Transmission shaft thread processing positioning device

A thread processing and positioning device technology, which is applied in positioning devices, thread cutting devices, metal processing equipment, etc., can solve the problems of the overall positioning of the drive shaft and the angle of the thread that cannot meet the design requirements, and achieve the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

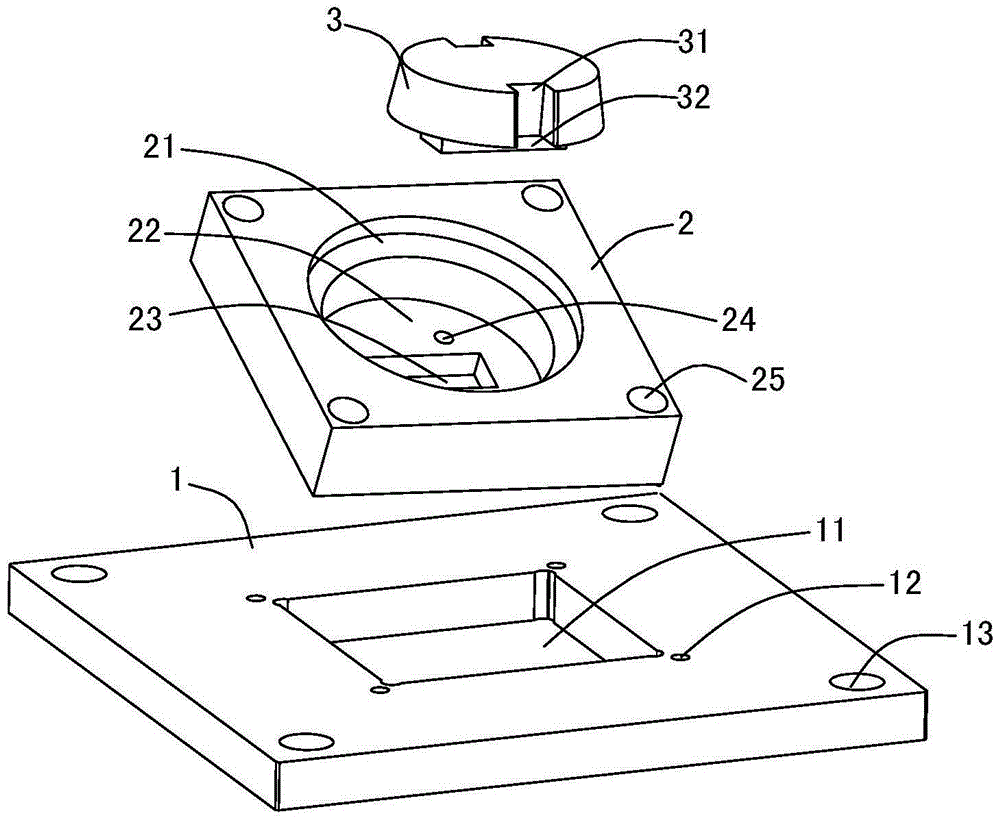

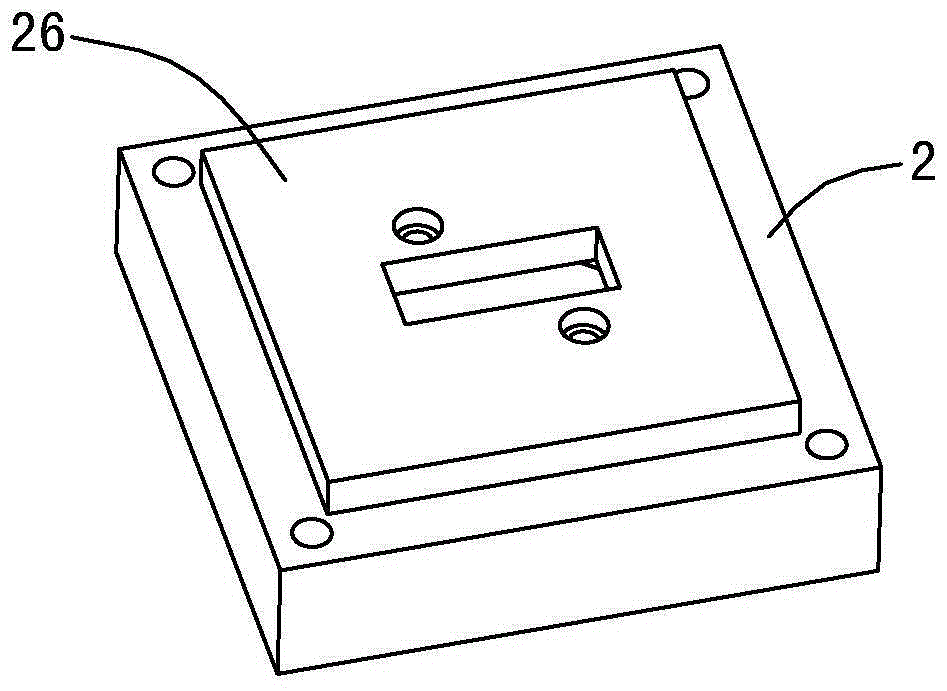

[0015] a kind of like Figure 1-2 The transmission shaft thread processing positioning device shown is used to process the thread of the small end of the transmission shaft, and it includes a base 1 that can be fixed on the machine table, and a clamp body 2 is detachably positioned on the base 1, and the clamp body 2 The bottom is provided with a first positioning block 26 matching the first positioning hole 11 on the base 1, and a cylindrical mold core 3 is detachably positioned on the clamp body 2, and the mold core 3 is placed on the In the second positioning hole 22 of the clamp body 2, a third positioning block 32 matching the third positioning hole 23 on the clamp body 2 is provided at the bottom of the mold core 3. The third positioning hole 23 passes through the first positioning block 26 and communicates with the second position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com