Transmission unit with planetary gearing system

A technology for planetary gears and transmissions, applied in belts/chains/gears, vehicle gearboxes, bicycle accessories, etc., which can solve problems such as unrealized deployment length, hindering planetary gear transmission tooth meshing, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

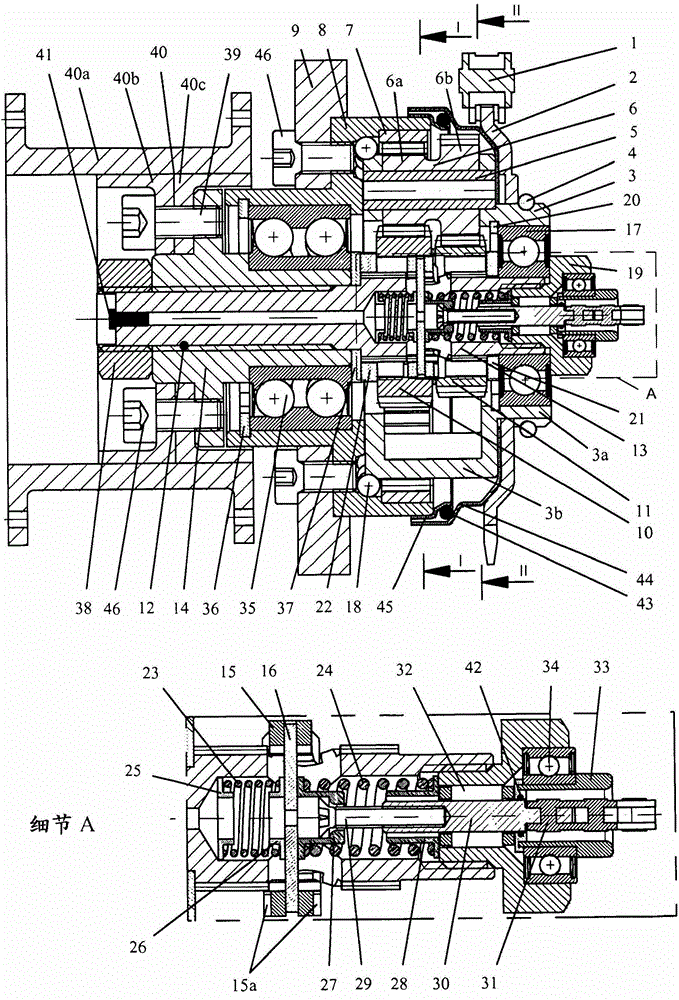

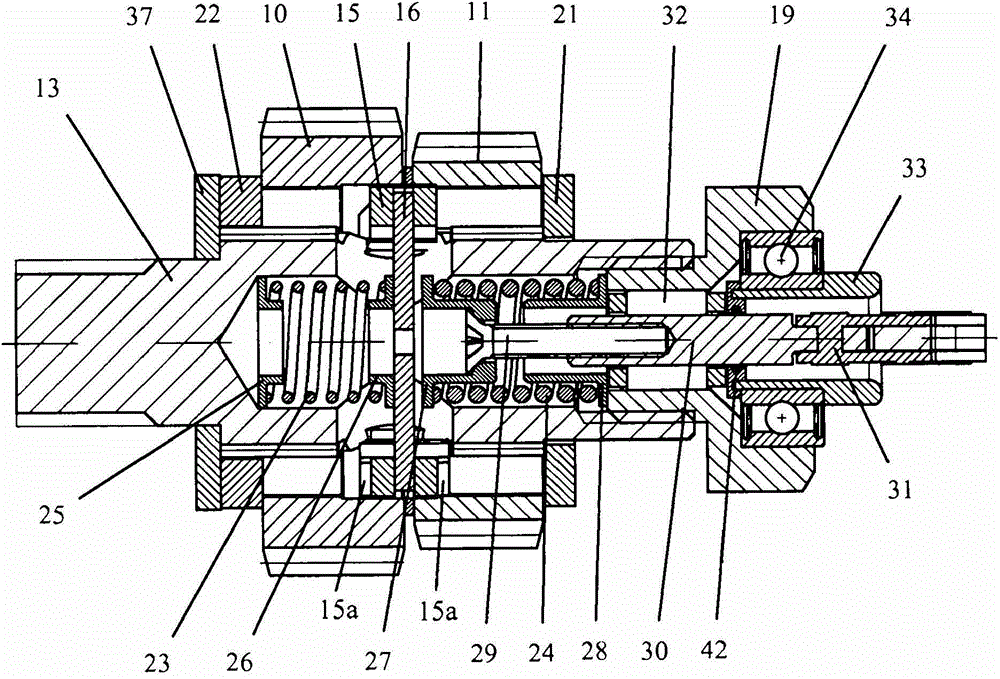

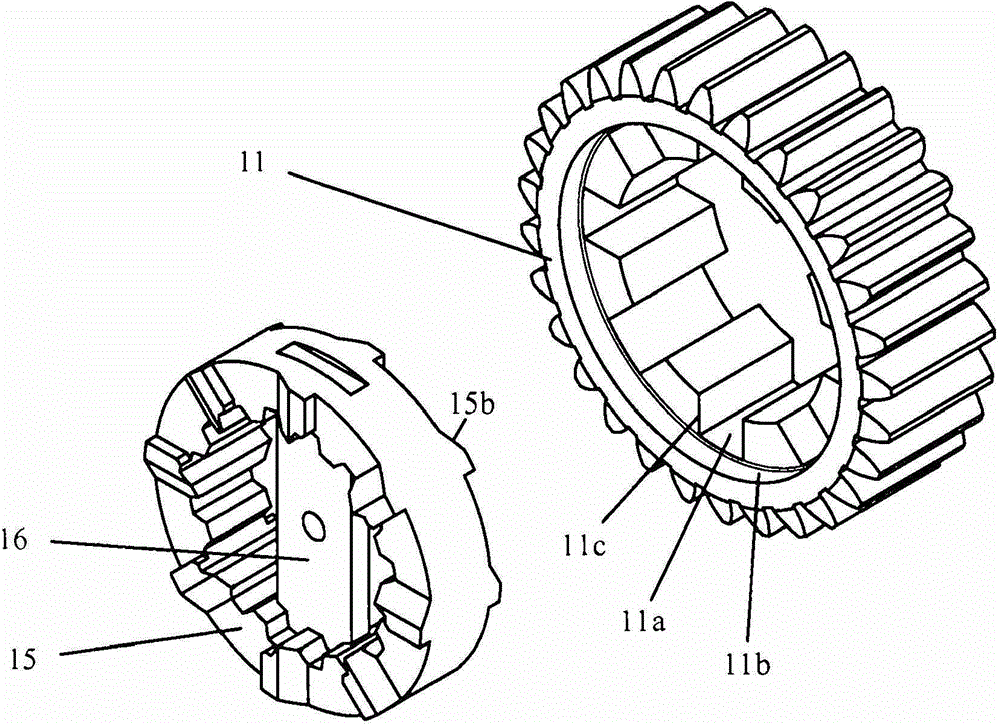

[0052] V-belts or toothed belts connected to a continuous chain drive or a continuous belt drive preceding a variator unit or connected to a spur gear drive preceding a variator unit, shown either by a chain 1 or not separately or not separately The driven wheel 2 driven by the spur gear is operatively connected in relative rotation to the drive 3 of the transmission unit via a shaft-hub connection, wherein the driven wheel 2 is fastened to the drive 3 , for example by means of a safety ring 4 . The driver 3 driven by the driven wheel 2 comprises a driver part 3a and is formed as a planetary carrier 3b of a planetary gearing, viewed axially towards the bicycle frame, according to a particular feature of the invention.

[0053] According to a particular feature of the invention, the driven wheel 2 and the planetary carrier 3b are located axially outside the bicycle frame. This enables installation and removal of the chain 1 without having to remove the rear wheel at the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com