Fully-automatic horizontally-circular seedling breeding system

A fully automatic, horizontal technology, applied in greenhouse cultivation, climate change adaptation, horticulture, etc., can solve the problems of small number of seedling trays and low space utilization rate, achieve uniform light receiving area, improve space utilization rate, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

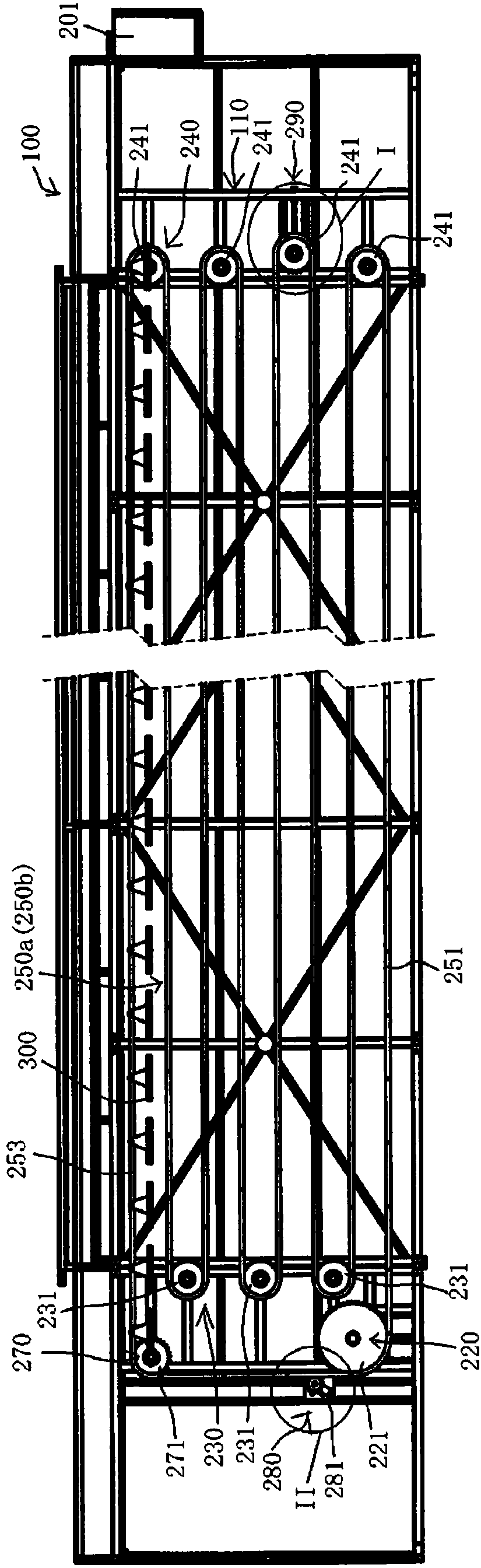

[0036] see figure 1As shown, the fully automatic horizontal circulation seedling raising system includes a seedling raising room 100 built by a skeleton and transparent materials and a horizontal circulation seedling raising device 200 arranged in the seedling raising room 100. One side of the seedling raising room 100 is provided with a seedling room door (not shown in the figure). out).

