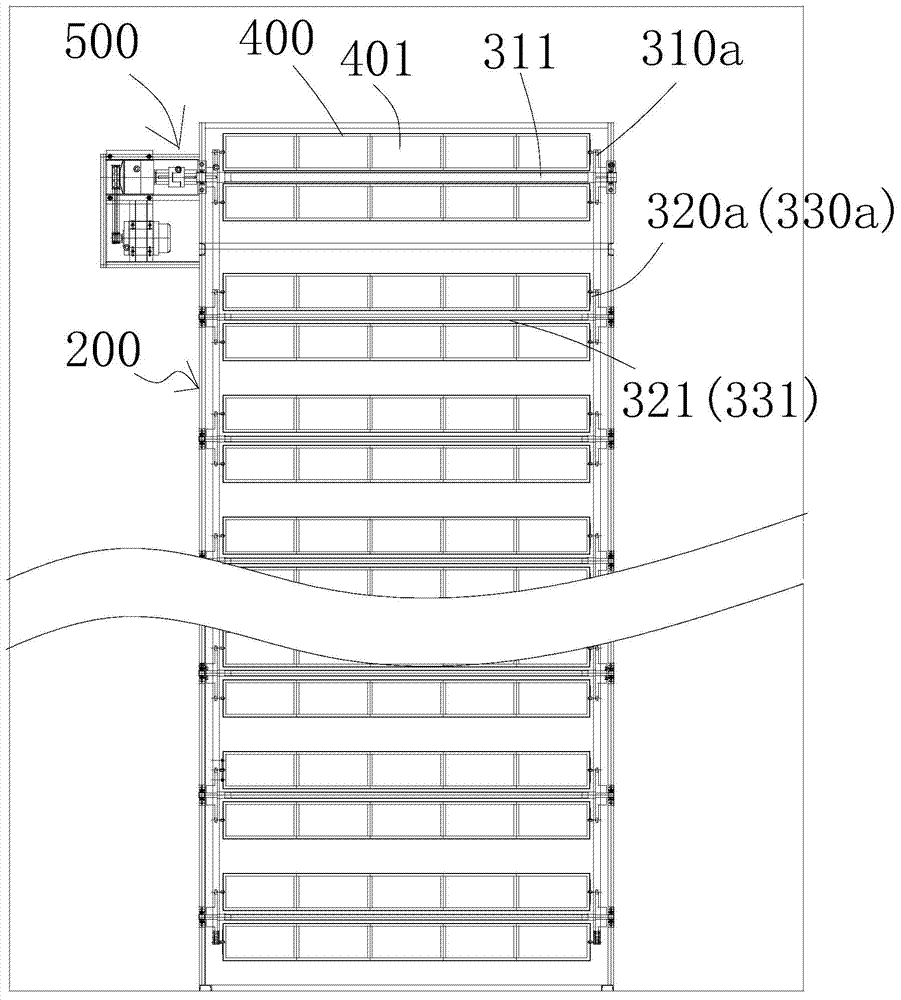

[0051] see Figure 1 to Figure 6 As shown, the automatic seedling raising bed includes a steel structure PC sunshine panel house 100 and a seedling raising bed arranged in parallel in the steel structure PC sunshine panel room along the length direction of the steel structure PC sunshine panel room. Certainly, the seedling raising seedling bed can be two or Two or more.

[0052] Front and rear electric doors 102 ( Figure 6 shown in ), the front and rear walls except the electric door 102 are covered with fixed windows and transparent sunlight panels, and the steel structure PC sunlight panel house 100 is folded with multi-section fully opened and segmented transparent sunlight panels with electric window pages 130 ( Figure 6 shown in ), of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com