Hydraulic support side thrust mechanism, hydraulic support and fully mechanized mining equipment

A technology of hydraulic support and side guard plate is applied in the field of side thrust mechanism, hydraulic support and fully mechanized mining equipment, which can solve the problems of high implementation cost, long time consumption and high difficulty of operation of side thrust jack, and reduce the time for disassembly and assembly and the implementation cost. , The effect of simplifying the production process and cost, and improving the efficiency of disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

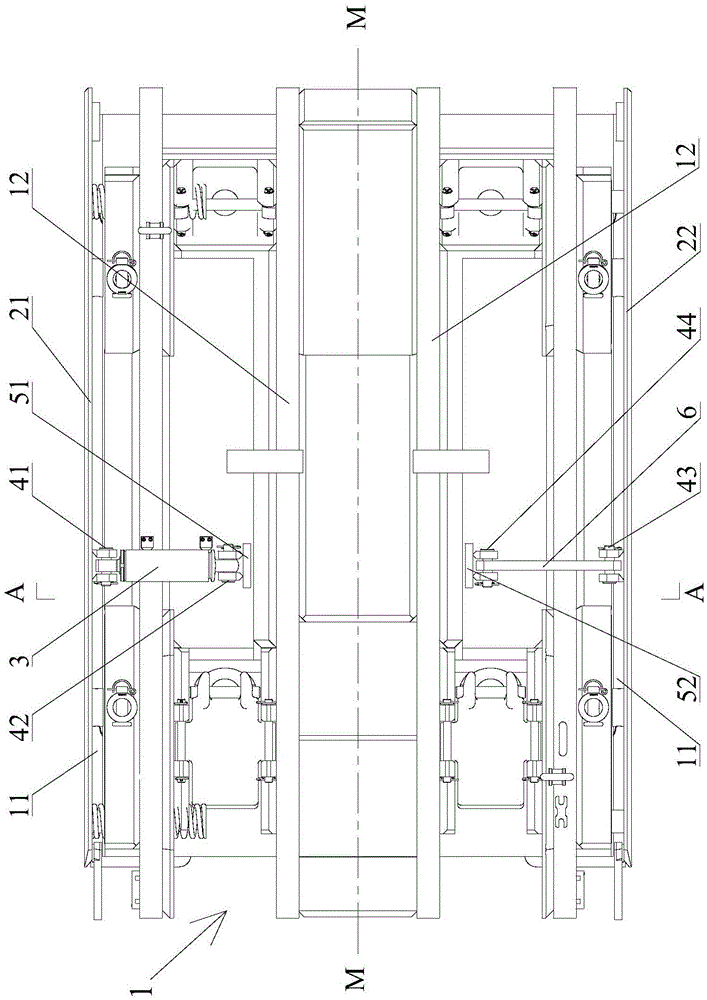

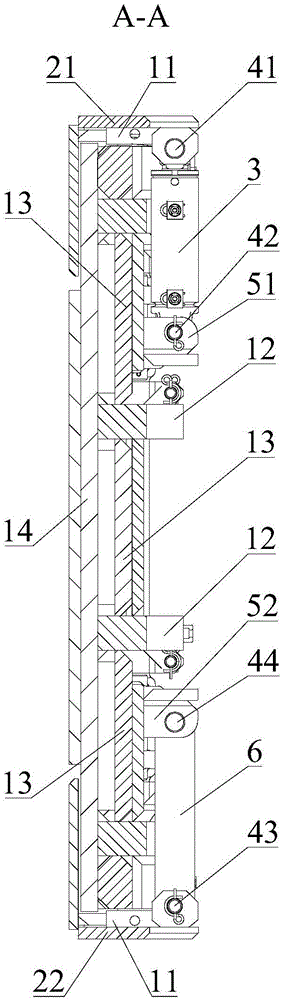

[0023] see figure 1 and figure 2 , shows the structure of the side pushing mechanism of the hydraulic support provided by the first embodiment of the present invention.

[0024] It can be seen from the figure that the hydraulic support includes a beam body 1, and the beam body 1 can be the main structure of the top beam of the hydraulic support, or can be the main structure of the cover beam of the hydraulic support. The beam body 1 can adopt a known structure, which mainly includes a top plate 14, a cover plate 13, and two outer main ribs 11 and two inner main ribs 12 respectively connected to the top plate 14 and the cover plate 13.

[0025] The side push mechanism of the hydraulic suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com