Rubber composition for tread, and pneumatic tire

A rubber composition, rubber technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problem of handling stability (deterioration of handling performance, difficulty in balancing wet grip performance and processability, reduced grip performance) and other problems, to achieve the effect of improving wet grip performance, improving handling stability, and excellent performance balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

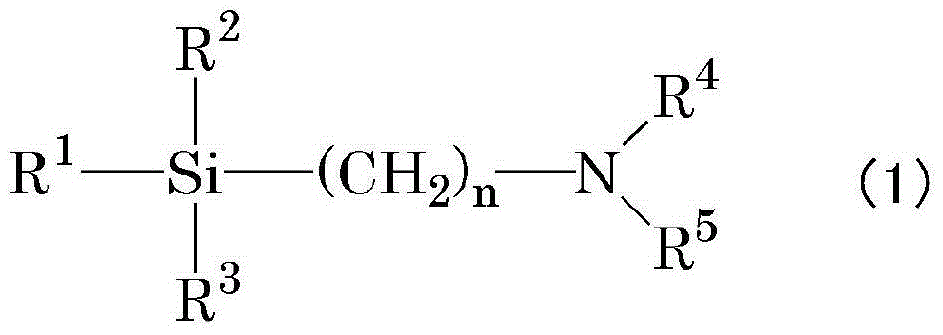

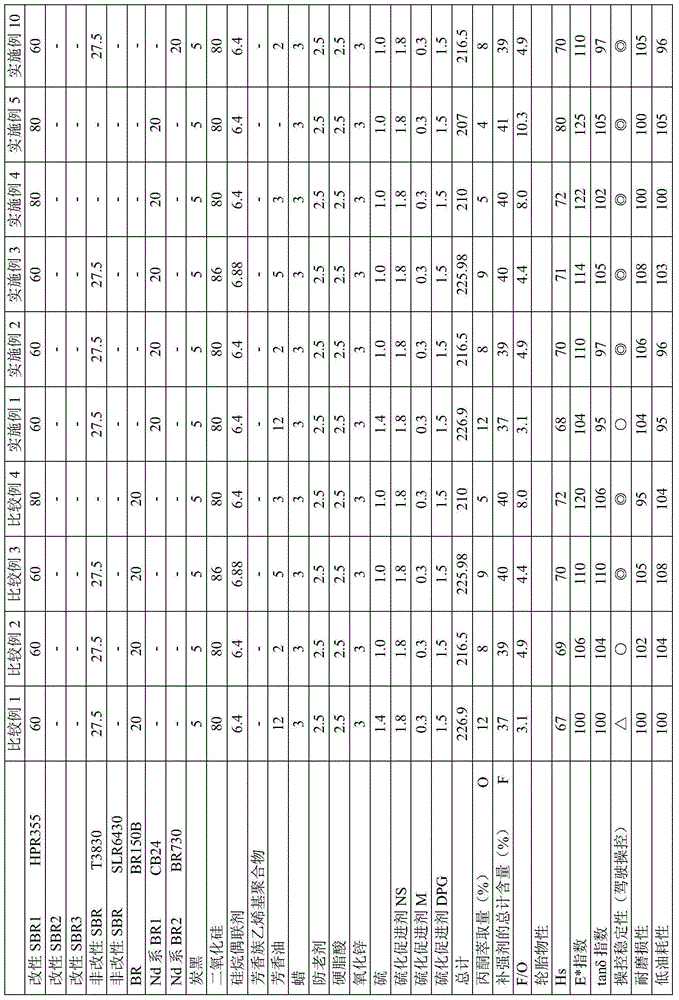

[0022] The rubber composition for treads of the present invention contains: terminal-modified solution-polymerized styrene-butadiene rubber (hereinafter, also referred to as "modified SBR"), butadiene rubber synthesized using a rare earth element-based catalyst (hereinafter, , also known as "rare earth BR") and reinforcing agent.

[0023] By using modified SBR and rare earth BR in combination with a reinforcing agent, the balance of handling stability (handling performance), wear resistance, and low fuel consumption can be improved, and the balance of these properties can be synergistically improved. In addition, by further blending SBR with a specific Mw with a high styrene content, the wet grip performance can be improved without deteriorating the fuel economy, and in addition to the handling stability, wear resistance, and fuel economy, it is also Improved wet grip performance can be balanced well. On the other hand, although there is a concern that the kneading processabi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com