Loading jacking device for cartridge cases

A material top and bullet casing technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of slow processing, inability to realize multi-station work, etc., and achieve the effect of simple manufacturing and installation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

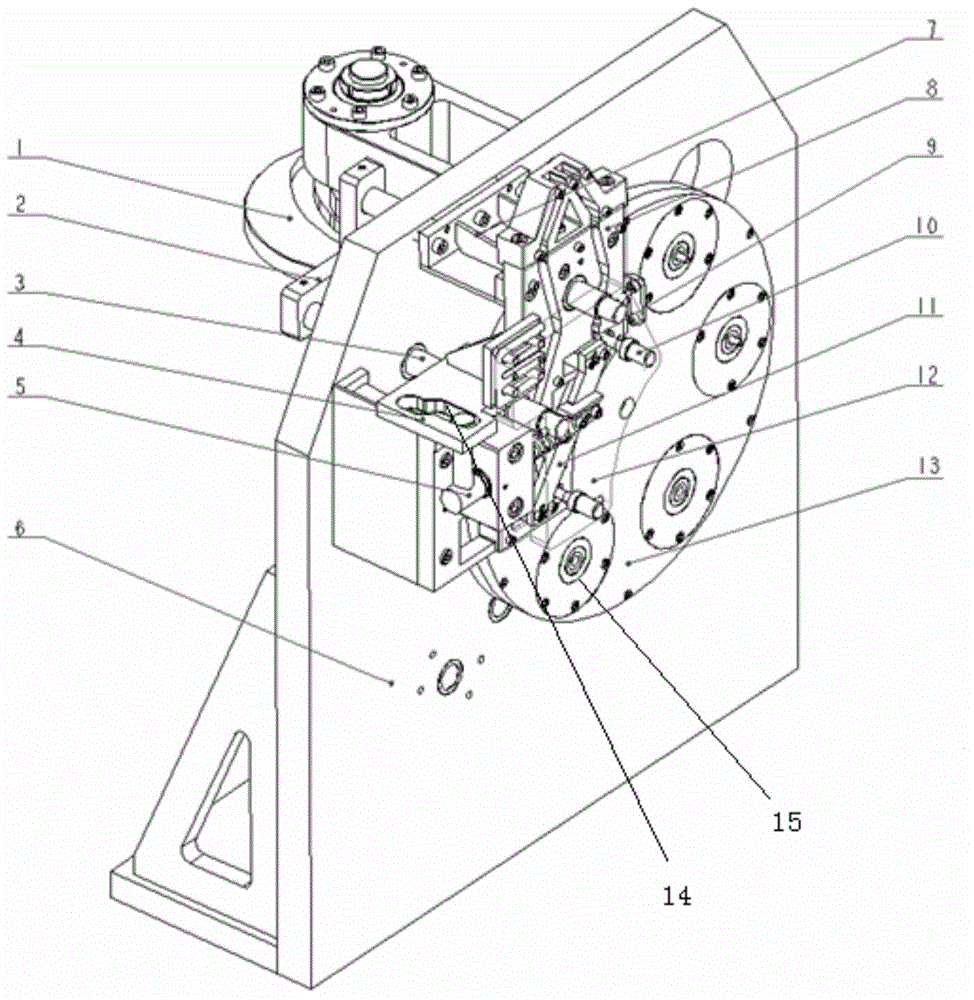

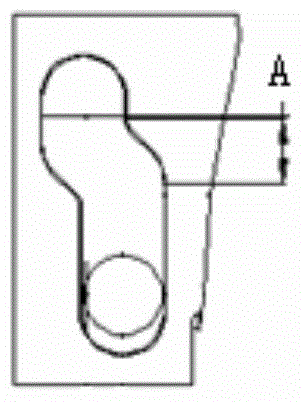

[0033] See Figure 1-2 As shown, a cartridge case loading and tightening device includes a cam 1, a connecting rod 2, a shaft 3, a guide bracket 4, a push rod 5, a support plate 6, a bracket 7, a slideway plate 8, claws 9, and a pressing rod 10 , the connection plate 11, the plate 12, and the rotary wheel 13 are characterized in that the connecting rod 2 is connected to the cam 1, one end of the shaft 3 is connected to the connecting rod 2, the other end of the shaft 3 is connected to the plate 12, and the guide bracket 4 is fixed on the plate 12 Above, the guide bracket 4 has a guide groove 14, the guide groove 14 is divided into a feeding stroke and a feeding stroke, one end of the push rod 5 is stuck in the guide groove 14 of the guide bracket 4, the other end of the push rod 5 is connected to the connecting plate 11, and the push rod 5 is connected to the connecting plate 11. The rod 10 is fixed on the plate 12, the claw 9 is fixed on the connecting plate 11, the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com