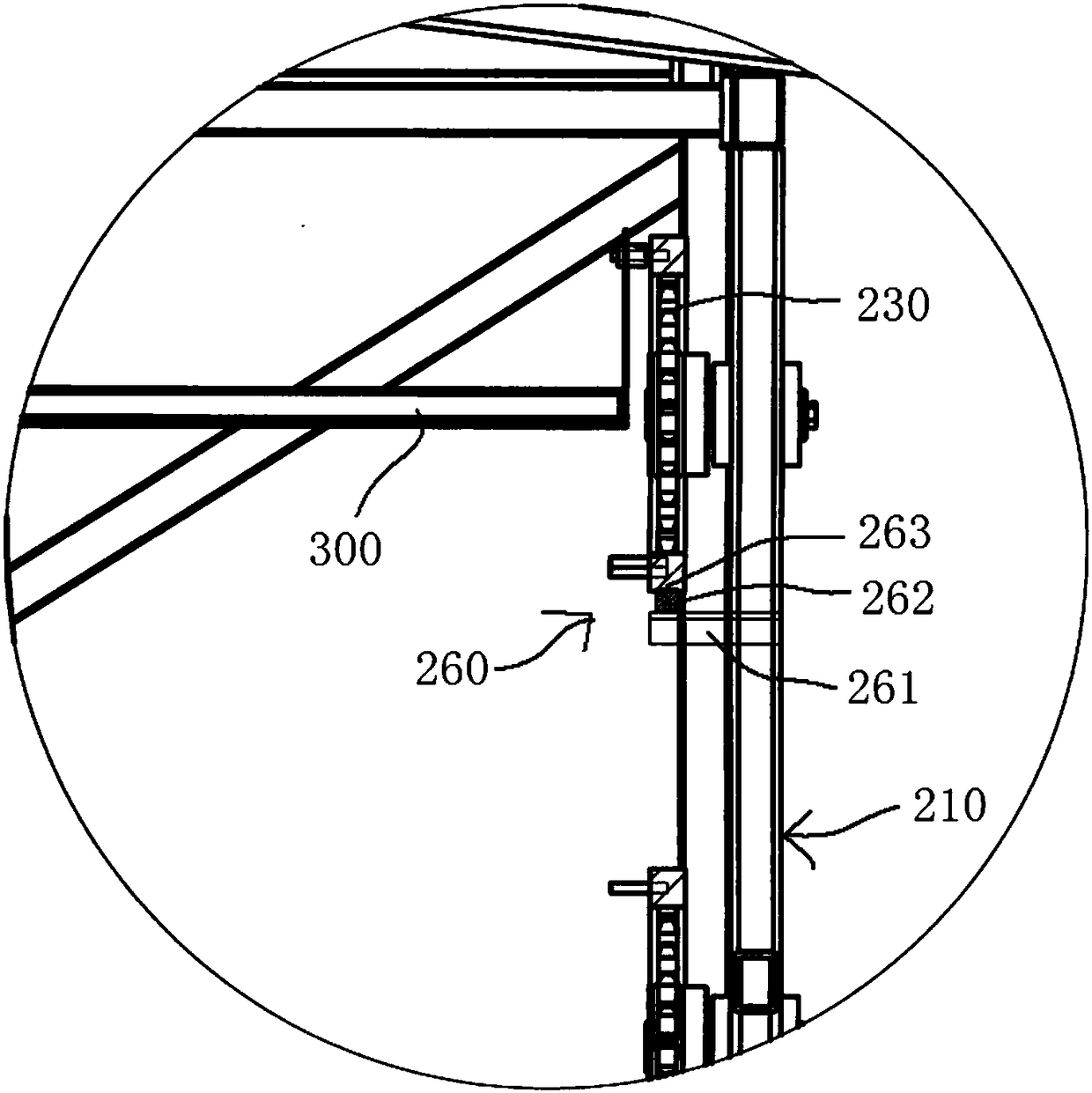

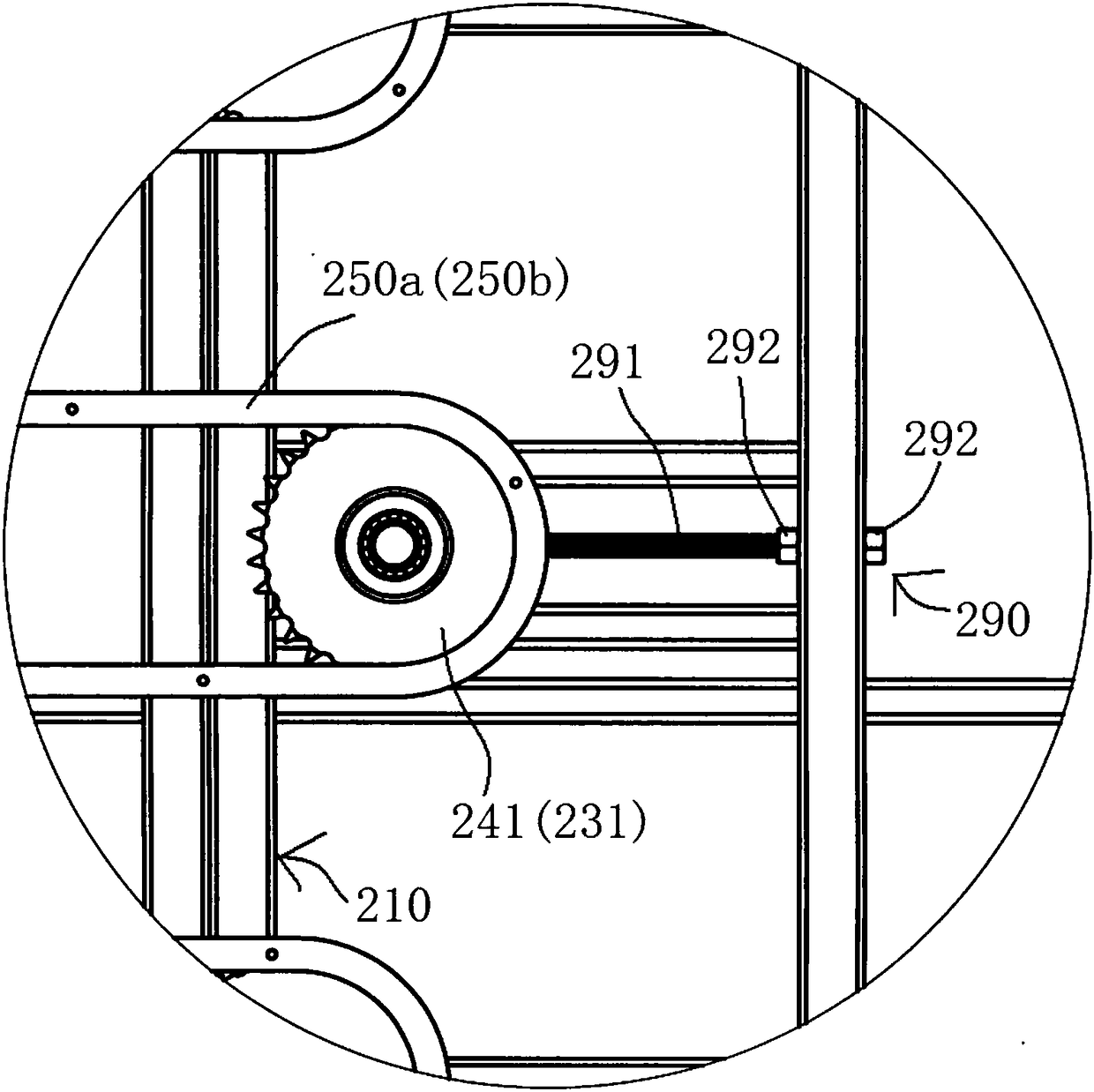

[0037] The circular seedling raising device 200 includes a three-dimensional seedling rack 210, a driving sprocket set 220, some first side sprocket sets 230, some second side sprocket sets 240, a first chain 250a, a second chain 250b, and several seedling trays. Basket 300 and drive unit (not shown in the figure), the seedling disc inlet and outlet end of v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com