Dynamic mixer

A dynamic mixer and dynamic technology, applied in the direction of fluid mixer, mixer, mixer with rotary stirring device, etc., can solve the problems of unwanted generation and disadvantage, and achieve the reduction of waste share, filling amount, and reduction The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

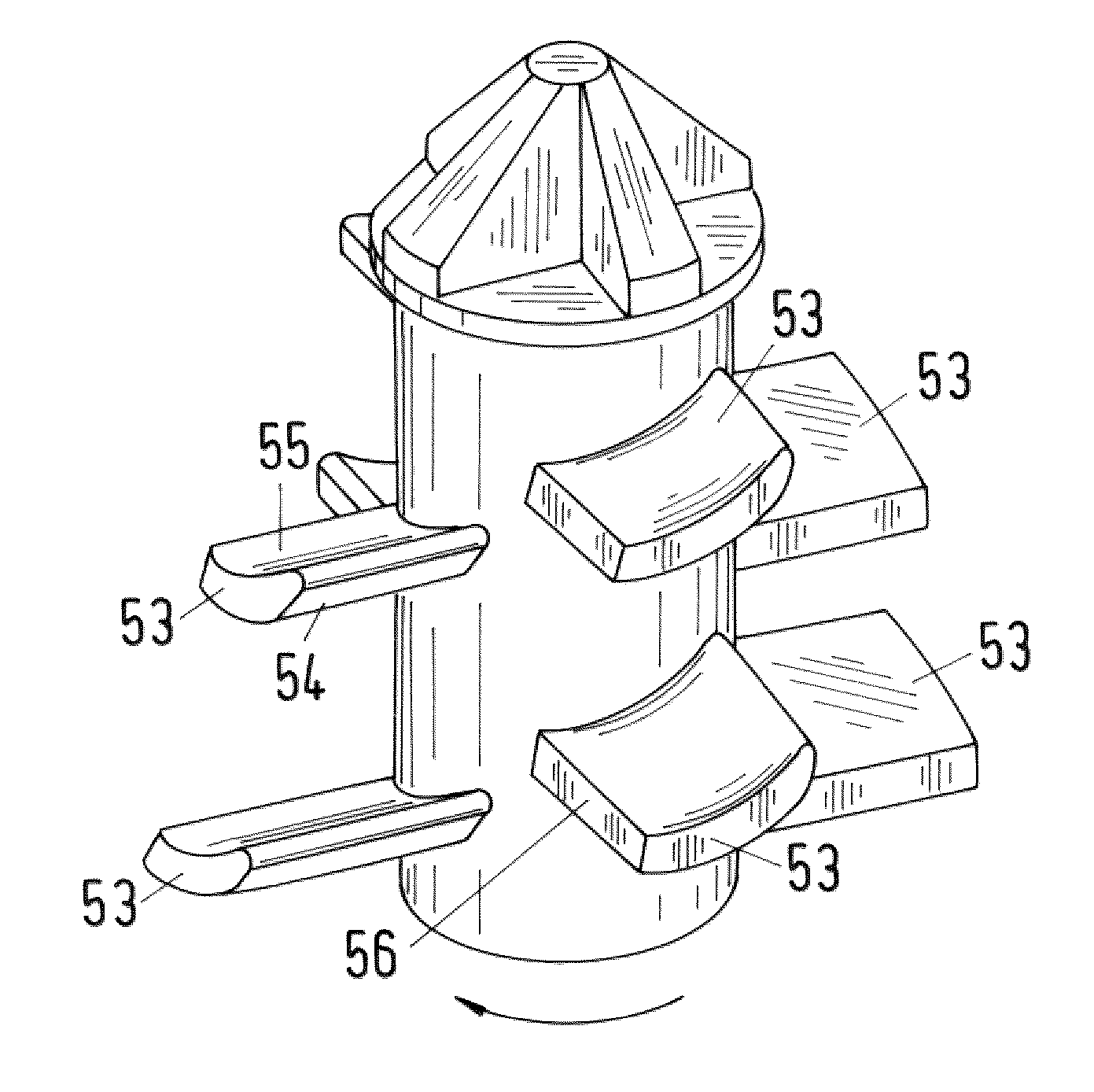

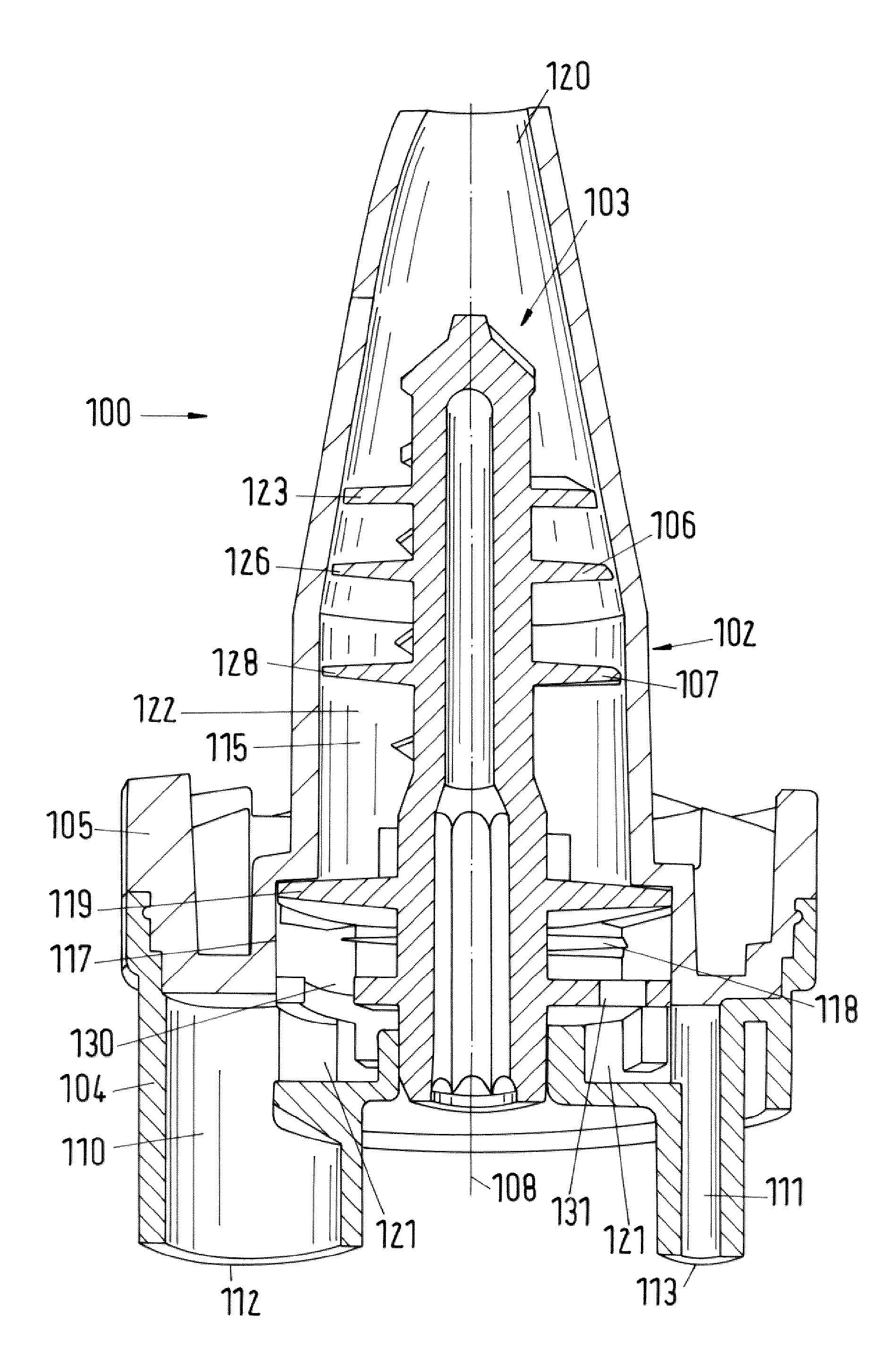

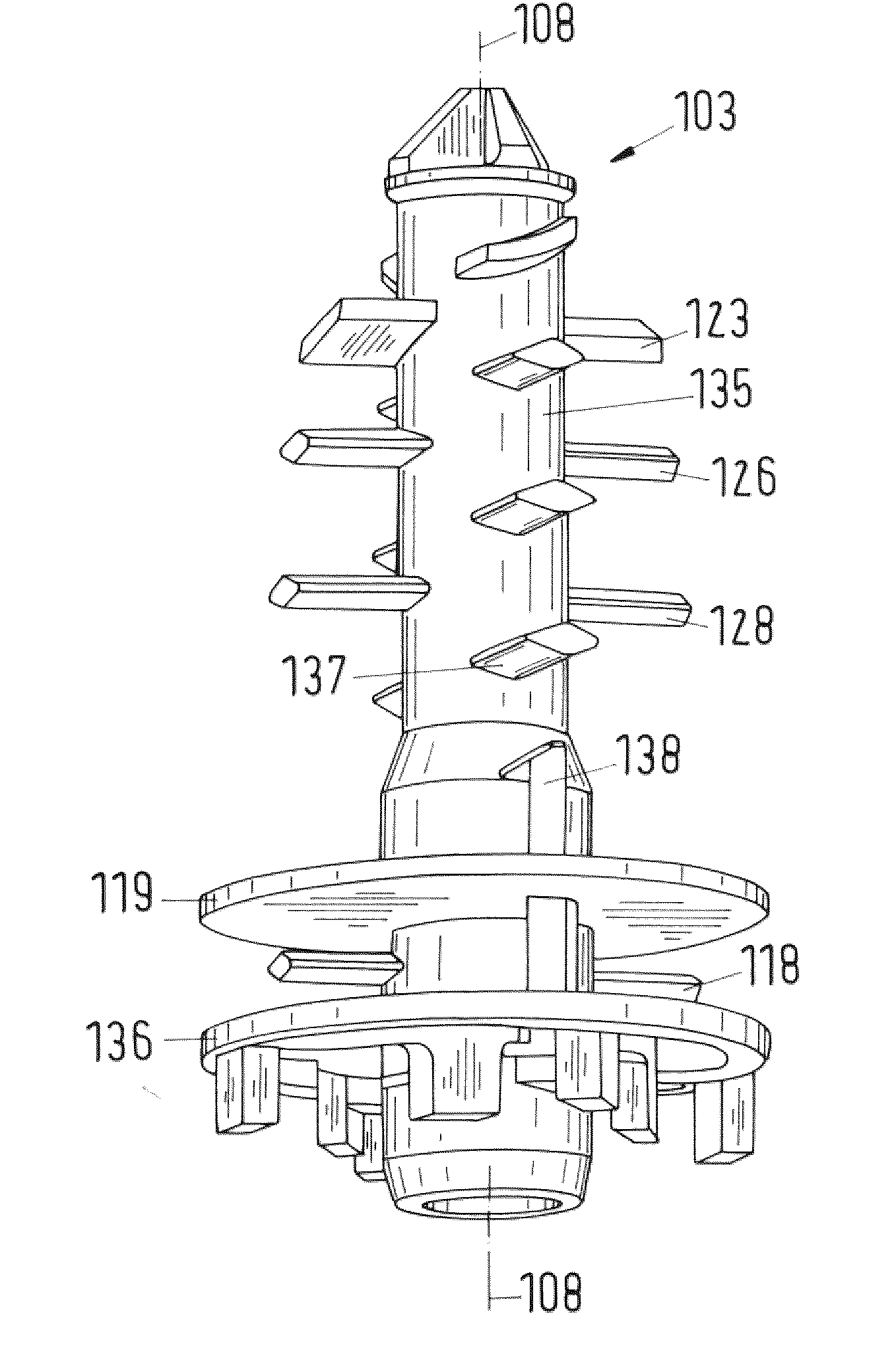

[0038] figure 1 A dynamic mixer for multiple fluid components is shown. The dynamic mixer 1 has a housing 2 and a rotor element 3 arranged rotatably about a rotor axis 8 in the housing 2 . In this embodiment, the housing 2 is constructed in two subsections, comprising a first housing subsection 4 and a second housing subsection 5 in which there is an inlet for the components, The second housing subsection is used to produce a mixture from a plurality of fluid components. As soon as the rotor element 3 is accommodated in the second housing part 5 , the first housing part is connected to the second housing part by means of a snap-in connection, a snap connection or a welded connection. The first housing subsection 4 has at least one inlet 12 , 13 for each component. The inlets 12 , 13 can have different diameters depending on the desired mixing ratio of the components. The inlets open into corresponding inlet channels 10 , 11 which are arranged in the first housing subsecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com