Simulation method for carbon dioxide flooding simulation experiment of planar five-point well pattern in low permeability oilfield

A technology of carbon dioxide and simulation method, which is applied in the direction of earthwork drilling and production, wellbore/well components, etc., and can solve the problems that the simulation method is not suitable for carbon dioxide flooding simulation in low permeability oilfields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

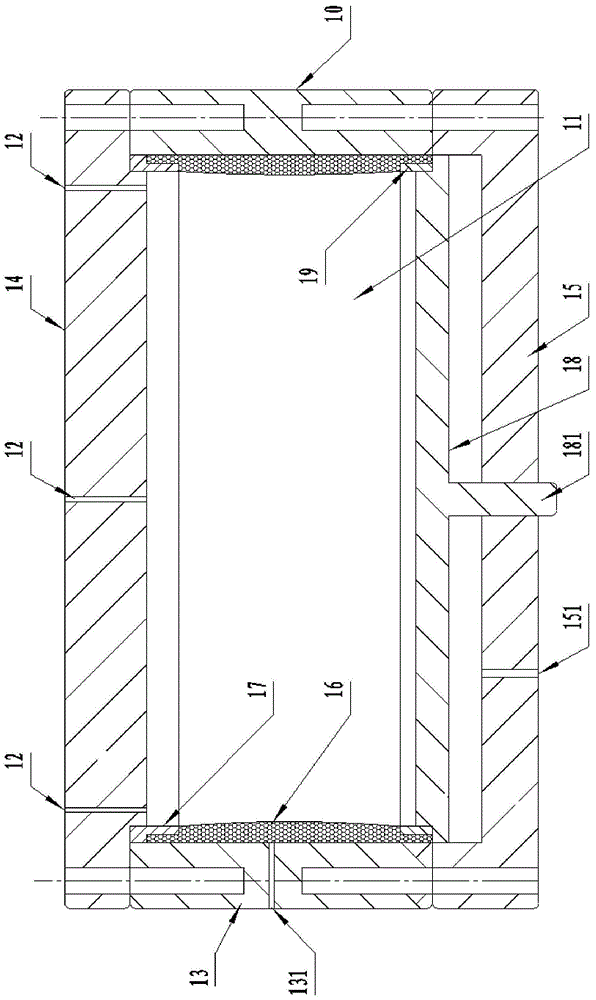

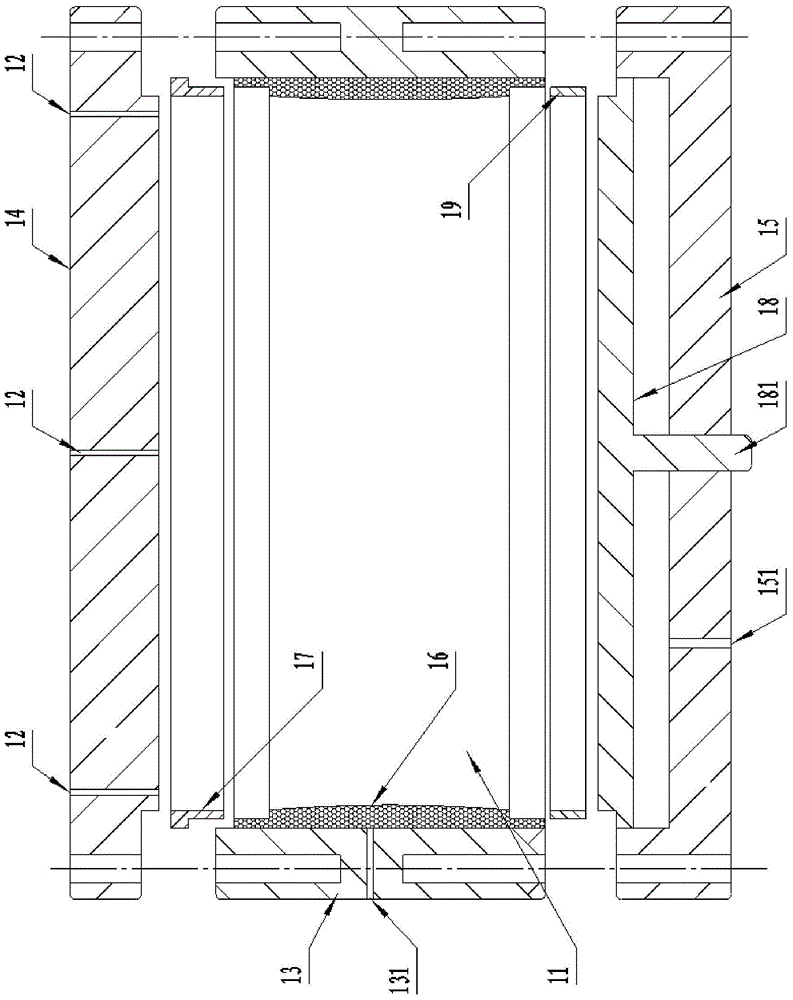

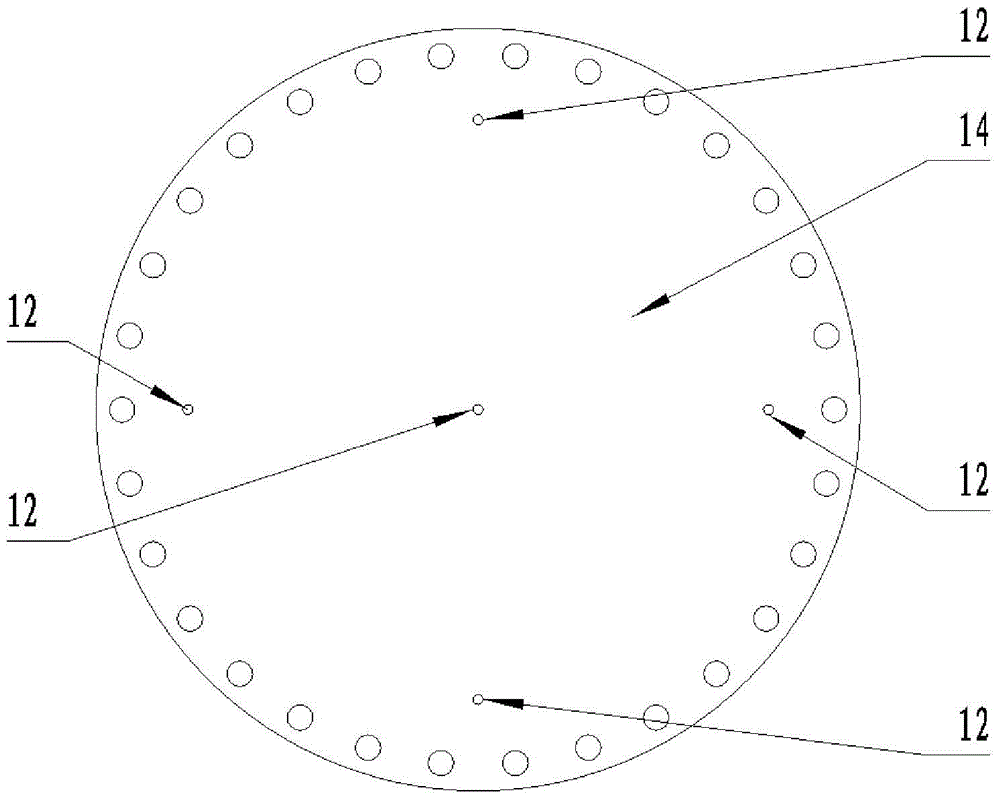

[0070] It is a simulation experiment method of carbon dioxide constant pressure flooding with planar five-point well pattern in homogeneous low-permeability oil fields, including the following steps:

[0071] Step 1: Select a core and drill five blind holes on the surface of the core corresponding to the five through holes 12 on the holder 10 for planar five-point well pattern simulation; specifically, it includes:

[0072] 1.1. Choose natural core or artificial core, sand the core with sandpaper or electric saw to ensure that the surface of the core is flat, and the size is moderate, and it can be loaded into the holder.

[0073] 1.2. Coat the surface of the core uniformly with a thickness of about 0.2-0.4mm, and then place it in an oven to dry the coating. The recommended coating method in this method is to use a doctor blade along a single direction to apply the resin on the core surface side by side. Shave well.

[0074] 1.3. Drilling is performed on the upper surface of the core,...

Embodiment 2

[0098] It is a simulation experiment method of flat five-point well pattern carbon dioxide constant flow displacement in homogeneous low-permeability oil fields, including the following steps:

