Engineering of thermotolerant bacillus coagulans for production of D(-)-lactic acid

一种基因、乳酸的技术,应用在制造D型乳酸的耐热凝结芽孢杆菌的基因工程领域,能够解决缺乏发酵等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

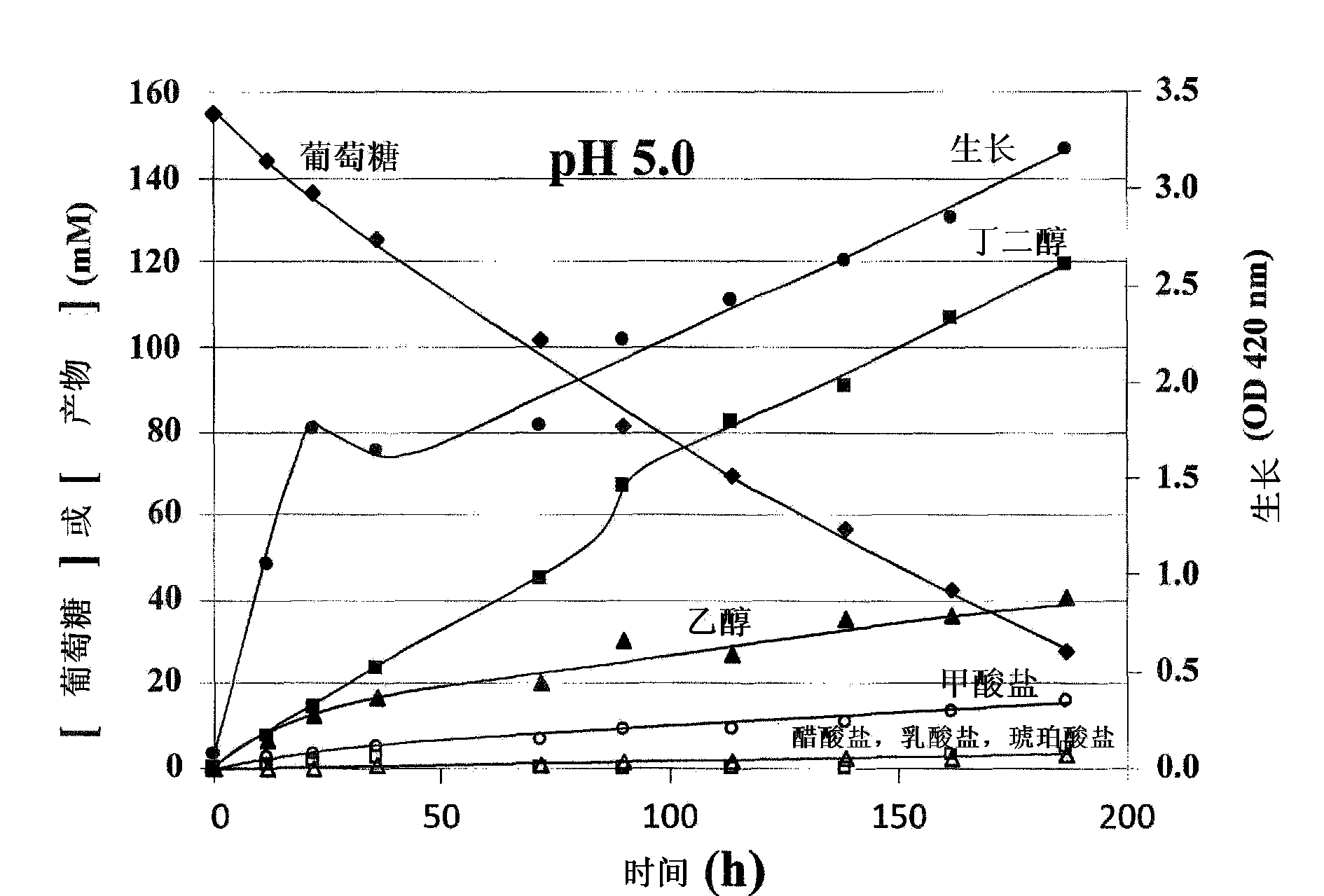

[0094] Example 1 - Construction of Bacillus coagulans that produces D-lactic acid and is resistant to heat

[0095] Raw materials and methods

[0096] Strains and plasmids

[0097] The prior art has been described for the Bacillus coagulans wild-type strain P4-102B (27). Escherichia coli strain Top10 (Invitrogen) and Bacillus subtilis strain HB1000 (11) were used as hosts during the construction of the various plasmids used in this study. Plasmid pGK12 carries chloramphenicol and erythromycin resistance genes and replicates in several Gram-positive bacteria and E. coli (17, 21). Although this plasmid has a broad host range, its replication is inherently restricted to temperature conditions ≤42°C. Due to the temperature-sensitive nature of plasmid pGK12 replication at 50°C, this provides an opportunity to screen for Bacillus coagulans with chromosomal DNA insertions that can grow at temperatures ranging from 50°C to 55°C. Plasmid pGK12 and its derivatives were maintaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com