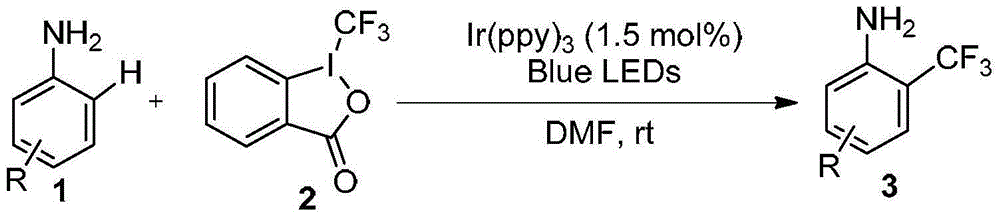

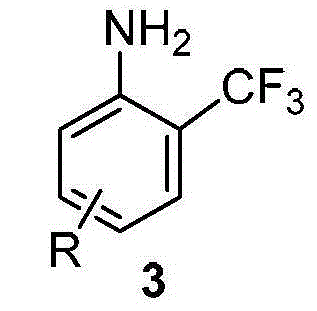

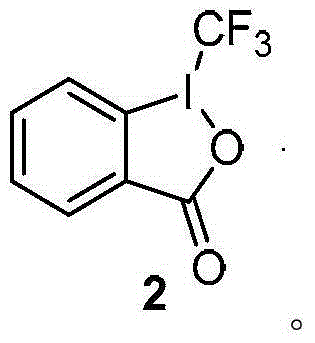

A method for preparing o-trifluoromethylaniline or derivatives thereof

A technology of trifluoromethylaniline and aniline derivatives, which is applied in the field of preparation of trifluoromethylaniline derivatives, can solve the problem of less trifluoromethylaniline, and achieve the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Under the protection of nitrogen or argon, 4-bromoaniline 0.4mmol, 0.2mmol, Ir(ppy) 3 (2 mg) and 1 ml of DMF were added to the reaction flask, and then irradiated with a blue LED light strip (7W) at room temperature until the trivalent iodine reagent was completely converted to complete the reaction. Add 10 mL of saturated Na 2 CO 3 aqueous solution, extracted 3 times with ethyl acetate, the organic layer was washed once with saturated brine, anhydrous Na 2 SO 4 Dry the organic layer. Column chromatography [200-300 mesh chromatography silica gel (the same below), eluent: petroleum ether 60-90: ethyl acetate = 20:1-10:1], to obtain the product Yield 61% (86% NMR yield). 1 HNMR (400MHz, CDCl 3 ):δ(ppm)=7.53(d,J=2.0Hz,1H),7.37(dd,J=8.8,2.0Hz,1H),6.63(d,J=8.0Hz,1H),3.86(s,2H ); 13 CNMR (100MHz, CDCl 3 ):δ(ppm)=143.5,135.6,129.2(q,J=5.5Hz),124.0(q,J=270.7Hz),110.8,115.2(q,J=30.9Hz); 19 FNMR (376MHz, CDCl 3 ):δ(ppm)=-63.2; HRMS(ESI)m / zcalcdforC 7 h 4 BrF 3 ...

Embodiment 2

[0022] Under the protection of nitrogen or argon, 4-iodoaniline 0.4mmol, 0.2mmol, Ir(ppy) 3 (2 mg) and 1 ml of DMF were added to the reaction flask, and then irradiated with a blue LED light strip (7W) at room temperature until the trivalent iodine reagent was completely converted to complete the reaction. Add 10 mL of saturated Na 2 CO 3 aqueous solution, extracted 3 times with ethyl acetate, the organic layer was washed once with saturated brine, anhydrous Na 2 SO 4 Dry the organic layer. Column chromatography (eluent: petroleum ether 60-90: ethyl acetate = 20:1-10:1) to obtain the product Yield 60%. 1 HNMR (400MHz, CDCl 3 ):δ(ppm)=7.68(d,J=1.6Hz,1H),7.52(dd,J=8.4,1.6Hz,1H),6.51(d,J=8.4Hz,1H),3.98(s,2H ); 13 CNMR (100MHz, CDCl 3 ):δ(ppm)=144.1,141.4,134.9(q,J=5.4Hz),123.8(q,J=271.3Hz),119.2,115.7(q,J=30.8Hz),77.4; 19 FNMR (376MHz, CDCl 3 ):δ(ppm)=-63.2; HRMS(ESI)m / zcalcdforC 7 h 4 f 3 IN[M-H] - :285.9346;found:285.9341.

Embodiment 3

[0024] Under the protection of nitrogen or argon, 0.4mmol, 0.2mmol, Ir(ppy) 3 (2 mg) and 1 ml of DMF were added to the reaction flask, and then irradiated with a blue LED light strip (7W) at room temperature until the trivalent iodine reagent was completely converted to complete the reaction. Add 10 mL of saturated Na 2 CO 3 aqueous solution, extracted three times with ethyl acetate, washed once with saturated brine, anhydrous Na 2 SO 4 Dry the organic layer. Column chromatography (eluent: petroleum ether 60-90: ethyl acetate = 15:1-8:1) to obtain the product Yield 67%. 1 HNMR (400MHz, CDCl 3 ):δ(ppm)=8.14(d,J=1.6Hz,1H),7.95(dd,J=8.4,1.6Hz,1H),6.73(d,J=8.4Hz),4.31(s,2H), 3.88(s,3H); 13 CNMR (100MHz, CDCl 3 ):δ(ppm)=166.2,148.3(d,J=1.8Hz),134.3,129.2(q,J=4.8Hz),124.5(q,J=271.2Hz),119.1,116.3,112.7(q,J =30.8Hz),51.9; 19 FNMR (376MHz, CDCl 3 ):δ(ppm)=-63.1; HRMS(ESI)m / zcalcdforC 9 h 7 f 3 NO 2 [M-H] - :218.0434;found:218.0449.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com