[0099] Step 1: Select a core and drill five blind holes on the surface of the core that correspond to the five through holes (12) on the holder (10) for the above-mentioned planar five-point well pattern simulation;

[0100] Step 2: Load the core into the holder (10) for the above-mentioned planar five-point well pattern simulation;

[0101] Step 3: Inject water and crude oil into the core in the holder (10) for simulation of the planar five-point well pattern simulation to establish the irreducible water saturation;

[0102] Step 4: Inject fluid into the holder for simulation of the planar five-point well pattern through the above-mentioned gas injection device (31), and collect and measure experimental parameters through the above-mentioned produced fluid collection and calibration equipment ...

Embodiment 3

[0107] It is a simulation experiment method of carbon dioxide constant pressure flooding with planar five-point well pattern in fractured low-permeability oil fields, including the following steps:

[0108] Step 1: Select a core and drill five blind holes on the surface of the core that correspond to the five through holes (12) on the holder (10) for the above-mentioned planar five-point well pattern simulation;

[0109] Step 2: Load the core into the holder (10) for the above-mentioned planar five-point well pattern simulation;

[0110] Step 3: Inject water and crude oil into the core in the holder (10) for simulation of the planar five-point well pattern simulation to establish the irreducible water saturation;

[0111] The details of the above three steps are the same as steps 1 to 3 in Embodiment 1, and will not be repeated, except that step 4 is different. The following describes step 4 in this embodiment.

[0112] Step 4: Inject fluid into the holder for simulation of the planar f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com